Filter by

System of Measurement

Shaft Type

Thread Size

Fastener Head Type

Pin Type

Material

End Type

Rate of Taper

Specifications Met

Thread Length

End Shape

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Hardness

REACH

RoHS

Breaking Strength

Minimum Hardness

Thread Type

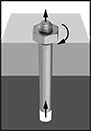

Threaded Taper Pins

Inch

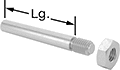

Lg. | Small End Dia. | Rate of Taper | Thread Lg. | Thread Size | Min. Hardness | Breaking Strength | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

12L14 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 Taper Pin—1.03" Large End Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.947" | 1:48 | 1 9/32" | 7/8"-14 | Not Rated | Not Rated | ASME B18.8.2 | 1 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 0.905" | 1:48 | 1 9/32" | 7/8"-14 | Not Rated | Not Rated | ASME B18.8.2 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 0.863" | 1:48 | 1 9/32" | 7/8"-14 | Not Rated | Not Rated | ASME B18.8.2 | 1 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 0.822" | 1:48 | 1 9/32" | 7/8"-14 | Not Rated | Not Rated | ASME B18.8.2 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

13 Taper Pin—1.239" Large End Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 1.031" | 1:48 | 1 9/32" | 7/8"-14 | Not Rated | Not Rated | ASME B18.8.2 | 1 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Hole Location Gauges

Thread Size | Thread Type | Hardness | Material | Each | ||

|---|---|---|---|---|---|---|

| 7/8"-14 | UNF | Rockwell C60 | Tool Steel | 0000000 | 0000000 |