Filter by

Spindle Shank Type

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Column Feed Handle Mounting Location

T-Tracks

Mount tracks to any flat surface or embed them to add fixturing to saw tables, CNC routers, or drill presses. They can also be used as general purpose hangers or attachment points.

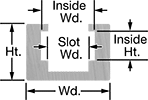

Single Profile Straight T-Tracks

|  |

Inside | Mounting Holes | For Mounting Screw | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | Slot Wd. | Width | Height | Mounting Fasteners Included | Number of | Center-to-Center | Size | Head Style | Material | Each | ||

| 18" | 3/4" | 1/2" | 3/8" | 1/2" | 1/4" | No | 6 | 3" | No. 8 | Pan | Anodized Aluminum | 0000000 | 00000 | |

| 24" | 3/4" | 1/2" | 3/8" | 1/2" | 1/4" | No | 8 | 3" | No. 8 | Pan | Anodized Aluminum | 0000000 | 00000 | |

| 36" | 3/4" | 1/2" | 3/8" | 1/2" | 1/4" | No | 12 | 3" | No. 8 | Pan | Anodized Aluminum | 0000000 | 00000 | |

| 48" | 3/4" | 1/2" | 3/8" | 1/2" | 1/4" | No | 16 | 3" | No. 8 | Pan | Anodized Aluminum | 0000000 | 00000 | |

Hex Head Screws

T-Nuts

Locknuts

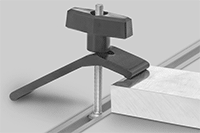

Hold-Down Clamps

|

Hold-down clamps slide along a T-track and secure a workpiece. Tighten with a turn of the knob. Mount them to the track using a hex head screw.

For Max. Workpiece Thk. | Lg. | Wd. | Material | Each | ||

|---|---|---|---|---|---|---|

| 2 1/2" | 4 1/4" | 1" | Steel | 0000000 | 00000 |

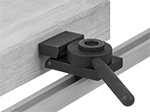

Cam Clamps

|

Cam clamps slide along a T-track and secure a workpiece from the side, so they don’t block access to the top of it. For a tight grip, they have an angled jaw that applies focused pressure as you turn the handle. They’re often used to hold workpieces on CNC machines.

Lg. | Wd. | Material | Each | ||

|---|---|---|---|---|---|

| 1 3/8" | 2 3/16" | Steel | 0000000 | 000000 |

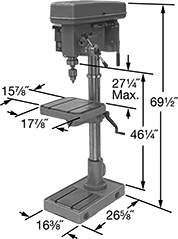

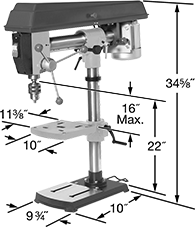

Economy Bench-Mount Drill Presses

|  |  |

10" Maximum Workpiece Diameter | 13" Maximum Workpiece Diameter | 15" Maximum Workpiece Diameter |

Use for drilling holes in metal workpieces and mount to a work surface to save floor space.

Drill Presses | Replacement Drill Press Spring Caps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Workpiece Dia. | Max. Table Cap., lb. | For Max. Drill Bit Size for Cast Iron | For Max. Bit Shank Size | Max. No-Load Rotational Speed, rpm | Chuck Key Included | No. of Speeds | Spindle Taper No. | Spindle Travel | Motor Power, hp | Motor Current, amp | Wt., lb. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Jacobs-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 70 | 1/2" | 1/2" | 3,070 | Yes | 5 | Jacobs 33 | 2 1/2" | 1/3 | 4.1 | 70 | 00000000 | 0000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13" | 80 | 1/2" | 1/2" | 3,100 | Yes | 12 | Jacobs 3 | 3 1/8" | 1/2 | 5 | 110 | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC/240V AC—Single-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Morse-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 100 | 5/8" | 5/8" | 3,450 | Yes | 16 | Morse 2 | 5" | 1/2 | 7.3 | 150 | 0000000 | 00000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Bench-Mount Drill Presses for Small Holes

|

Use for drilling small holes. A sensitive belt-drive motor reduces drill breakage and damage.

Drill Presses | Replacement Belts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Workpiece Dia. | For Max. Drill Bit Size for Steel | For Max. Bit Shank Size | Max. No-Load Rotational Speed, rpm | Chuck Mfr. | No. of Speeds | Spindle Taper No. | Spindle Travel | Motor Power, hp | Motor Current, amp | Wt., lb. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Jacobs-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1/8" | 1/8" | 20,000 | Albrecht | Variable | Jacobs 0 | 1 1/2" | 1/5 | 2 | 25 | 0000000 | 000000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Floor-Mount Drill Presses

|  |

18 1/8" Maximum Workpiece Diameter | 20" Maximum Workpiece Diameter |

The weight and rigidity of these presses prevent vibration so you can maintain close tolerances for high-quality metal drilling. Turn the dial on these drill presses while they are running to get the optimum speed for your job.

20" Maximum Workpiece Diameter—Drill presses with 20" maximum workpiece diameter have a safety guard that swings away for easy tool changes.

Max. Workpiece Dia. | Max. Table Cap., lb. | For Bit Shank Type | For Max. Drill Bit Size for Steel | For Max. Bit Shank Size | Max. No-Load Rotational Speed, rpm | Chuck Key Included | No. of Speeds | Spindle Taper No. | Spindle Travel | Motor Power, hp | Motor Current, amp | Current, amp | Wt., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

120V AC—Single-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Morse-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 1/8" | 200 | Hex, Round | 1 1/16" | 3/4" | 1,200 | Yes | Variable | Morse 3 | 5 3/8" | 2 | 6.8 | 6.8 | 675 | 000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC/240V AC—Single-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Morse-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20" | 250 | Hex, Round | 1 1/4" | — | 2,000 | No | Variable | Morse 3 | 6" | 2 | 25 | 25 | 649 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC/460V AC—Three-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Morse-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20" | 250 | Hex, Round | 1 1/4" | — | 2,000 | No | — | Morse 3 | 6" | 2 | 7 | 7 | 649 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

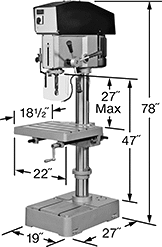

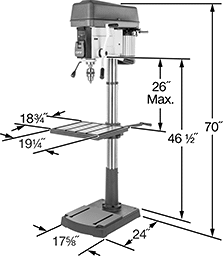

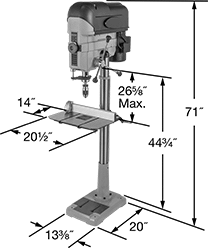

Adjustable-Speed Economy Floor-Mount Drill Presses

|  |  |

20" Maximum Workpiece Diameter | 15" Maximum Workpiece Diameter | 17" Maximum Workpiece Diameter |

Select from a number of speeds by repositioning the drive belt before starting the drill press.

Drill Presses | Replacement Drill Press Spring Caps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Workpiece Dia. | Max. Table Cap., lb. | For Bit Shank Type | For Max. Drill Bit Size for Steel | For Max. Bit Shank Size | Max. No-Load Rotational Speed, rpm | Chuck Key Included | No. of Speeds | Spindle Taper No. | Spindle Travel | Motor Power, hp | Motor Current, amp | Current, amp | Wt., lb. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC/240V AC—Single-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Morse-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20" | 75 | Round | 1 1/4" | 3/4" | 3,605 | Yes | 16 | Morse 2 | 6" | 1 1/2 | 14.2 | 14.2 | 274 | 000000000 | 000000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 100 | Hex, Round | 5/8" | 5/8" | 3,450 | Yes | 16 | Morse 2 | 5" | 1/2 | 7.3 | 7.3 | 165 | 0000000 | 00000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17" | 100 | Hex, Round | 5/8" | 5/8" | 3,450 | Yes | 16 | Morse 2 | 5" | 1 | 10 | 10 | 180 | 0000000 | 00000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Long-Reach Economy Bench-Mount Drill Presses

|

To accommodate large, odd-shaped pieces of material, the head of this drill press moves 12" forward and backward. It also tilts 45° left and 90° right (as viewed when facing the drill press).

For Max. Drill Bit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Workpiece Dia. | Max. Table Cap., lb. | For Bit Shank Type | Size for Steel | Size for Cast Iron | For Max. Bit Shank Size | Max. No-Load Rotational Speed, rpm | Chuck Key Included | No. of Speeds | Spindle Taper No. | Spindle Travel | Motor Power, hp | Motor Current, amp | Current, amp | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Morse-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33" | 70 | Hex, Round | 3/8" | 5/8" | 5/8" | 3,100 | Yes | 5 | Morse 2 | 3 5/32" | 1/2 | 5 | 4.8 | 95 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

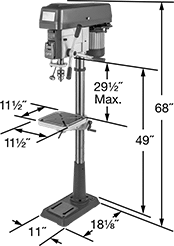

Variable-Speed Economy Floor-Mount Drill Presses

|

Turn the dial on this drill press while it is running to get the optimum speed for your job. A laser projects a crosshair at the point of bit contact and a digital readout displays the spindle speed.

Max. Workpiece Dia. | Max. Table Cap., lb. | For Bit Shank Type | For Max. Drill Bit Size for Steel | For Max. Bit Shank Size | Max. No-Load Rotational Speed, rpm | No. of Speeds | Spindle Taper No. | Spindle Travel | Motor Power, hp | Motor Current, amp | Current, amp | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

120V AC/240V AC—Single-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Morse-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 88 | Hex, Round | 5/8" | 5/8" | 3,000 | Variable | Morse 2 | 6" | 1 | 15 | 15 | 245 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

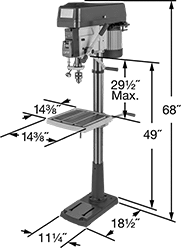

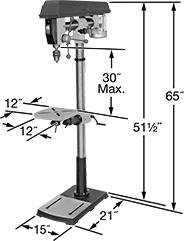

Long-Reach Economy Floor-Mount Drill Presses

|

To accommodate large, odd-shaped pieces of material, the head of this drill press moves 12" forward and backward. It also tilts 45° left and 90° right (as viewed when facing the drill press).

For Max. Drill Bit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Workpiece Dia. | Max. Table Cap., lb. | For Bit Shank Type | Size for Steel | Size for Cast Iron | For Max. Bit Shank Size | Max. No-Load Rotational Speed, rpm | Chuck Key Included | No. of Speeds | Spindle Taper No. | Spindle Travel | Motor Power, hp | Motor Current, amp | Current, amp | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single-Phase Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Morse-Taper Spindle Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33" | 50 | Hex, Round | 3/8" | 5/8" | 5/8" | 3,100 | Yes | 5 | Morse 2 | 3 5/32" | 1/2 | 5 | 4.8 | 143 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||