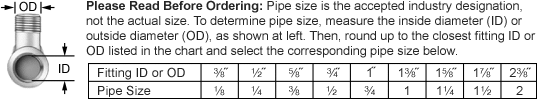

About Pipe Size and Spray Nozzles

More

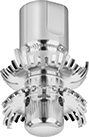

Rotating Tank-Washing Nozzles

By circulating their spray, these nozzles clean faster with more even coverage and less water than stationary tank-washing nozzles. The force of the liquid flowing through is what causes them to rotate, so the higher the pressure, the faster they will rotate. They spray in multiple directions to effectively rinse down tanks, drums, and small vessels.

316 stainless steel and PVDF nozzles have good resistance to chemicals and corrosion. PTFE nozzles have excellent resistance to chemicals and corrosion.

FDA-compliant nozzles can be used in the food industry.

Flow Rate, gpm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Specifications Met | Environment | Each | ||

1/8 NPT Female | |||||||||||||||

| A | 1.51 | 2.1 | 2.54 | 2 | __ | 5/8" | 1 1/4" | 80 | 200° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 0000000 |

| B | 3.5 | 5 | 6 | 4 1/2 | 0.02" | 11/16" | 1 9/16" | 100 | 480° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| B | 4 | 6 | 7 | 5 | 0.02" | 11/16" | 1 9/16" | 100 | 480° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

3/8 NPT Male | |||||||||||||||

| C | 3.5 | 5 | 6 | 5 | __ | 13/16" | 2 1/16" | 85 | 260° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| C | 5 | 7 | 8.5 | 5 | 0.09" | 13/16" | 2" | 70 | 250° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 110.40, FDA Compliant 21 CFR 177.1556, FDA Compliant 21 CFR 211.65 | Food Industry | 000000 | 000000 |

3/8 NPT Female | |||||||||||||||

| A | 12.1 | 17 | 20.8 | 10 | __ | 7/8" | 1 13/16" | 80 | 200° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| B | 6 | 8 | 10 | 5 1/2 | 0.03" | 1 1/16" | 2 3/8" | 100 | 480° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| B | 7 | 10 | 12 | 6 | 0.04" | 1 1/8" | 2 3/8" | 60 | 250° | Multiple Flat Stream | 180° | __ | __ | 00000000 | 000000 |

| B | 8.5 | 12 | 15 | 6 | 0.04" | 1 1/8" | 2 3/8" | 60 | 250° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

1/2 NPT Female | |||||||||||||||

| A | 14.3 | 20 | 24.3 | 10 | __ | 1 3/8" | 2 3/8" | 80 | 200° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

| A | 18.3 | 26 | 31.9 | 10 | __ | 1 3/8" | 2 3/8" | 80 | 200° | Multiple Flat Stream | 360° | __ | __ | 00000000 | 000000 |

3/4 NPT Female | |||||||||||||||

| D | 11 | 15 | 18 | 6 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 270° | FDA Compliant 21 CFR 177.2415 | __ | 000000 | 000000 |

| D | 11 | 15 | 18 | 6 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 360° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 13 | 18 | 22 | 7 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 270° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 16 | 22 | 27 | 7 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 360° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 21 | 30 | 37 | 8 1/2 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 270° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 21 | 30 | 37 | 8 1/2 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 360° | FDA Compliant 21 CFR 177.2415 | __ | 00000000 | 000000 |

| D | 32 | 45 | 55 | 10 | __ | 2 5/8" | 4 5/16" | 60 | 250° | Multiple Solid Stream | 360° | FDA Compliant 21 CFR 177.2415 | __ | 000000 | 000000 |

1 NPT Female | |||||||||||||||

| E | 35.5 | 50 | 61.1 | 11 | 0.17" | 3 7/8" | 2 15/16" | 60 | 190° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

Flow Rate, gpm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Pin Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Each | ||

1/2" Female Tube ID | ||||||||||||||

| B | 6 | 8 | 10 | 5 1/2 | 0.03" | 3/32" | 1 1/16" | 2 1/2" | 100 | 480° | Multiple Flat Stream | 360° | 00000000 | 0000000 |

| B | 7 | 10 | 12 | 6 | 0.04" | 3/32" | 1 1/16" | 2 1/2" | 100 | 480° | Multiple Flat Stream | 180° | 00000000 | 000000 |

| B | 8.5 | 12 | 15 | 6 | 0.04" | 3/32" | 1 1/16" | 2 1/2" | 100 | 480° | Multiple Flat Stream | 360° | 00000000 | 000000 |

Flow Rate, gpm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Specifications Met | Environment | Each | ||

1/4 NPT Female | |||||||||||||||

| F | 6.31 | 8.96 | 11 | 9 | 0.06" | 1 11/16" | 3 15/16" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 0000000 |

3/8 NPT Female | |||||||||||||||

| F | 6.31 | 8.96 | 11 | 9 | 0.06" | 1 11/16" | 3 15/16" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 13.4 | 19 | 23.4 | 11 | 0.06" | 1 15/16" | 4 1/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 15.2 | 21.5 | 26.3 | 14 | 0.06" | 1 15/16" | 4 1/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

1/2 NPT Female | |||||||||||||||

| F | 6.31 | 8.96 | 11 | 9 | 0.06" | 1 11/16" | 3 15/16" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 13.4 | 19 | 23.4 | 11 | 0.06" | 1 15/16" | 4 1/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 15.2 | 21.5 | 26.3 | 14 | 0.06" | 1 15/16" | 4 1/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 16.8 | 24.1 | 29.8 | 14 | 0.06" | 3" | 6 3/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

| F | 21.6 | 30.8 | 37.9 | 16 | 0.06" | 3" | 6 3/8" | 60 | 200° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.1550 | Food Industry | 0000000 | 000000 |

3/4 NPT Female | |||||||||||||||

| G | 13 | 18 | 22 | 8 | 0.07" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

| G | 15 | 21 | 26 | 8 | 0.08" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 180° | __ | __ | 0000000 | 000000 |

| G | 22 | 31 | 38 | 8 | 0.14" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

| G | 32 | 45 | 55 | 9 | 0.13" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 180° | __ | __ | 0000000 | 000000 |

| G | 32 | 45 | 55 | 9 | 0.18" | 2" | 3" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

1 NPT Female | |||||||||||||||

| G | 33 | 47 | 57.5 | 10 | 0.15" | 3" | 4" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

| G | 49.5 | 70 | 86 | 10 | 0.21" | 3" | 4" | 60 | 200° | Multiple Solid Stream | 360° | __ | __ | 0000000 | 000000 |

| G | 49.5 | 70 | 86 | 10 | 0.28" | 3" | 4" | 60 | 200° | Multiple Solid Stream | 180° | __ | __ | 0000000 | 000000 |

Flow Rate, gpm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Pattern | Spray Angle | Specifications Met | Environment | Each | ||

1/2 BSPP Female | |||||||||||||||

| H | 4 | 6 | 7 | 5 | 0.03" | 1 3/16" | 3" | 70 | 190° | Multiple Flat Stream | 360° | FDA Compliant 21 CFR 177.2510 | Food Industry | 00000000 | 000000 |

High-Impact Rotating Tank-Washing Nozzles

Internal gears create controlled motion as fluid moves through these nozzles, maintaining speed and producing large droplets to efficiently clean heavily soiled or large-diameter tanks. These nozzles rotate, so they produce more even coverage and clean faster than stationary tank nozzles while using less water. A multi-directional spray pattern makes these nozzles good for rinsing.

Flow Rate, gpm | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

316 Stainless Steel | |||||||||||

1/2 NPT Female | |||||||||||

| 6 | 8 | 10 | 11 1/2 | 1.73" | 2 11/16" | 5 13/16" | 215 | 200° | 360° | 0000000 | 000000000 |

3/4 NPT Female | |||||||||||

| 13 | 18 | 22 | 20 | 1.73" | 2 11/16" | 5 7/8" | 215 | 200° | 360° | 0000000 | 00000000 |

1 NPT Female | |||||||||||

| 30 | 42 | 51 | 26 | 1.73" | 2 11/16" | 5 7/16" | 215 | 200° | 360° | 0000000 | 00000000 |

Foam-Spray Rotating Tank-Washing Nozzles

Use these nozzles with detergent that’s diluted in water to create a rotating, multi-directional foam spray for effectively rinsing tanks, drums, and small vessels. Because they rotate, these nozzles clean faster and produce more even coverage than stationary tank-cleaning spray nozzles, typically while using less liquid. The force of the liquid flowing through these nozzles makes them spin, so they’ll spin faster at higher pressures.

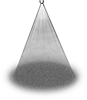

Tank-Washing Nozzles

To effectively rinse tanks, drums, and small vessels, these nozzles spray in multiple directions. The simplest style of tank-cleaning nozzle, they don't have any moving parts that will wear or need maintenance.

Brass and nylon nozzles have good corrosion resistance.

303 stainless steel nozzles are more chemical, corrosion, and abrasion resistant than brass nozzles.

316 stainless steel nozzles have excellent chemical and corrosion resistance.

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1/2 NPT Female | ||||||||||||

| 4 | 5 | 6 | 7 | 10 | 0.03" | 1 1/16" | 1 13/16" | 150 | 400° | 240° | 00000000 | 000000 |

| 6 | 8 | 9 | 11 | 21 | __ | 1" | 1 13/16" | 145 | 390° | 240° | 000000000 | 00000 |

| 13 | 16 | 18 | 22 | 10 | 0.06" | 1 1/16" | 1 13/16" | 150 | 400° | 240° | 00000000 | 00000 |

| 20 | 24 | 28 | 34 | 27 | __ | 1" | 1 13/16" | 145 | 390° | 240° | 000000000 | 00000 |

| 26 | 32 | 37 | 45 | 31 | __ | 1" | 1 13/16" | 145 | 390° | 240° | 000000000 | 00000 |

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1/2 NPT Female | ||||||||||||

| 4 | 5 | 6 | 7 | 10 | 0.03" | 1 1/16" | 1 13/16" | 150 | 400° | 240° | 00000000 | 0000000 |

| 6 | 8 | 9 | 11 | 23 | __ | 1" | 1 13/16" | 145 | 390° | 240° | 000000000 | 000000 |

| 13 | 16 | 18 | 22 | 10 | 0.06" | 1 1/16" | 1 13/16" | 150 | 400° | 240° | 00000000 | 000000 |

| 20 | 24 | 28 | 34 | 27 | 0.08" | 1 1/16" | 1 13/16" | 60 | 390° | 240° | 00000000 | 000000 |

| 26 | 32 | 37 | 45 | 31 | 0.09" | 1 1/16" | 1 13/16" | 60 | 390° | 240° | 000000000 | 000000 |

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1/8 NPT Female | ||||||||||||

| 3.5 | 4 | 5 | 6 | 7 | 0.03" | 13/16" | 1 1/2" | 60 | 390° | 360° | 000000000 | 0000000 |

1/2 NPT Female | ||||||||||||

| 40 | 48.5 | 56 | 68.5 | 11 | 0.07" | 2 1/2" | 3 5/16" | 60 | 390° | 360° | 000000000 | 000000 |

1 NPT Female | ||||||||||||

| 57 | 70 | 81 | 99 | 17 | 0.08" | 2 1/2" | 3 5/16" | 60 | 390° | 360° | 00000000 | 000000 |

2 NPT Female | ||||||||||||

| 147 | 180 | 208 | 255 | 18 | 0.12" | 3 1/2" | 4 7/16" | 60 | 390° | 360° | 000000000 | 000000 |

Flow Rate, gpm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Pin Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

3/8" Female Tube ID | |||||||||||||

| 11 | 14 | 16 | 19.5 | 7 | 0.04" | 1/16" | 1 1/8" | 1 11/16" | 60 | 390° | 360° | 000000000 | 0000000 |

3/4" Female Tube ID | |||||||||||||

| 22 | 27 | 31 | 38 | 8 | 0.06" | 1/16" | 1 1/8" | 1 11/16" | 60 | 390° | 360° | 000000000 | 000000 |

| 40 | 48.5 | 56 | 68.5 | 11 | 0.07" | 3/32" | 2 9/16" | 3 5/16" | 70 | 390° | 360° | 000000000 | 000000 |

1" Female Tube ID | |||||||||||||

| 57 | 70 | 81 | 99 | 17 | 0.08" | 1/16" | 2 9/16" | 3 5/16" | 60 | 390° | 360° | 000000000 | 000000 |

1 1/2" Female Tube ID | |||||||||||||

| 90 | 110 | 127 | 155.5 | 18 | 0.12" | 1/16" | 2 9/16" | 3 5/16" | 60 | 390° | 360° | 000000000 | 000000 |

2" Female Tube ID | |||||||||||||

| 147 | 180 | 208 | 255 | 18 | 0.13" | 1/16" | 3 9/16" | 4 3/8" | 60 | 390° | 360° | 000000000 | 000000 |

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 30 psi | @ 40 psi | @ 60 psi | For Max. Tank Dia., ft. | Orifice Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Each | |

1/2 NPT Female | ||||||||||||

| 3.9 | 4.7 | 5.5 | 6.7 | 5 | 0.03" | 1 3/16" | 1 3/4" | 150 | 200° | 240° | 000000000 | 0000000 |

| 12.5 | 15.1 | 17.7 | 22 | 5 | 0.06" | 1 3/16" | 1 3/4" | 150 | 200° | 240° | 000000000 | 000000 |

3/4 NPT Female | ||||||||||||

| 26 | 31.5 | 37 | 46 | 5 | 0.09" | 1 13/16" | 2 7/16" | 150 | 200° | 240° | 000000000 | 000000 |

Clog-Resistant Tank-Washing Nozzles

Avoid clogs while rinsing tanks, drums, and small vessels. These nozzles have a unique internal and external design, so particles in liquid pass through instead of getting stuck. To effectively rinse down tanks and other containers, they spray in multiple directions. But, compared to standard tank-washing nozzles, they produce larger droplets and have a less precise spray pattern. These nozzles don't have any moving parts that will wear or need maintenance.

Brass nozzles have good corrosion resistance.

316 stainless steel nozzles are more chemical and corrosion resistant than brass nozzles.

Flow Rate, gpm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 20 psi | @ 40 psi | @ 60 psi | @ 400 psi | For Max. Tank Dia., ft. | Orifice Dia. | For Max. Particle Dia. | Overall Wd. | Max. Pressure, psi | Max. Temp., °F | Lg. | Each | |

180° Spray Angle | ||||||||||||

Brass | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 450° | 2 7/8" | 0000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 450° | 2 15/16" | 0000000 | 00000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 450° | 2 15/16" | 0000000 | 00000 |

316 Stainless Steel | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 800° | 2 7/8" | 00000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 800° | 2 7/8" | 00000000 | 000000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 800° | 2 7/8" | 00000000 | 000000 |

270° Spray Angle | ||||||||||||

Brass | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 450° | 3 5/8" | 0000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 450° | 3 5/8" | 0000000 | 000000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 450° | 3 5/8" | 0000000 | 000000 |

1/2 NPT Male | ||||||||||||

| 17 | 24.1 | 29.5 | 76.2 | 9 | 0.41" | 0.17" | 7/8" | 400 | 450° | 4 1/4" | 0000000 | 000000 |

316 Stainless Steel | ||||||||||||

3/8 NPT Male | ||||||||||||

| 4.2 | 6 | 7.3 | 19 | 2 1/2 | 0.19" | 0.13" | 3/4" | 400 | 800° | 3 5/8" | 00000000 | 000000 |

| 7.5 | 10.6 | 13 | 33.5 | 5 | 0.25" | 0.13" | 3/4" | 400 | 800° | 3 5/8" | 00000000 | 000000 |

| 11.7 | 16.5 | 20.2 | 52.2 | 7 | 0.31" | 0.13" | 3/4" | 400 | 800° | 3 5/8" | 00000000 | 000000 |

1/2 NPT Male | ||||||||||||

| 17 | 24.1 | 29.5 | 76.2 | 9 | 0.41" | 0.17" | 7/8" | 400 | 800° | 4 1/4" | 00000000 | 000000 |

360° Spray Angle | ||||||||||||

316 Stainless Steel | ||||||||||||

3/4 NPT Female | ||||||||||||

| 30 | 42 | Not Rated | Not Rated | 8 | 0.3" | 0.25" | 2 3/8" | 40 | 200° | 3 9/16" | 00000000 | 000000 |

1 NPT Female | ||||||||||||

| 70.6 | 100 | Not Rated | Not Rated | 10 | 0.25" | 0.3" | 2 3/8" | 40 | 200° | 4" | 00000000 | 000000 |

Sanitary Tank-Washing Nozzles

Certified by 3-A to meet sanitary design standards, these nozzles have a 360° spray pattern to effectively rinse tanks and vessels in food, beverage, and pharmaceutical environments. Their one-piece design means there are no moving parts to maintain, making them good for clean-in-place (CIP) systems.

Made from 316 stainless steel, these nozzles will not corrode from frequent washdowns with harsh cleaners and sanitizers. All are self-draining with polished surfaces and a pin connection, which means they have no threads, to reduce the risk of bacteria growth.

These nozzles can be installed in any position. Slip them over your supply tube and secure them in place with the pin. Your supply tube must have a through-hole that matches the pin diameter.

Flow Rate, gpm | Smoothness, Ra | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tube Connection Type | @ 15 psi | @ 25 psi | @ 40 psi | For Max. Tank Dia., ft. | Pin Dia. | Overall Wd. | Lg. | Max. Pressure, psi | Max. Temp., °F | Spray Angle | Interior | Exterior | Specifications Met | Each | |

316 Stainless Steel | |||||||||||||||

3/4" Female Tube ID | |||||||||||||||

| Pin | 31 | 40 | 51 | 10 | 1/8" | 1 1/2" | 2 1/2" | 40 | 400° | 360° | 32 | 32 | 3-A Certified 78-01 | 0000000 | 0000000 |

1" Female Tube ID | |||||||||||||||

| Pin | 31 | 40 | 51 | 13 | 1/8" | 2" | 3 5/16" | 40 | 400° | 360° | 32 | 32 | 3-A Certified 78-01 | 0000000 | 000000 |

1 1/2" Female Tube ID | |||||||||||||||

| Pin | 31 | 40 | 51 | 13 | 3/16" | 2 1/2" | 4 1/4" | 40 | 400° | 360° | 32 | 32 | 3-A Certified 78-01 | 0000000 | 000000 |