How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

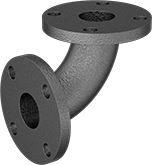

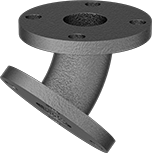

FM-Approved Iron Pipe Fittings with Flanged Ends

FM approved, these fittings are suitable for use in fire-protection systems. All have flat-surface flanged ends that only mate to another same-size flat-surface flange, pump, or valve with a gasket (sold separately) to create an access point in a pipeline. Use them in noncorrosive areas.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: FM Approved, UL Listed, ASTM A126, ASTM B307, Fed. Spec. WW-F-406, ASME B16.1, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Flanges: Use Class 150 steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 0000000 | 0000000 |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 0000000 | 000000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 0000000 | 000000 |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 0000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: FM Approved, UL Listed, ASTM A126, ASTM B307, Fed. Spec. WW-F-406, ASME B16.1, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Flanges: Use Class 150 steel

Drain, Waste, and Vent ABS Pipe Flanges for Chemicals

- For Use With: Sodium Hydroxide

- Max. Temperature: 180° F

- Specifications Met: ASTM D2661, ASTM D3311, ASTM D3965, ASTM F1498

- Pipe NIpples and Pipe: Use Schedule 40 ABS Plastic

- Fittings: Use Schedule 40 ABS Plastic

These Schedule 40 flanges are an economical choice for gravity-flow chemical waste systems. Flanges are ABS plastic, which has excellent strength and impact resistance and good chemical resistance. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. They have socket-connect ends that attach to unthreaded pipe or another socket-connect fitting with ABS cement (also known as solvent weld). They meet ASTM D2661, ASTM D3311, ASTM D3965, and ASTM F1498 specifications and testing requirements for material quality and product dimensions.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

Aboveground Standard-Wall PVC Pipe Flanges for Drain, Waste, and Vent

- For Use With: Water

- Max. Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D2665

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Fittings: Use Schedule 40 PVC Plastic

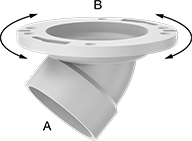

Also known as Schedule 40 flanges, these are the industry standard for gravity-flow drain, waste, and vent (DWV) applications. They are PVC for good corrosion resistance. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. They have socket-connect ends that attach to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld). Flanges meet ASTM D1784 and ASTM D2665 specifications and testing requirements for material quality.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

Flanged Ultra-High-Vacuum Fittings for Stainless Steel Tubing

- For Use With: Air

- Temperature Range:

Flanges: -300° to 800° F

Gaskets: Not Rated - Tubing: Use with 304/304L and 316/316L stainless steel

- Specifications Met:

Flanges: ASTM A240, ASTM E45, ASTM E12

Gaskets: ASTM B152-179, ASTM F68

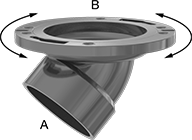

Create access points in ultra-high-vacuum lines or chambers by bolting two same-size flanges together with a copper gasket (sold separately) between them. The flanges’ sharp edges dig into the copper gasket and form an extremely tight seal, which means they handle higher vacuum pressures than other high-vacuum fittings with rubber gaskets. Also known as CF, Conflat, and UHV fittings, use them in vacuum coating, heat treating, and drying applications, as well as for leak testing and analyzing gases. They’re stainless steel so they resist rusting.

Fittings with a rotating flange turn so you can easily match up the bolt holes with another flange that may be misaligned.

Bolt kits are required to make a complete connection.

Bolt Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Max. Vacuum | Material | Appearance | Each | |

Rotating | |||||||||||||

| 3/4" | 1 21/64" | 16 | CF | 1 1/16" | 11/64" | 6 | No | 2 | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 0000000 |

| 1 1/2" | 2 3/4" | 40 | CF | 2 5/16" | 17/64" | 6 | No | 2 | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

| 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 2 | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

| 4" | 6" | 100 | CF | 5 1/8" | 21/64" | 16 | No | 4 | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

| For Flange OD | For High-Vacuum Flange Size | Bolt Dia. | Thread Size | No. of Bolts Included | No. of Nuts Included | No. of Washers Included | Bolt Material | Each | |

| 1 21/64" | 16 | 0.164" | 8-32 | 6 | 6 | 12 | 18-8 Stainless Steel | 0000000 | 00000 |

| 2 3/4" | 40 | 1/4" | 1/4"-28 | 6 | 6 | 12 | 18-8 Stainless Steel | 0000000 | 00000 |

| 4 1/2" | 63 | 5/16" | 5/16"-24 | 8 | 8 | 16 | 18-8 Stainless Steel | 0000000 | 00000 |

| 6" | 100 | 5/16" | 5/16"-24 | 16 | 16 | 32 | 18-8 Stainless Steel | 0000000 | 00000 |