How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About On/Off Valves

More

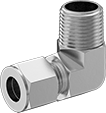

Ultra-Corrosion-Resistant Yor-Lok Fittings for Nickel Alloy Tubing

- For Use With: Acetic Acid, Air, Bleach, Cutting Oil, Diesel Fuel, Formic Acid, Fuel Oil, Gasoline, Hydraulic Fluid, Iron Chlorides, Mineral Oil, Salt Water, Steam, Water

- Temperature Range: 0° to 1000° F

- Tubing: Use with seamless soft C276 nickel

- Specifications Met: ASME B31.3

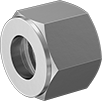

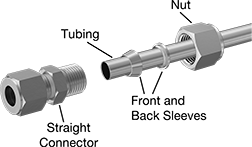

With the best corrosion resistance of any metal tube fittings we offer, these C276 nickel Hastelloy fittings stand up to aggressive chemicals and resist pitting and cracking from stress. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They include a nut with two sleeves (ferrules). The sleeves bite into tubing as you tighten the nut, creating a strong, leak-resistant seal. Fittings are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

Stainless Steel Push-to-Connect Tube Fittings for Chemicals

(SAE Straight) Male

Threads with Gasket

- For Use With: Alcohol, Bleach, Lubricated Air, Nitric Acid, Sodium Carbonate, Sulfuric Acid

- Temperature Range: 0° to 175° F

- Tubing: Use with firm or hard (Durometer 80A-60D) FEP, polyethylene, or PTFE plastic

Fittings are 316 stainless steel, which has excellent chemical resistance and is more durable than plastic. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. Instead of a release ring, these fittings have a release sleeve that slides back to disconnect tubing.

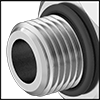

Metric and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

(SAE Straight) Male

Threads with Gasket

| For Tube OD | Pipe Size | Thread Size | Thread Pitch, mm | Material | Gasket Material | Max. Pressure | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4" | 1/8 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 0000000 | 000000 |

| 1/4" | 1/4 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 3/8 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 1/4 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 00000000 | 000000 |

| 3/8" | 3/8 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 00000000 | 000000 |

| 3/8" | 1/2 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 00000000 | 000000 |

| 1/2" | 1/4 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 00000000 | 000000 |

| 1/2" | 1/2 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 0000000 | 000000 |

| 6mm | 1/8 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 00000000 | 00000 |

| 6mm | 1/4 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 00000000 | 00000 |

| 8mm | 1/4 | __ | __ | 316 Stainless Steel | __ | 345 psi @ 72° F | 00000000 | 00000 |

Metric Threads | ||||||||

| 1/4" | __ | M5 | 0.8 | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 00000000 | 00000 |

| 1/4" | __ | M7 | 1 | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 00000000 | 00000 |

| 1/4" | __ | M10 | 1 | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 00000000 | 00000 |

| 4mm | __ | M3 | 0.5 | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 0000000 | 00000 |

| 4mm | __ | M5 | 0.8 | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 00000000 | 00000 |

| 6mm | __ | M5 | 0.8 | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 00000000 | 00000 |

| 6mm | __ | M10 | 1 | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 00000000 | 00000 |

| 10mm | __ | M10 | 1 | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 00000000 | 000000 |

UN/UNF (SAE Straight) Threads | ||||||||

| 1/4" | __ | 10-32 | __ | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 00000000 | 00000 |

| 4mm | __ | 10-32 | __ | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 0000000 | 00000 |

| 6mm | __ | 10-32 | __ | 316 Stainless Steel | Viton® Fluoroelastomer Rubber | 345 psi @ 72° F | 00000000 | 00000 |

| For Tube OD | Material | Max. Pressure | Each | |

| 1/4" | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 000000 |

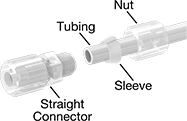

Compression Fittings for Plastic Tubing—Chemicals

- For Use With: PFA Plastic: Hydrochloric Acid, Sulfuric Acid

PTFE Plastic: Alcohol, Ammonia, Benzoic Acid, Bleach, Bromine, Coolant, Fluoboric Acid, Hydrochloric Acid, Hydrofluoric Acid, Nitric Acid, Organic Solvents, Sodium Carbonate, Sulfuric Acid - Temperature Range: PFA Plastic: 0° to 350° F

PTFE Plastic: -40° to 185° F - Tubing: PFA Plastic: Use with hard (Durometer 50D-65D) PFA or PTFE plastic

PTFE Plastic: Use with hard (Durometer 60D) PFA or PTFE plastic

A sleeve (ferrule) compresses the tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. Fittings that include a gripper sleeve on the tubing create an even tighter seal.

PTFE fittings are highly resistant to most acids, alcohols, detergents, and solvents. They’re made by machining. Their nut is made of PVDF, which is resistant to halogens such as chlorine and bromine, strong acids such as hydrofluoric and nitric acids, and organic solvents.

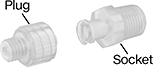

Luer Lock Tube Couplings for Plastic and Rubber Tubing—Chemicals

- For Use With: Acetic Acid, Bleach, Ethanol, Hydrochloric Acid, Nitric Acid, Phosphoric Acid, Sulfuric Acid

- Tubing: Use with soft (Durometer 40A-65A) PVC plastic or silicone rubber

A staple in labs, these couplings are highly versatile, fitting any luer lock plug, socket, syringe, or needle. They lock together with a push and turn, so they work well in lines that are frequently disconnected. Use them in low-pressure applications. They have a compact body for installation in tight spaces. Made of PVDF, they resist most acids, alcohols, and organic solvents. PVDF is also known as Kynar.

Note: For a complete coupling, order a plug and a socket.

| Pipe Size | Material | Color | Clarity | Max. Pressure | Pkg. Qty. | Pkg. | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/8 | PVDF Plastic | White | Semi-Clear | Not Rated | 10 | 0000000 | 000000 |

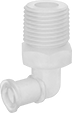

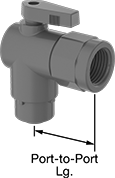

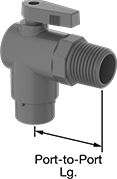

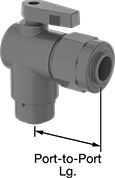

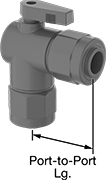

On/Off Valves with Push-to-Connect Fittings for Chemicals

Push to Connect ×

Push to Connect

Insert tubing into the fittings on these valves—no heat, solder, or flux required. To withstand aggressive and corrosive solutions, they have a chemical-resistant fluoroelastomer seal and a plastic body.

Full-port valves do not restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With:

Connector: Air, Argon, Carbon Dioxide, Citric Acid, Deionized Water, Ethylene Glycol, Helium, Isopropyl Alcohol, Krypton, Natural Gas, Neon, Nitrogen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hypochlorite, Sulfuric Acid, Water, Xenon

Adapter: Air, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Nitrogen, Oil, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hypochlorite, Sulfuric Acid, Water, Xylene - Ball Material: PVDF Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: Fluoroelastomer Rubber

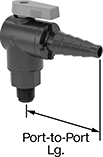

| Pipe Size | For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Port Type | Port-to-Port Lg. | Each | |

90° Elbow Adapter, Push to Connect × Female NPT Threaded | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Full | 1 1/4" | 000000000 | 000000 |

| 1/4 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 1/4" | 000000000 | 00000 |

| 1/4 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 1/4" | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 1/4" | 000000000 | 00000 |

| 3/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 1/4" | 000000000 | 00000 |

| 3/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 1/4" | 000000000 | 00000 |

| 1/2 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | 1 5/8" | 000000000 | 00000 |

| 1/2 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | 1 5/8" | 000000000 | 00000 |

| 1/2 | 1/2" | 2.8 | 125 psi @ 140° F | 35° to 140° | Standard | 1 5/8" | 000000000 | 00000 |

90° Elbow Adapter, Push to Connect × Male NPT Threaded | ||||||||

| 1/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 11/16" | 000000000 | 00000 |

| 1/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 11/16" | 000000000 | 00000 |

| 1/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 11/16" | 000000000 | 00000 |

| 1/4 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 11/16" | 000000000 | 00000 |

| 1/4 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 11/16" | 000000000 | 00000 |

| 1/4 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 11/16" | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 3/4" | 000000000 | 00000 |

| 3/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 3/4" | 000000000 | 00000 |

| 3/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 3/4" | 000000000 | 00000 |

| 1/2 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | 1 3/4" | 000000000 | 00000 |

| 1/2 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | 1 3/4" | 000000000 | 00000 |

| 1/2 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | 1 3/4" | 000000000 | 00000 |

90° Elbow Adapter, Push to Connect × Push to Connect | ||||||||

| __ | 1/4" × 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 3/8" | 000000000 | 00000 |

| __ | 1/4" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 11/16" | 000000000 | 00000 |

| __ | 3/8" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 11/16" | 000000000 | 00000 |

90° Elbow Connector, Push to Connect × Push to Connect | ||||||||

| __ | 1/4" × 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 3/8" | 000000000 | 00000 |

| __ | 3/8" × 3/8" | 1.9 | 125 psi @ 140° F | 35° to 140° | Full | 1 3/8" | 000000000 | 00000 |

| __ | 1/2" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 1 11/16" | 000000000 | 00000 |

On/Off Valves with Barbed Fittings for Chemicals

Barbs grip onto tubing, providing a secure hold. To withstand aggressive and corrosive solutions in chemical-processing applications, these valves have a plastic body and a chemical-resistant seal.

Polypropylene valves offer good heat resistance. Use them in systems that connect to a heater.

Lever handles show the valve’s position.Valves with tapered barbs can be used with multiple tube sizes.

Full-port valves do not restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With: Air, Argon, Carbon Dioxide, Citric Acid, Deionized Water, Ethylene Glycol, Fuel Oil, Helium, Isopropyl Alcohol, Krypton, Natural Gas, Neon, Nitrogen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hypochlorite, Sulfuric Acid, Water, Xenon

- Ball Material: Polypropylene Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: Fluoroelastomer Rubber

| Pipe Size | For Tube ID | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Port Type | Port-to-Port Lg. | Each | |

NPT Male × Tapered Barbed | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 3/8", 1/2", 5/8" | 1.4 | 125 psi @ 140° F | 40° to 140° | Full | 2 5/16" | 00000000 | 000000 |