How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Low-Pressure Press-Connect Steel Unthreaded Pipe Fittings

- For Use On:

EPDM Rubber O-Ring: Ethylene Glycol, Propylene Glycol, Water

Buna-N Rubber O-Ring: Air, Lubricants, Propane, Fuel Oil, Natural Gas, Diesel Fuel - Specifications Met:

EPDM Rubber O-Ring: ASME B31,1, ASME B31.3, ASME B31.9, FM 1920, UL 213

Buna-N Rubber O-Ring: ASME B31.1, ASME B31.3, ASME B31.9, ANSI LC4/CSA 6.32, International Fuel Gas Code - Maximum Pressure:

EPDM Rubber O-Ring: 200 psi @ 72° F

Buna-N Rubber O-Ring: 125 psi @ 72° F - Pipe Nipples and Pipe: Use Schedule 40 Steel

- Flanges: Use Class 150 Steel

Crimp these fittings onto steel pipe to form a tightly sealed connection that’s faster than threading or welding and doesn’t require heat. An internal gripping ring and rubber O-ring create a secure seal when crimped. They are designed to leak if fittings have not been crimped; a colored dot marks the leak path so it's easy to spot unsealed connections. These steel fittings are coated in zinc-nickel to resist corrosion, but will rust if frequently exposed to saltwater or harsh chemicals. They are comparable to Viega MegaPress steel fittings.

Fittings meet ASME B31 code requirements for use in pressure piping systems.

Buna-N rubber O-rings hold up to natural gas, propane, diesel fuel, lubricants, and other oils. Fittings with these O-rings are often used in fuel gas systems and air lines. They meet the ANSI LC4/CSA 6.32 standard for fuel gas systems and comply with the International Fuel Gas Code.

Crimping tools seal fittings in less than five seconds. These tools are cordless, so you can take them to any job. Connect the jaw or ring that matches your pipe size to these tools, then pull the trigger to crimp the fitting. The pivoting head lets you access connections from any angle.

Battery | |||||||

|---|---|---|---|---|---|---|---|

| Voltage | No. Included | Cap., amp-hrs. | Battery Charger Included | Battery Charging Time, min. | Compatible With | Each | |

| 18V DC | 2 | 3 | Yes | 39 | Viega MegaPress Viega ProPress Viega ProPress XL-C | 00000000 | 000000000 |

Jaw and ring sets include three jaws, three rings, and one ring actuator jaw. Jaws are for pipe sizes 1/2 to 1; they fit directly into the crimping tool. Rings are for pipe sizes 1 1/4 to 2; clip the ring around the fitting and use the ring actuator jaw and crimping tool to press the open ends together.

For Pipe | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size | Material | For Manufacturer | For Manufacturer Model No. | Compatible With | Includes | Container Type | Each | |

| 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | Stainless Steel, Steel | Ridgid | RP 340 | Viega MegaPress | One Ring Actuator Jaw Three Jaws (1/2-1 Pipe Size) Three Rings (1 1/4-2 Pipe Size) | Carrying Case | 00000000 | 000000000 |

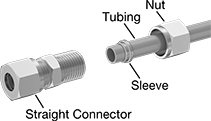

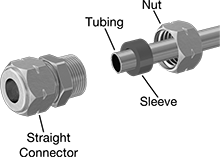

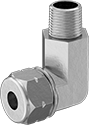

Nickel-Plated Brass Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Lubricants, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 550° F, except 90° elbow adapters with BSPP threads are 0° to 170° F

- Tubing: Use with copper

- Specifications Met: DIN 3861, except nuts meet DIN 3870

With a nickel-plated finish, these compression fittings resist corrosion better than plain brass fittings. They have a single sleeve (ferrule) made of plain brass that gently bites into copper tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. These fittings are also known as flareless fittings. All meet DIN standards for tube fitting dimensions.

Adapter, Tube × Male

Threaded Pipe (BSPP)

Adapter, Tube × Male

Threaded Pipe (BSPT)

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Pipe Size | Material | Maximum Pressure | Each | |

BSPP Threads | ||||||

| 4 | 1 | 1/8 | Nickel-Plated Brass | 1,800 psi @ 72° F | 00000000 | 00000 |

| 6 | 1 | 1/8 | Nickel-Plated Brass | 2,500 psi @ 72° F | 00000000 | 0000 |

| 6 | 1 | 1/4 | Nickel-Plated Brass | 2,500 psi @ 72° F | 00000000 | 0000 |

| 8 | 1 | 1/8 | Nickel-Plated Brass | 2,100 psi @ 72° F | 00000000 | 0000 |

| 8 | 1 | 1/4 | Nickel-Plated Brass | 2,100 psi @ 72° F | 00000000 | 0000 |

| 10 | 1 | 1/4 | Nickel-Plated Brass | 1,600 psi @ 72° F | 00000000 | 0000 |

| 12 | 1 | 3/8 | Nickel-Plated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

BSPT Threads | ||||||

| 4 | 1 | 1/8 | Nickel-Plated Brass | 1,800 psi @ 72° F | 0000000 | 0000 |

| 6 | 1 | 1/8 | Nickel-Plated Brass | 2,500 psi @ 72° F | 0000000 | 0000 |

| 6 | 1 | 1/4 | Nickel-Plated Brass | 2,500 psi @ 72° F | 0000000 | 0000 |

| 8 | 1 | 1/8 | Nickel-Plated Brass | 2,100 psi @ 72° F | 0000000 | 0000 |

| 8 | 1 | 1/4 | Nickel-Plated Brass | 2,100 psi @ 72° F | 0000000 | 0000 |

| 14 | 1 | 1/2 | Nickel-Plated Brass | 1,000 psi @ 72° F | 0000000 | 0000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Length, mm | Each | |

Short Nuts | ||||||

| 4 | 1 | Nickel-Plated Brass | 1,800 psi @ 72° F | 11 | 00000000 | 00000 |

| 6 | 1 | Nickel-Plated Brass | 2,500 psi @ 72° F | 12 | 00000000 | 000 |

| 8 | 1 | Nickel-Plated Brass | 2,100 psi @ 72° F | 12 | 00000000 | 000 |

| 10 | 1 | Nickel-Plated Brass | 1,600 psi @ 72° F | 16 | 00000000 | 0000 |

| 12 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 16 | 00000000 | 0000 |

| 14 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 19 | 00000000 | 0000 |

| 15 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 17 | 00000000 | 0000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Sleeve Material | Maximum Pressure | Each | |

| 4 | 1 | Brass | 1,800 psi @ 72° F | 00000000 | 00000 |

| 6 | 1 | Brass | 2,500 psi @ 72° F | 00000000 | 000 |

| 8 | 1 | Brass | 2,100 psi @ 72° F | 00000000 | 000 |

| 10 | 1 | Brass | 1,600 psi @ 72° F | 00000000 | 000 |

| 12 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

| 14 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

| 15 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

Vibration-Resistant Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Lubricants, Mineral Oil, Water

- Temperature Range: -30° to 270° F, except fluoroelastomer sleeves are -15° to 450° F

- Tubing: Use with copper

The sleeve (ferrule) in these fittings is rubber instead of metal, so it cushions the tubing and absorbs vibration while creating a tight seal. The sleeve aligns the tubing during installation. Fittings come with a nut and a sleeve. They are also known as flareless fittings. They are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | |||||

|---|---|---|---|---|---|

| 3/16" | 1/8 | Brass | 300 psi @ 72° F | 00000000 | 000000 |

| 1/4" | 1/8 | Brass | 300 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 1/4 | Brass | 300 psi @ 72° F | 00000000 | 00000 |

| 5/16" | 1/4 | Brass | 220 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 1/8 | Brass | 170 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 1/4 | Brass | 170 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 3/8 | Brass | 170 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 3/8 | Brass | 100 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 1/2 | Brass | 100 psi @ 72° F | 00000000 | 00000 |

| For Tube OD | Sleeve Color | Max. Pressure | Each | |

Buna-N Rubber | ||||

|---|---|---|---|---|

| 3/16" | Black with Green Stripe | 300 psi @ 72° F | 00000000 | 00000 |

| 1/4" | Black with Green Stripe | 300 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Black with Green Stripe | 220 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Black with Green Stripe | 170 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Black with Green Stripe | 100 psi @ 72° F | 00000000 | 0000 |

Fluoroelastomer Rubber | ||||

| 3/16" | Black with Red Stripe | 300 psi @ 72° F | 00000000 | 00000 |

| 1/4" | Black with Red Stripe | 300 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Black with Red Stripe | 220 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Black with Red Stripe | 170 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Black with Red Stripe | 100 psi @ 72° F | 00000000 | 00000 |