Filter by

Capacity

Flow Control Type

Export Control Classification Number (ECCN)

Overall Height

DFARS Specialty Metals

Electrical Connection

Maximum Pressure

Height

Battery-Powered Pistol-Grip Grease Guns

Grease Guns | Replacement Batteries | Replacement Chargers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/min | Nozzle Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cap., fl. oz. | High Pressure | Low Pressure | For NLGI Consistency Grade | Max. Grease Outlet Pressure, psi | Nozzle Lg. | Thread Type | Pipe/Thread Size | Gender | Batteries Included | Loading Method | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Standard Grease Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC Battery | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 1/2 | 2.6 | — | 00, 0, 1, 2 | 8,000 | 30" | NPTF UNEF | 1/8 7/16"-28 | Male Male | Yes | Bulk Filler Pump, Cartridge | 0000000 | 0000000 | 0000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20V DC Battery | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 6 | 4 | 1, 2 | 6,000 | 36" | NPTF UNF | 1/8 7/16"-20 | Male Male | Yes | Cartridge | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable-Interval Electric Oil-Dispensing Pumps

Overall | Mounting | For Max. Viscosity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pumps | Cap., qt. | Flow Duration, sec. | Flow Rate, fl oz/sec | Dispensing Interval, min. | Max. Oil Outlet Pressure, psi | Reservoir Material | Ht. | Wd. | Dp. | Voltage, V AC | Current, amp | Temp. Range, ° F | Hole Dia. | Fasteners Included | ISO Grade | SAE Grade | SSU Grade, SSU | AGMA Grade | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16"-24 UNF Female Oil Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3 1/8 | 1 to 180 | 0.1 | 3 to 999 | 100 | Plastic | 10 1/16" | 8 7/8" | 6 11/16" | 120 | 0.03 | 32 to 120 | 1/4" | No | 150 | 40 | 700 | 4 | 000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

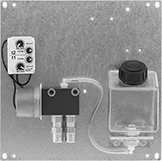

Precision Adjustable-Interval Electric Oil-Dispensing Pumps

|  |

2 Pumps | 4 Pumps |

Panel | For Max. Viscosity | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pumps | Cap. | oz. per Cycle, fl. oz. | Dispensing Interval | Max. Oil Outlet Pressure, psi | Ht. | Wd. | Reservoir Material | Pump Material | Voltage, V AC | Current, amp | Temp. Range, ° F | Mounting Fasteners Included | ISO Grade | SAE Grade | SSU Grade, SSU | AGMA Grade | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Female Oil Outlets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 16 fl. oz. | 0 to 0.005 | 1 min. to 24 hr. | 250 | 10 3/4" | 10 7/8" | Plastic | Aluminum | 120 | 0.06 | -15 to 120 | No | 220 | 90 | 1,000 | 5 | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 qt. | 0 to 0.005 | 1 min. to 24 hr. | 100 | 10 3/4" | 10 7/8" | Plastic | Aluminum | 120 | 0.06 | -15 to 120 | No | 220 | 90 | 1,000 | 5 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flood Coolant Dispensers

Nozzle | Dispensing Tip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate @ 30 psi, gpm | Flow On/Off Mechanism | Max. Pressure, psi | No. of Coolant Outlets | Lg. | Type | Material | Mount Method | Bend Radius | No. of | Orifice Dia. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Use With Air, Coolant, Cutting Oil, and Water | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | Handle | 50 | 1 | 8" | Flexible | Acetal | Magnetic | 2" | 3 | 1/16", 1/8", 1/4" | Acetal | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Droplet Coolant Dispensers

Coolant Outlet | Nozzle | Overall | Dispensing Tip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., fl. oz. | Droplets per min. | Max. Pressure, psi | No. of | Hose Lg., ft. | Hose Material | Lg. | Type | Material | Mount Method | Bend Radius | Ht. | Wd. | Dp. | Reservoir Dia. | Reservoir Material | Lg. | Material | Air Inlet Pressure, psi | For Max. SSU Viscosity Grade, SSU | Voltage, V AC | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Use With Coolant | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 2 to 16 | 125 | 2 | 6 | Polyurethane Plastic | 18" | Flexible | Acetal | Magnetic | 1 3/4" | 7 1/16" | 10 1/16" | 7 1/16" | 3 1/2" | Polyethylene | 1 1/2" | Brass | 60 to 125 | 200 | 120 | Adjustable Flow | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed-Interval Electric Oil-Dispensing Pumps

Overall | Mounting | For Max. Viscosity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pumps | Cap., qt. | oz. per Cycle, fl. oz. | Max. Oil Outlet Pressure, psi | Reservoir Material | Ht. | Wd. | Dp. | Voltage, V AC | Current, amp | Temp. Range, ° F | Hole Dia. | Fasteners Included | ISO Grade | SAE Grade | SSU Grade, SSU | AGMA Grade | Choose a Dispensing Interval, min. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16"-24 UNF Female Oil Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 1/8 | 0.1 to 0.2 | 40 | Plastic | 8 7/8" | 7 7/8" | 5 1/8" | 120 | 0.03 | 32 to 120 | 1/4" | No | 150 | 40 | 700 | 4 | 3 , 5 , 10 , 15 , 30 , 60 | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrically Operated Flow-Adjustment Valves

Oil Inlet | Oil Outlet | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Ht. | Wd. | Material | Voltage, V AC | Current, amp | Temp. Range, ° F | For Use With | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Top Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | PTF-SAE | Female | 1/8 | NPTF | Male | 3 9/32" | 4 1/4" | Brass | 120 | 0.1 | -30 to 250 | Oil | Glass Flow Sight | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Side Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | PTF-SAE | Female | 1/4 | NPTF | Male | 5 15/16" | 2 13/16" | Brass | 120 | 0.1 | -30 to 250 | Oil | Glass Flow Sight | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

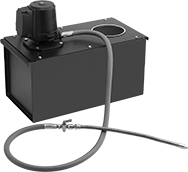

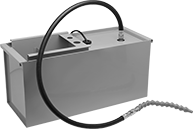

Flood Coolant Dispensers with Reservoir

|  |

Style A | Style B |

|  |

Style C | Style D |

Coolant Outlet | Nozzle | Reservoir | Dispensing Tip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Cap., gal. | Max. Flow Rate @ ft. of Head | Max. Pressure, psi | No. of | Hose Lg., ft. | Hose Material | Lg. | Type | Material | Bend Radius | Overall Ht. | Wd. | Dp. | Reservoir Material | Shut-Off Ht., ft. | Lg. | Material | For Max. SSU Viscosity Grade, SSU | Voltage, V AC | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Use With Coolant and Water | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 | 108 gph @ 1 ft. | 5 | 1 | 6 | Vinyl Plastic | 6" | Rigid | Polyethylene | — | 9 3/8" | 12" | 6" | Polypropylene | 11.5 | — | — | 100 | 120 | Adjustable Flow, Coolant Strainer | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5 | 210 gph @ 1 ft. | 4.3 | 1 | 6 | Vinyl Plastic | 12" | Flexible | Acetal | 1 1/2" | 8 1/2" | 16 7/8" | 11 1/4" | Polyethylene | 10.2 | — | — | 300 | 120 | Adjustable Flow, Coolant Strainer, Baffle, On/Off Valve | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5 | 325 gph @ 1 ft. | 5.2 | 1 | 6 | Vinyl Plastic | 12" | Flexible | Acetal | 1 1/2" | 8 1/2" | 16 7/8" | 11 1/4" | Polyethylene | 12.3 | — | — | 300 | 120 | Adjustable Flow, Coolant Strainer, Baffle, On/Off Valve | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5 | 500 gph @ 1 ft. | 7.5 | 1 | 6 | Vinyl Plastic | 12" | Flexible | Acetal | 1 1/2" | 8 1/2" | 16 7/8" | 11 1/4" | Polyethylene | 17.3 | — | — | 300 | 120 | Adjustable Flow, Coolant Strainer, Baffle, On/Off Valve | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 6 | 600 gph @ 1 ft. | 5.6 | 1 | 4 | Neoprene | 15" | Flexible | Steel | 3" | 15" | 18" | 9 1/2" | Steel | 14 | 1" | Brass | 500 | 120 | Adjustable Flow, Coolant Strainer, Baffle, On/Off Valve | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 10 | 600 gph @ 1 ft. | 5.6 | 1 | 4 | Neoprene | 15" | Flexible | Steel | 3" | 16 1/2" | 24" | 9 3/4" | Steel | 14 | 1" | Brass | 500 | 120 | Adjustable Flow, Coolant Strainer, On/Off Valve | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 10 | 500 gph @ 1 ft. | 7.5 | 1 | 4 | Buna-N | 12" | Flexible | Acetal | 2 1/4" | 12" | 25" | 10" | Steel | 17.3 | — | — | 300 | 120 | Adjustable Flow, Coolant Strainer, Baffle, On/Off Valve | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrically Operated Oil Dispensers with Flow-Adjustment Valve and Brush

Overall | Bristle | 120V AC 0.1 amp | 24V DC 0.4 amp | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Bowl Dia. | Brush Wd. | Ht. | Wd. | Ht. | Material | Housing Material | Bowl Material | Pressure Regulation Method | Max. Temp., ° F | Mounting Thread Size | Each | Each | |||

| 2 1/2 fl. oz. | 2" | 1 1/2" | 8" | 4 7/16" | 1 5/32" | Nylon | Aluminum | Plastic | Vented | 140 | 5/8"-18 | 0000000 | 0000000 | 0000000 | 0000000 | |

| 5 fl. oz. | 2 1/2" | 1 1/2" | 8 1/2" | 4 11/16" | 1 5/32" | Nylon | Aluminum | Plastic | Vented | 140 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |

| 9 fl. oz. | 3" | 1 1/2" | 9 5/16" | 5 3/8" | 1 5/32" | Nylon | Aluminum | Plastic | Vented | 140 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |

| 12 fl. oz. | 3" | 1 1/2" | 10 5/16" | 5 3/8" | 1 5/32" | Nylon | Aluminum | Plastic | Vented | 140 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |

| 16 fl. oz. | 3 1/2" | 1 1/2" | 10 5/16" | 5 15/32" | 1 5/32" | Nylon | Aluminum | Plastic | Vented | 140 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |

| 1 qt. | 4 1/4" | 1 1/2" | 11 3/4" | 5 13/16" | 1 5/32" | Nylon | Aluminum | Plastic | Vented | 140 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |

Electrically Operated Oil Dispensers with Flow-Adjustment Valve

Overall | 120V AC 0.1 amp | 24V DC 0.4 amp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Bowl Dia. | Ht. | Wd. | Housing Material | Bowl Material | Pressure Regulation Method | Max. Temp., ° F | Mounting Thread Size | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1/4" OD Oil Outlet Tubes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 fl. oz. | 2" | 5 9/16" | 4 1/2" | Aluminum | Plastic | Vented | 160 | 5/8"-18 | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 fl. oz. | 2 1/2" | 6 1/16" | 5" | Aluminum | Plastic | Vented | 160 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 fl. oz. | 3" | 6 7/8" | 5 5/16" | Aluminum | Plastic | Vented | 160 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 fl. oz. | 3" | 7 7/8" | 5 5/16" | Aluminum | Plastic | Vented | 160 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 fl. oz. | 3 1/2" | 7 7/8" | 5 5/8" | Aluminum | Plastic | Vented | 160 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 qt. | 4 1/4" | 9 5/16" | 5 11/16" | Aluminum | Plastic | Vented | 160 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 qt. | 5 1/2" | 11 5/16" | 6 7/16" | Aluminum | Plastic | Vented | 160 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 gal. | 5 1/2" | 16 5/16" | 6 3/4" | Aluminum | Plastic | Vented | 160 | 5/8"-18 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||