Filter by

Environment

Cover Material

For Push-Button Size

Inside Height

Hinge Material

Performance

Certification

With Knockouts

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Closure Screw Material

About Electrical Enclosures

Select the right electrical enclosure for your environment and the accessories you'll need to get it mounted and connected.

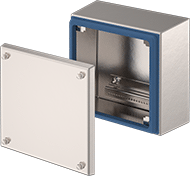

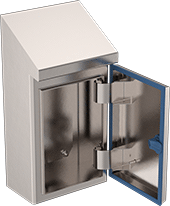

Sanitary Enclosures

|

Lift-Off Cover |

|

Hinged Cover |

Best for safeguarding wiring and electrical components in food, pharmaceutical, and other plants that require frequent washdowns. All of these enclosures are made of stainless steel to stand up to harsh cleaners and sanitizers. Their hygienic design minimizes spots where food and debris can collect, while the sloped roof drains water to prevent pooling and bacteria growth. Inside, a gasket blocks out water and dust to keep contents dry and contaminant-free. The gasket is FDA-compliant for direct contact with food and bright blue, so it's easy to spot if a piece ever breaks off and falls into your line. To leave space for cleaning behind these enclosures, mount them with a standoff to offset them from the wall.

Lift-Off Cover—The removable, screw-secured cover is best for full access during setup or service, but not for frequent entry.

Hinged Cover—The cover swings open for fast, frequent access and remains attached to prevent drops or loss.

Corrosion-Resistant 304 Stainless Steel—Won't corrode from frequent washdowns and can stand up to most cleaners, detergents, and oil. They are not, however, as dent or scratch resistant as steel.

Electrical Enclosures | Standoffs | Replacement Keys | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Dp. | Cover Closure Method | With Knockouts | Enclosure Rating | Food Industry Std. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lift-Off Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 7" | 3" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N24 | 0000000 | 97509A101 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 7" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N25 | 000000 | 97509A101 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 9" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N26 | 000000 | 97509A101 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13" | 9" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N27 | 000000 | 97509A101 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17" | 9" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N28 | 000000 | 97509A101 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17" | 13" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N29 | 000000 | 97509A101 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hinged Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 1/2" | 17" | 6" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N11 | 00000000 | 97509A101 | 00000 | 4724N31 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 22" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N12 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 30" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N14 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20" | 26" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N13 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 24" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N21 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 30" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N15 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 37" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N22 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 39" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N23 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 22" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N16 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 32" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N17 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 48" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N18 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 56" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 4724N19 | 00000000 | 97509A101 | 00000 | 4724N31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Push-Button Enclosures

|

Raised Mount |

|

Raised Mount with Overhanging Roof |

|

Recessed Mount |

Protect control switches, emergency stops, and indicating lights in food, pharmaceutical, and other plants that require frequent washdowns. Made of stainless steel, these enclosures stand up to harsh cleaners and sanitizers. Their hygienic design minimizes spots where food and debris can collect, while a gasket blocks out water and dust to keep contents dry and contaminant-free. The gasket in the FDA-compliant enclosures is safe for direct contact with food. It’s also bright blue, so it's easy to spot if a piece ever breaks off and falls into your line. Use plugs to seal unused mounting holes.

Raised Mount—A standoff or offset bracket creates space between the enclosure and the mounting surface for easy cleaning.

Raised Mount with Overhanging Roof—The roof is sloped, letting water drain quickly to prevent pooling that may lead to bacteria growth. The standoff creates space between the enclosure and the mounting surface for easy cleaning.

Recessed Mount—Install directly into mounting surfaces and sit flush to maximize space and minimize cleaning areas.

Lift-Off Cover—The removable, screw-secured cover is best for full access during setup or service, but not for frequent entry.

Super-Corrosion-Resistant 316L Stainless Steel—Our most corrosion resistant metal enclosures, these hold up in just about any environment. They won’t degrade or become pitted when exposed to salt water or harsh chemicals like bleach, chlorine, and acids. All are harder than aluminum to resist cracking, but not as dent or scratch resistant as steel.

Electrical Enclosures | Plugs | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of | For 22 mm Push Buttons | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Holes | Columns | Rows | Wd. | Ht. | Dp. | Material | Cover Closure Method | Enclosure Rating | Food Industry Std. | External Mount Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Raised Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lift-Off Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1 | 1 | 4" | 4" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | — | Bracket | 8105N133 | 0000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1 | 1 | 4" | 4" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 8105N122 | 000000 | 7805N111 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1 | 2 | 4" | 6" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | — | Bracket | 8105N135 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1 | 2 | 4" | 6" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 8105N124 | 000000 | 7805N111 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1 | 3 | 4" | 8" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 8105N126 | 000000 | 7805N111 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Raised Mount with Overhanging Roof | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lift-Off Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1 | 1 | 4 1/2" | 6" | 4 1/2" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 8105N155 | 000000 | 7805N111 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1 | 3 | 4 1/2" | 10" | 4 1/2" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 8105N159 | 000000 | 7805N111 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Recessed Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lift-Off Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3 | 1 | 11" | 8 1/2" | 3 1/2" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP66 | FDA Compliant 21 CFR 177.2600 | Mounting Hole | 8105N175 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Threaded Plugs for Enclosures

|

|

Super smooth with round edges that prevent bacteria buildup, these plugs are FDA compliant for food processing areas. Screw them in unused threaded holes for a more secure hold than clamp-on and snap-in plugs. These plugs include a seal that locks out moisture and dust to keep your electrical components dry and contaminant-free. Twist them in place from the outside of the enclosure and then tighten with a hex key from the inside.

Super-Corrosion-Resistant 316L Stainless Steel—Superior to 304 stainless steel, these plugs won’t pit or weaken when exposed to harsh chemicals, including bleach and salt water.

Thread Size | Head Dia., mm | For Enclosure Rating | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Super-Corrosion-Resistant 316L Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 19.7 | IP66 | 7805N111 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||