Replaceable Carbide-Insert End Mills for Manual Milling Machines

Use these tools with low-horsepower, manual milling machines. They have clamps for holding inserts that do not have a mounting hole. Replaceable carbide-insert end mills reduce waste and cost in high-volume jobs—when the cutting edges dull, replace the carbide inserts instead of the entire tool. End mills have a square cut style for milling square slots, pockets, and edges. All are noncenter-cutting for operations where the sides of the teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

R8-shank end mills have internal threads on the tapered end for connecting to a drawbar.

Carbide inserts have a wear-resistant titanium-nitride (TiN) coating.

Shank Thread | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mill Dia. | Gender | Size | Overall Lg. | Cut Style | Material | Number of Inserts Required | End Mill Type | Each | |

R8 Taper Shank | |||||||||

| 1" | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 1 | Noncenter Cutting | 0000000 | 0000000 |

| 1 1/4" | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 2 | Noncenter Cutting | 0000000 | 000000 |

| 1 1/2" | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 1 5/8" | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 1 3/4" | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 2" | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 2 1/2" | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 5 | Noncenter Cutting | 0000000 | 000000 |

| 3" | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 5 | Noncenter Cutting | 0000000 | 000000 |

| Tip Radius | Insert Code | Insert Size | Thick. | For Use On | Each | |

Titanium Nitride (TiN) Coated | ||||||

|---|---|---|---|---|---|---|

| 1/64" | TPG-321 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

| 1/32" | TPG-322 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

| 3/64" | TPG-323 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

| 1/16" | TPG-324 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

| Tip Radius | Insert Code | Insert Size | Thick. | For Use On | Pkg. Qty. | Pkg. | |

Titanium Nitride (TiN) Coated | |||||||

|---|---|---|---|---|---|---|---|

| 1/64" | TPG-321 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 10 | 00000000 | 000000 |

| 1/32" | TPG-322 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 10 | 00000000 | 00000 |

| 3/64" | TPG-323 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 10 | 0000000 | 00000 |

| 1/16" | TPG-324 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 10 | 00000000 | 00000 |

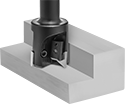

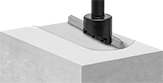

Fly Cutters

Shave shallow layers of material off your workpiece to create a smooth even finish. These fly cutters hold a lathe tool (sold separately) and run on your milling machine. Compared to end mills, these make a wider cut per pass. They also generate less heat, so you can run them at higher speeds. In the long run, these cutters will save you the cost of replacing entire end mills once they dull—you can either sharpen your worn lathe tool or just replace that one part.

Shank Thread | For Tool Bit Shank | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mill Dia. | Gender | Size | Overall Lg. | Wd. | Shape | Ht. | Head Dia. | Material | Heat Treatment | Each | |

R8 Taper Shank | |||||||||||

| 2 1/2" | Female | 7/16"-20 | 5 3/4" | 5/16" | Square | 5/16" | 2 1/2" | Black-Oxide Steel | Hardened | 0000000 | 000000 |

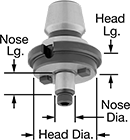

Boring Tool Holders for Milling Machines

Instead of widening a hole using a lathe, which turns the workpiece while the cutting tool stays still, use these holders to turn your boring bar in a milling machine and keep the workpiece stationary. They’re good for creating holes that are too large to drill or a diameter you don’t have a drill bit for. To help you bore holes to precise diameters, these holders have an adjustment dial with fine increments. Mount them in your milling machine using their shank. They’re also known as boring heads.

Shank | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tool Bit Shank Diameter | Length | Head Diameter | Offset Travel | Vertical Hole Spacing | Overall Length | Material | Features | Each | |

Holder with R8 Taper Shank | |||||||||

| 3/8" | 4" | 2" | 0.75" | 0.625" | 6 7/16" | Steel | Adjustment Dial | 00000000 | 0000000 |

| 1/2" | 4" | 2 1/2" | 0.75" | 0.75" | 7 3/16" | Steel | Adjustment Dial | 00000000 | 000000 |

| 5/8" | 4" | 2 1/2" | 0.75" | 0.75" | 7 3/16" | Steel | Adjustment Dial | 00000000 | 000000 |

| 3/4" | 4" | 3" | 1.25" | 0.938" | 7 1/2" | Steel | Adjustment Dial | 00000000 | 000000 |

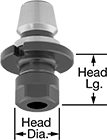

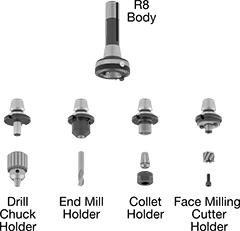

Quick-Change Tool Holders for Milling Machines

After installing the R8 body in the milling machine spindle, tool holders can be switched out in seconds. To remove a tool holder, depress the brass locking button and rotate the collar on the R8 body. When a new tool holder is inserted, a spring-loaded pin snaps the collar back into the locked position.

R8 Taper Shank Thread | ||||||

|---|---|---|---|---|---|---|

| TIR (Total Indicated Runout) Accuracy | Gender | Size | Spindle Overhang | Material | Each | |

| 0.0005" | Female | 7/16"-20 | 1 1/8" | Steel | 0000000 | 000000000 |

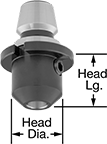

Head | For End Mill | ||||||

|---|---|---|---|---|---|---|---|

| Lg. | Dia. | Number of Milling Ends | Shank Type | Shank Dia. | Material | Each | |

| 1 3/8" | 1/2" | 1 | Straight | 1/8" | Steel | 0000000 | 0000000 |

| 1 3/8" | 11/16" | 1 | Straight | 3/16" | Steel | 0000000 | 000000 |

| 1 3/8" | 11/16" | 1 | Straight | 1/4" | Steel | 0000000 | 000000 |

| 1 3/8" | 1 3/16" | 1 | Straight | 3/8" | Steel | 0000000 | 000000 |

| 1 3/8" | 1 3/8" | 1 | Straight | 1/2" | Steel | 0000000 | 000000 |

| 1 5/8" | 1 9/16" | 1 | Straight | 5/8" | Steel | 0000000 | 000000 |

| 2 3/16" | 1 13/16" | 1 | Straight | 3/4" | Steel | 0000000 | 000000 |

| 2 15/16" | 2" | 1 | Straight | 1" | Steel | 0000000 | 000000 |

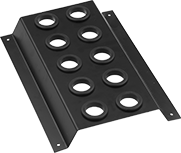

Overall | ||||||||

|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | For Number of Tools | Number of Mounting Holes | Mounting Hole Dia. | Material | Each | |

| 1 1/2" | 8 3/4" | 12 1/4" | 10 | 4 | 3/16" | Steel | 0000000 | 0000000 |