About Plastic and Rubber Tubing

More

About Hose

More

Low-Pressure Chemical Hose

- Temperature Range: -25° to 150° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: Polyethylene with EPDM Rubber Cover

- Color: Green with Light Green Stripe

- Compatible Hose Fittings: Cam-and-Groove.

Per Ft. | ||||||

|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Continuous Lg., ft. | 1-49 | 50-Up | |

150 psi @ 72° F Max. Pressure | ||||||

| 1/2" | 1" | 6" | 50 | 00000000 | 000000 | 000000 |

| 3/4" | 1 1/4" | 7" | 50 | 00000000 | 00000 | 00000 |

| 1" | 1 1/2" | 8" | 50 | 00000000 | 00000 | 00000 |

| 1 1/4" | 1 3/4" | 9" | 50 | 00000000 | 00000 | 00000 |

| 1 1/2" | 2 1/16" | 10" | 50 | 00000000 | 00000 | 00000 |

| 2" | 2 5/8" | 12" | 50 | 00000000 | 00000 | 00000 |

| 3" | 3 5/8" | 18" | 50 | 00000000 | 00000 | 00000 |

| 4" | 4 11/16" | 24" | 50 | 00000000 | 00000 | 00000 |

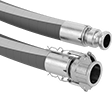

Low-Pressure Chemical Hose with Cam-and-Groove Socket and Plug

- Temperature Range: -25° to 150° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: Polyethylene with EPDM Rubber Cover

- Color: Green with Light Green Stripe

To connect fittings, insert the plug into the socket and push the levers down. Aluminum fittings are lightweight and have good corrosion resistance; 316 stainless steel fittings have excellent corrosion resistance.

| Coupling Size | ID | OD | Bend Radius | 5 ft. | 10 ft. | 12 ft. | 15 ft. | 20 ft. | 25 ft. | 50 ft. | |

Aluminum Cam-and-Groove Female Socket × Aluminum Cam-and-Groove Male Plug | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

150 psi @ 72° F Max. Pressure | |||||||||||

| 1/2 × 1/2 | 1/2" | 1" | 6" | 0000000 | |||||||

| 1 × 1 | 1" | 1 1/2" | 8" | 0000000 | |||||||

| 1 1/4 × 1 1/4 | 1 1/4" | 1 3/4" | 9" | 0000000 | |||||||

| 1 1/2 × 1 1/2 | 1 1/2" | 2 1/16" | 10" | 0000000 | |||||||

| 2 × 2 | 2" | 2 5/8" | 12" | 0000000 | |||||||

| 3 × 3 | 3" | 3 5/8" | 18" | 0000000 | |||||||

316 Stainless Steel Cam-and-Groove Female Socket × 316 Stainless Steel Cam-and-Groove Male Plug | |||||||||||

150 psi @ 72° F Max. Pressure | |||||||||||

| 1/2 × 1/2 | 1/2" | 1" | 6" | 0000000 | |||||||

| 3/4 × 3/4 | 3/4" | 1 1/4" | 7" | 0000000 | |||||||

| 1 × 1 | 1" | 1 1/2" | 8" | 0000000 | |||||||

| 1 1/4 × 1 1/4 | 1 1/4" | 1 3/4" | 9" | 0000000 | |||||||

| 1 1/2 × 1 1/2 | 1 1/2" | 2 1/16" | 10" | 0000000 | |||||||

| 2 × 2 | 2" | 2 5/8" | 12" | 0000000 | |||||||

| 3 × 3 | 3" | 3 5/8" | 18" | 0000000 | |||||||

| 4 × 4 | 4" | 4 3/4" | 24" | 0000000 | |||||||

Flexible Low-Pressure Chemical Hose with Cam-and-Groove Socket and Plug

- Temperature Range: -40° F to 220° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: EPDM Rubber

- Color: Purple with Yellow Stripe

You don’t need a lot of force to bend this hose. The extra flexibility makes it good for offset connections and tight spaces. To connect fittings, insert the plug into the socket and push the levers down.

Flexible Low-Pressure Chemical Hose with Threaded Fittings

- Temperature Range: -40° to 220° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: EPDM Rubber

- Color: Purple with Yellow Stripe

You don’t need a lot of force to bend this hose. The extra flexibility makes it good for offset connections and tight spaces.

Flexible Low-Pressure Chemical Hose

- Temperature Range: -40° to 220° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: EPDM Rubber

- Color: Purple with Yellow Stripe

- Compatible Hose Fittings: Barbed or Cam-and-Groove.

You don’t need a lot of force to bend this hose. The extra flexibility makes it good for offset connections and tight spaces.

Crush-Resistant Low-Pressure Chemical Hose

- Temperature Range: -40° to 180° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: Polyethylene with EPDM Rubber Cover

- Color: Green with Red Stripe

- Compatible Hose Fittings: Cam-and-Groove.

Step on this hose and it springs back to its original shape. Multiple layers of polyethylene plus plastic spiral reinforcement gives it excellent crush and kink resistance.

Crush-Resistant Low-Pressure Chemical

Hose with Cam-and-Groove Socket and Plug

- Temperature Range: -40° to 180° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: Polyethylene with EPDM Rubber Cover

- Color: Green with Red Stripe

Step on this hose and it springs back to its original shape. Multiple layers of polyethylene plus plastic spiral reinforcement gives it excellent crush and kink resistance. To connect fittings, insert the plug into the socket and push the levers down.

| Coupling Size | ID | OD | Bend Radius | 5 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | 50 ft. | |

304 Stainless Steel Cam-and-Groove Female Socket × 304 Stainless Steel Cam-and-Groove Male Plug | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

200 psi @ 72° F Max. Pressure | ||||||||||

| 3/4 × 3/4 | 3/4" | 1 3/16" | 4" | 0000000 | ||||||

| 1 × 1 | 1" | 1 1/2" | 4" | 0000000 | ||||||

| 1 1/2 × 1 1/2 | 1 1/2" | 2" | 5" | 0000000 | ||||||

| 2 × 2 | 2" | 2 3/4" | 8" | 0000000 | ||||||

| 3 × 3 | 3" | 3 5/8" | 10" | 0000000 | ||||||

Wear-Resistant Low-Pressure Chemical Hose

- Temperature Range: -40° to 160° F

- Maximum Vacuum: 28" of Hg @ 72° F

- Material: UHMW Polyethylene with EPDM Rubber Cover

- Color: Green with Purple Stripe

- Compatible Hose Fittings: Cam-and-Groove.

Expose this UHMW (ultra-high molecular weight) polyethylene hose to harsh physical conditions without worrying about it deteriorating or becoming brittle.

Per Ft. | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Continuous Lg., ft. | 1-49 | 50-Up | |

| 3/4" | 1 3/16" | 4" | 200 psi @ 72° F | 50 | 0000000 | 000000 | 000000 |

| 1" | 1 9/16" | 5 1/2" | 200 psi @ 72° F | 50 | 0000000 | 00000 | 00000 |

| 1 1/4" | 1 7/8" | 6" | 200 psi @ 72° F | 50 | 0000000 | 00000 | 00000 |

| 1 1/2" | 2 1/8" | 7 1/2" | 200 psi @ 72° F | 50 | 0000000 | 00000 | 00000 |

| 2" | 2 5/8" | 8" | 200 psi @ 72° F | 50 | 0000000 | 00000 | 00000 |

| 2 1/2" | 3 1/8" | 8" | 200 psi @ 72° F | 50 | 0000000 | 00000 | 00000 |

| 3" | 3 5/8" | 9" | 200 psi @ 72° F | 50 | 0000000 | 00000 | 00000 |

| 4" | 4 11/16" | 15" | 150 psi @ 72° F | 50 | 0000000 | 00000 | 00000 |

Wear-Resistant Low-Pressure Chemical

Hose with Cam-and-Groove Socket and Plug

- Temperature Range: -40° to 160° F

- Maximum Vacuum: 28" of Hg @ 72° F

- Material: UHMW Polyethylene with EPDM Rubber Cover

- Color: Green with Purple Stripe

Expose this UHMW (ultra-high molecular weight) polyethylene hose to harsh physical conditions without worrying about it deteriorating or becoming brittle. To connect fittings, insert the plug into the socket and push the levers down.

High-Temperature Medium-Pressure Chemical Hose

- Temperature Range: -40° to 350° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material:

1/2" and 3/4" ID Hose: PTFE with EPDM Rubber Cover

All Other Hose: FEP with EPDM Rubber Cover - Color: Green with Yellow Stripe

- Compatible Hose Fittings: Barbed

This hose can stand up to chemicals at high temperatures.

Per Ft. | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Continuous Lg., ft. | 1-49 | 50-Up | |

| 1/2" | 15/16" | 2 5/8" | 350 psi @ 72° F | 50 | 000000000 | 000000 | 000000 |

| 3/4" | 1 1/4" | 4 1/8" | 350 psi @ 72° F | 50 | 000000000 | 00000 | 00000 |

| 1" | 1 9/16" | 5 3/4" | 450 psi @ 72° F | 50 | 000000000 | 00000 | 00000 |

| 1 1/4" | 1 3/4" | 8 1/2" | 375 psi @ 72° F | 50 | 000000000 | 00000 | 00000 |

| 1 1/2" | 2 1/8" | 10 1/2" | 350 psi @ 72° F | 50 | 000000000 | 00000 | 00000 |

| 2" | 2 11/16" | 13" | 300 psi @ 72° F | 50 | 000000000 | 000000 | 000000 |

| 3" | 3 7/8" | 21" | 250 psi @ 72° F | 50 | 000000000 | 000000 | 000000 |

| 4" | 5" | 39" | 175 psi @ 72° F | 50 | 000000000 | 000000 | 000000 |

High-Temperature Medium-Pressure Chemical Hose with Fittings

- Temperature Range: -40° to 350° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 1/2" and 3/4" ID hose is PTFE with EPDM Rubber Cover; 1" and 2" ID hose is FEP with EPDM Rubber Cover.

- Color: Green with Yellow Stripe

This hose can stand up to chemicals at high temperatures. 316 stainless steel fittings have excellent corrosion resistance; steel fittings have excellent strength.

| Pipe Size | ID | OD | Bend Radius | Max. Pressure | 1 ft. | 2 ft. | 3 ft. | 4 ft. | 5 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | 50 ft. | |

Steel Threaded NPT Male × Steel Threaded NPT Male | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 × 1/2 | 1/2" | 15/16" | 2 5/8" | 350 psi @ 72° F | 00000000 | ||||||||||

| 3/4 × 3/4 | 3/4" | 1 1/4" | 4 1/8" | 350 psi @ 72° F | 00000000 | ||||||||||

| 1 × 1 | 1" | 1 9/16" | 5 3/4" | 450 psi @ 72° F | 00000000 | ||||||||||

| 2 × 2 | 2" | 2 11/16" | 13" | 300 psi @ 72° F | 000000000 | ||||||||||

316 Stainless Steel Threaded NPT Male × 316 Stainless Steel Threaded NPT Male | |||||||||||||||

| 1/2 × 1/2 | 1/2" | 15/16" | 2 5/8" | 350 psi @ 72° F | 00000000 | ||||||||||

| 3/4 × 3/4 | 3/4" | 1 1/4" | 4 1/8" | 350 psi @ 72° F | 00000000 | ||||||||||

| 1 × 1 | 1" | 1 9/16" | 5 3/4" | 450 psi @ 72° F | 00000000 | ||||||||||

| 2 × 2 | 2" | 2 11/16" | 13" | 300 psi @ 72° F | 00000000 | ||||||||||

Water Hose with Brass Male and Female Threaded Fittings

- Temperature Range: 10° to 150° F

- Material: EPDM Rubber

- Color: Black or Red

- Female Fitting Swivels Until Tightened

Transfer and spray water at low pressure. This hose also works with mild water-based chemicals, such as cleaning products. Made of EPDM rubber, it resists cracking when exposed to ozone or UV light. It’s reinforced with yarn for strength.

This hose comes with brass fittings, which are softer than stainless steel fittings for easier threading. However, they’re less corrosion resistant. The female fitting swivels until tightened, so you can thread it without moving and twisting the entire hose.

Diesel Exhaust Fluid Transfer Hose with Cam-and-Groove Fittings

- Temperature Range: -40° to 210° F

- Maximum Vacuum: 29" @ 72° F

- Material: EPDM Rubber with EPDM Rubber Cover

- Color: Blue

Maintain the purity of diesel exhaust fluid (DEF) as you move it from tanker trucks to storage tanks. Made of peroxide-cured EPDM with stainless steel fittings, this hose won’t leach contaminants into your line. The fittings also resist corroding from harsh cleaning chemicals. This hose is flexible, so it’s easy to maneuver and coil around reels. Reinforced with yarn and steel, it holds its shape and resists kinking.

The fittings make it easy to connect and disconnect the line. Insert the plug into the socket and push the levers down.

Diesel Exhaust Fluid Dispensing Hose with Threaded Fittings

Avoid contamination as you supply a selective catalytic reduction (SCR) system with diesel exhaust fluid (DEF). Made of peroxide-cured EPDM with stainless steel fittings, this hose won’t leach contaminants into DEF. The fittings also resist corroding from mild chemicals and water. This hose is flexible, so it’s easy to maneuver and coil around reels. Reinforced with yarn, it holds its shape during use and resists kinking. A static control wire runs through the hose and connects to the fittings at both ends to safely discharge static electricity.

Thread one end into your pump and the other into a nozzle or swivel (both sold separately). Threaded swivels install between your hose and your nozzle to keep your line from twisting, kinking, and wearing prematurely. Thread sealants (sold separately) fill the small gaps between threads to prevent leaks. None of these accessories will contaminate DEF.

- Temperature Range: -40° to 140° F

- Material: EPDM Rubber with EPDM Rubber Cover

- Color: Black

| Pipe Size | ID | OD | Bend Radius | Max. Pressure | 5 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | |

304 Stainless Steel Threaded NPT Male × 304 Stainless Steel Threaded NPT Male | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3/4 × 3/4 | 3/4" | 1 1/8" | 7 1/2" | 250 psi @ 72° F | 00000000 | |||||

304 Stainless Steel Threaded BSPP Male × 304 Stainless Steel Threaded BSPP Male | ||||||||||

| 3/4 × 3/4 | 3/4" | 1 1/8" | 7 1/2" | 250 psi @ 72° F | 00000000 | |||||

Nozzles | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Spout | Threaded Swivels | Thread Sealants | ||||||||||||||

| Max. Flow Rate, gpm | Pipe Size | Connection | Max. Pressure | Temp. Range, °F | OD | Lg. | Material | Spout Material | Scuff Guard Color | Each | Each | Container Size | Each | |||

| 15 | 3/4 | Threaded NPTF Female | 50 psi @ 72° F | -10° to 150° | 3/4" | 7" | Anodized Aluminum | Stainless Steel | Blue | 0000000 | 0000000 | 00000000 | 000000 | 4 fl. oz. | 0000000 | 000000 |

| 15 | 3/4 | Threaded BSPP Female | 50 psi @ 72° F | -10° to 150° | 3/4" | 7" | Anodized Aluminum | Stainless Steel | Blue | 0000000 | 000000 | 00000000 | 00000 | __ | 000000 | 00 |

Large-Diameter Soft Rubber Tubing for Chemicals

- Semi-Flexible

- Soft (Durometer 55A)

- Temperature Range: -90° to 290° F

With a diameter of 2" or larger, this EPDM tubing has the girth to handle high volumes of acids and other harsh substances. Tubing connects to fittings with a clamp (sold separately). It is opaque, so you cannot see inside the line to monitor flow. It is semi-flexible, so it is good for gradual bends.