Filter by

For Use On

Density

Approximate Coverage Volume

RoHS

Flammability Rating

Heat Flow Rate @ Temperature

Approximate Coverage @ Thickness

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Spray Foam Insulation

Nonreusable

Spray Foam Insulation | Dispensing Guns | Cleaners for Dispensing Guns | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Net Wt., oz. | Type | Approx. Coverage @ Thk. | Begins to Harden, hr. | Reaches Full Strength, hr. | Heat Flow Rate @ Temp. | Density, lb/ft³ | Color | Temp. Range, ° F | Includes | Flammability Rating | Specs. Met | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Walls and Ceilings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | Can | 16 ft² @ 1/2" | 1 | 24 | 0.2 BTU/hr @ 72° F | 1.1 | Black | -200 to 240 | One Dispensing Tube | ASTM E84 25/50 for Flame and Smoke | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | Can | 16 ft² @ 1/2" | 1 | 24 | 0.2 BTU/hr @ 72° F | 1.2 | Beige | -200 to 240 | One Dispensing Tube | ASTM E84 25/50 for Flame and Smoke | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | Can | 32 ft² @ 1/2" | 1 | 24 | 0.2 BTU/hr @ 72° F | 1.2 | Beige | -200 to 240 | One Dispensing Tube | ASTM E84 25/50 for Flame and Smoke | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | Can | 36 ft² @ 1/2" | 1 | 24 | 0.2 BTU/hr @ 72° F | 1 | Black | -200 to 240 | — | ASTM E84 25/50 for Flame and Smoke | — | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Windows and Doors | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | Can | 32 ft² @ 1/2" | 1 | 24 | 0.2 BTU/hr @ 72° F | 1.2 | Beige | -200 to 240 | One Dispensing Tube | ASTM E84 25/50 for Flame and Smoke | AAMA 812-04 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Expanding Foam

For Box | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Expansion, cu. in. | Lg. | Wd. | Ht. | Compressed Lg. | Compressed Wd. | Clarity | Color | Material | Cover Material | Begins to Set, sec. | Each | ||

| 180 | 8" | 8" | 8" | 18" | 15" | Opaque | White | Polyurethane Foam | Polyethylene | 60 | 0000000 | 00000 | |

| 390 | 10" | 10" | 10" | 18" | 18" | Opaque | White | Polyurethane Foam | Polyethylene | 60 | 0000000 | 0000 | |

| 510 | 12" | 12" | 12" | 24" | 18" | Opaque | White | Polyurethane Foam | Polyethylene | 60 | 0000000 | 00000 | |

| 630 | 14" | 14" | 14" | 24" | 18" | Opaque | White | Polyurethane Foam | Polyethylene | 60 | 0000000 | 00000 | |

| 680 | 14" | 14" | 14" | 22" | 20" | Opaque | White | Polyurethane Foam | Polyethylene | 60 | 00000000 | 00000 | |

| 755 | 18" | 12" | 12" | 27" | 22" | Opaque | White | Polyurethane Foam | Polyethylene | 60 | 0000000 | 00000 | |

| 965 | 16" | 16" | 16" | 27" | 25" | Opaque | White | Polyurethane Foam | Polyethylene | 60 | 0000000 | 00000 | |

Foam Casting Compounds

Foam Expansion | Density, lb/ft³ | Time to Harden, min. | Time to Cure, min. | Time to Demold, min. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polyurethane Foam | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

White | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flexible—Not Machinable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4X | 12 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 3 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4X | 12 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8X | 8 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8X | 8 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15X | 4 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15X | 4 | 3 | 25 | 25 | 80 | 125 | Not Rated | White | Yes | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Beige | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rigid—Machinable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2X | 20 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 16 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7X | 12 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 4 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7X | 12 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 16 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19X | 4 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 4 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19X | 4 | 3 | 15 | 15 | 75 | 85 | Not Rated | Beige | Yes | 16 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gap-Filling Spray Foam Insulation

Nonreusable

Spray Foam Insulation | Dispensing Guns | Cleaners for Dispensing Guns | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Net Wt., lb. | Type | Approx. Coverage Volume, cu. ft. | Begins to Harden, min. | Reaches Full Strength, hr. | Heat Flow Rate @ Temp. | Density, lb/ft³ | Color | Temp. Range, ° F | Includes | Flammability Rating | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Walls and Ceilings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | Can | 1.2 | 5 | 1 | 0.16 BTU/hr @ 75° F | 2.11 | Beige | -200 to 240 | Two Cans of Foam with Two Cone Spray Nozzles | — | 0000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | Cylinder | 12.3 | 5 | 24 | 0.2 BTU/hr @ 75° F | 1.3 | Beige | -200 to 240 | One Cylinder with Two Trigger-Style Wands | ASTM E84 5/20 for Flame and Smoke | 0000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

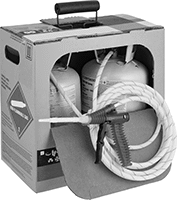

| 30 | Cylinder | 12 | 2 | 24 | 0.16 BTU/hr @ 75° F | 2.5 | Beige | -200 to 240 | Two Cylinders with a Trigger-Style Gun and Ten Cone Spray Nozzles | ASTM E84 0/45 for Flame and Smoke | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reusable

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Net Wt., lb. | Type | Approx. Coverage Volume, cu. ft. | Begins to Harden, min. | Reaches Full Strength, hr. | Heat Flow Rate @ Temp. | Density, lb/ft³ | Color | Temp. Range, ° F | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Walls and Ceilings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | Cylinder | 5 | 5 | 1 | 0.16 BTU/hr @ 75° F | 3.1 | Beige | -200 to 200 | Two Cylinders with a Trigger-Style Gun and Ten Snap-Tip Nozzles | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | Cylinder | 9.6 | 5 | 1 | 0.16 BTU/hr @ 75° F | 3.1 | Beige | -200 to 200 | Two Cylinders with a Trigger-Style Gun and Ten Snap-Tip Nozzles | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fireblock Spray Foam Insulation

Nonreusable

Spray Foam Insulation | Dispensing Guns | Cleaners for Dispensing Guns | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Net Wt., oz. | Type | Approx. Coverage @ Thk. | Begins to Harden, min. | Reaches Full Strength, hr. | Heat Flow Rate @ Temp. | Density, lb/ft³ | Color | Temp. Range, ° F | Includes | Flammability Rating | Specs. Met | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Walls and Ceilings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | Can | 16 ft² @ 1/2" | 5 | 24 | 0.2 BTU/hr @ 72° F | 1.1 | Orange | -200 to 240 | One Dispensing Tube | ASTM E84 25/50 for Flame and Smoke | UL 2818 | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | Can | 36 ft² @ 1/2" | 5 | 24 | 0.2 BTU/hr @ 72° F | 1 | Orange | -200 to 240 | — | ASTM E84 25/50 for Flame and Smoke | UL 2818 | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Cure Spray Foam Insulation

Nonreusable

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Net Wt., oz. | Type | Approx. Coverage Volume, cu. ft. | Begins to Harden, min. | Heat Flow Rate @ Temp. | Density, lb/ft³ | Color | Temp. Range, ° F | Includes | Flammability Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Walls and Ceilings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | Can | 0.3 | 3 | Not Rated | 1.9 | Blue | -40 to 175 | Two Dispensing Tubes | ASTM E84 25/210 for Flame and Smoke | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealing Gasket Tape for Large Gaps and Voids

Wd. | Lg., ft. | Compressed Thk. | Expanded Thk. | Material | Adhesive Type | Temp. Range, ° F | Cell Type | Tensile Strength | Adhesion to Steel | Color | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 26 | 5/32" | 5/8" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 000000 | |

| 1/2" | 32 | 3/32" | 3/8" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 0000 | |

| 1/2" | 32 | 1/8" | 1/2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 1" | 6 | 3/4" | 3" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 1" | 13 | 5/16" | 1 1/4" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 1" | 13 | 3/8" | 1 1/2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 1" | 13 | 1/2" | 2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 1" | 19 | 3/16" | 3/4" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 1" | 19 | 1/4" | 1" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 1" | 26 | 5/32" | 5/8" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 1" | 32 | 3/32" | 3/8" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 1" | 32 | 1/8" | 1/2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 6 | 3/4" | 3" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 13 | 5/16" | 1 1/4" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 13 | 3/8" | 1 1/2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 13 | 7/16" | 1 3/4" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 13 | 1/2" | 2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 19 | 3/16" | 3/4" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 19 | 1/4" | 1" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 26 | 5/32" | 5/8" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 32 | 3/32" | 3/8" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 2" | 32 | 1/8" | 1/2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 3" | 6 | 1/2" | 2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 3" | 6 | 3/4" | 3" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 3" | 13 | 3/8" | 1 1/2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 3" | 19 | 1/8" | 1/2" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 3" | 19 | 1/4" | 1" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 | |

| 3" | 32 | 3/32" | 3/8" | Polyurethane Foam | Acrylic | -40 to 185 | Open | Not Rated | Not Rated | Black | 0000000 | 00000 |

Flame-Retardant Gap-Filling Spray Foam Insulation

Reusable

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Net Wt., lb. | Type | Approx. Coverage Volume, cu. ft. | Begins to Harden, min. | Reaches Full Strength, hr. | Heat Flow Rate @ Temp. | Density, lb/ft³ | Color | Temp. Range, ° F | Includes | Flammability Rating | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Walls and Ceilings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | Cylinder | 9.7 | 5 | 1 | 0.154 BTU/hr @ 75° F | 1.75 | Beige | -200 to 240 | Two Cylinders with a Trigger-Style Gun and Eight Snap-Tip Nozzles | ASTM E84 10/350 for Flame and Smoke | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | Cylinder | 17 | 5 | 1 | 0.154 BTU/hr @ 75° F | 1.75 | Beige | -200 to 240 | Two Cylinders with a Trigger-Style Gun and Eight Snap-Tip Nozzles | ASTM E84 10/350 for Flame and Smoke | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||