Filter by

Dynamic Combined Load Capacity

Bolt Circle Diameter

Lubrication

Static Combined Load Capacity

Maximum Rotation Speed

Mounting Hole Location

Export Control Classification Number (ECCN)

DFARS Specialty Metals

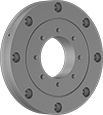

High-Load Face-Mount Crossed-Roller Bearings

Combined Load Cap., lbf | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Dynamic | Static | Max. Rotation Speed, rpm | Lubrication | Temp. Range, ° F | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Combined Radial, Thrust, and Moment Load—Open with Steel Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 52 | 8 | 650 | 540 | 2,400 | Required | 0 to 230 | Lubrication Groove, Two Lubrication Holes | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 70 | 12 | 1,700 | 1,850 | 1,600 | Required | 0 to 230 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 80 | 12 | 1,900 | 2,350 | 1,400 | Required | 0 to 230 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 95 | 15 | 3,850 | 4,650 | 1,100 | Required | 0 to 230 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 120 | 15 | 4,500 | 6,200 | 850 | Required | 0 to 230 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 165 | 22 | 11,400 | 16,100 | 600 | Required | 0 to 230 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 210 | 25 | 16,500 | 24,200 | 500 | Required | 0 to 230 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 115 | 240 | 28 | 18,950 | 31,000 | 400 | Required | 0 to 230 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 160 | 295 | 35 | 23,350 | 38,850 | 350 | Lubricated | 0 to 175 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 210 | 380 | 40 | 35,050 | 63,150 | 260 | Lubricated | 0 to 175 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Combined Radial, Thrust, and Moment Load—Sealed with Steel Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 52 | 8 | 650 | 540 | 1,900 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 70 | 12 | 1,700 | 1,850 | 1,300 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 80 | 12 | 1,900 | 2,350 | 1,100 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 95 | 15 | 3,850 | 4,650 | 900 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 120 | 15 | 4,500 | 6,200 | 650 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 165 | 22 | 11,400 | 16,100 | 450 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 210 | 25 | 16,500 | 24,200 | 400 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 115 | 240 | 28 | 18,950 | 31,000 | 300 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 160 | 295 | 35 | 23,350 | 38,850 | 350 | Lubricated | 0 to 175 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 210 | 380 | 40 | 35,050 | 63,150 | 260 | Lubricated | 0 to 175 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thin-Profile Face-Mount Crossed-Roller Bearings

Combined Load Cap., lbf | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Dynamic | Static | Max. Rotation Speed, rpm | Lubrication | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Combined Radial, Thrust, and Moment Load—Open with Steel Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 43 | 5 | 330 | 310 | 2,800 | Lubricated | 0 to 210 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 53 | 5 | 420 | 480 | 2,050 | Lubricated | 0 to 210 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 63 | 5 | 480 | 610 | 1,600 | Lubricated | 0 to 210 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 73 | 5 | 540 | 780 | 1,300 | Lubricated | 0 to 210 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||