About Exhaust Fans

More

About Calculating the Airflow Required for Air Cleaning

More

About Sound Levels

Measured in decibels (dB), volume ratings indicate how much noise equipment makes. Some common volume levels include a whisper @ 20 dB, a refrigerator @ 40 dB, a conversation @ 60 dB, and a light machine shop @ 90 dB. OSHA recommends hearing protection for exposure to 80 dB and greater.

About Air Compressors

More

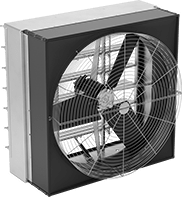

Forced-Air Ventilating Wall-Mount Fans

Improve air quality and manage temperature and moisture levels by forcing fresh air into your space instead of exhausting air out. These fans create positive pressure to push air into an enclosed space, helping create static pressure to quickly ventilate smoke, gas, and other fumes. They’re direct-drive fans, so they have fewer moving parts than belt-drive fans for less maintenance.

For Opening | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage (Current) | Blade Dia. | Airflow, cfm | Motor Speed, rpm | No. of Speeds | Power, hp | Ht. | Wd. | Ht. | Wd. | Dp. | Frame Material | Blade Material | Guard Material | Environmental Rating | Each | |

Three Phase—Hardwire | ||||||||||||||||

Non-Oscillating | ||||||||||||||||

| 190V AC (10.9 A) 208V AC (11.7 A) 240V AC (1.9 A) | 58" | 34,000 | 600 | 1 | 3 | 65 1/2" | 65 1/2" | 65" | 65" | 34" | Polypropylene Plastic | Plastic | 304 Stainless Steel | IP65 | 0000000 | 000000000 |

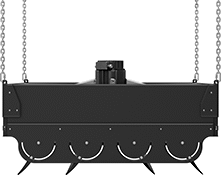

Low-Profile Direct-Drive Ceiling-Mount Fans

Ideal for low-clearance applications where you need headroom, these direct-drive fans are compact and have fewer moving parts than belt-drive fans for less maintenance. The louvers adjust so you can direct airflow in two directions at the same time. They have a polyethylene housing, so they’re durable and resist corrosion.

Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage | Current, A | Blade Dia. | Airflow, cfm | Motor Speed, rpm | No. of Speeds | Power, hp | Ht. | Wd. | Dp. | Housing Material | Blade Material | Environmental Rating | Includes | Each | |

Three Phase—Hardwire | |||||||||||||||

Non-Oscillating | |||||||||||||||

| 190V AC 208V AC 240V AC | 10.9 11.7 10.1 | 58" | 40,100 | 600 | 1 | 3 | 65 1/4" | 65 1/4" | 31" | Polyethylene Plastic | Plastic | IP65 | Mounting Chain Kit | 0000000 | 000000000 |

Direct-Drive Downdraft Roof-Mount Exhaust Fans

Direct-drive fans have fewer moving parts than belt-drive fans for less maintenance. More economical than upblast roof-mount exhaust fans, these draw stagnant and humid air out through your roof and then direct it back toward the roof. All fans have a disconnect switch to turn off the power for servicing.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

Fans | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Mounting Bases | |||||||||||||||

| Blade Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Base Wd. | Wt., lbs. | Max. Ambient Temp., °F | Housing Material | Specifications Met | Each | Each | |||

Open Dripproof Motor Enclosure | ||||||||||||||||

208/230V AC, Three Phase—Hardwire | ||||||||||||||||

| 3 | 19" | 4,500 cfm @ 1/2 in. of H₂O 5,000 cfm @ 0 in. of H₂O | 75 dBA @ 5 ft. | 1,300 | 2 | 38 15/16" | 32 3/4" | 28" | 189 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000000 | 0000000 | 0000000 |

| 3 | 21" | 6,200 cfm @ 1/2 in. of H₂O 6,700 cfm @ 0 in. of H₂O | 82 dBA @ 5 ft. | 1,400 | 5 | 38 15/16" | 32 1/4" | 28" | 201 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

| 3 | 24" | 8,100 cfm @ 1/2 in. of H₂O 9,000 cfm @ 0 in. of H₂O | 73 dBA @ 5 ft. | 925 | 3 | 43 7/16" | 37 1/4" | 33" | 288 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

| 3 | 30" | 10,400 cfm @ 1/2 in. of H₂O 11,500 cfm @ 0 in. of H₂O | 69 dBA @ 5 ft. | 700 | 5 | 52 13/16" | 44" | 40" | 467 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

| 3 | 36" | 11,000 cfm @ 1/2 in. of H₂O 13,500 cfm @ 0 in. of H₂O | 64 dBA @ 5 ft. | 450 | 5 | 63 5/16" | 49 1/2" | 44" | 532 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

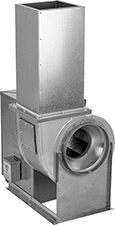

Direct-Drive Exhaust Fans

With fewer moving parts than belt-drive fans, these direct-drive exhaust fans require less maintenance. They have a built-in grease pan to collect waste while cooking. Mount these fans directly to your roof with the attached mounting brackets. They meet UL standards for ventilation in residential, commercial, and institutional kitchens.

| Blade Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | No. of Speeds | Power, hp | Overall Ht. | Base Wd. | Max. Ambient Temp., °F | Housing Material | Blade Material | Features | Specifications Met | Each | |

Open Dripproof Motor Enclosure | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

208V AC, Three Phase—Hardwire | ||||||||||||||

| 16" | 3,000 cfm @ 1/2 in. of H₂O 3,500 cfm @ 0 in. of H₂O | 71 dB @ 5 ft. | 1,650 | Variable | 1 1/2 | 59 3/4" | 32 5/8" | 350° | Steel | Aluminum | Grease Pan | UL 705, UL 762, ULC-S645, ETL Listed | 0000000 | 000000000 |

| 19" | 3,800 cfm @ 1/2 in. of H₂O 4,500 cfm @ 0 in. of H₂O | 76 dB @ 5 ft. | 1,175 | Variable | 1 1/2 | 66 1/8" | 37 1/2" | 350° | Steel | Aluminum | Grease Pan | UL 705, UL 762, ULC-S645, ETL Listed | 0000000 | 00000000 |

| 21" | 5,000 cfm @ 1/2 in. of H₂O 5,500 cfm @ 0 in. of H₂O | 77 dB @ 5 ft. | 1,275 | Variable | 3 | 71 7/8" | 38 1/4" | 350° | Steel | Aluminum | Grease Pan | UL 705, UL 762, ULC-S645, ETL Listed | 0000000 | 00000000 |

| 25" | 5,500 cfm @ 1/2 in. of H₂O 6,500 cfm @ 0 in. of H₂O | 72 dB @ 5 ft. | 900 | Variable | 3 | 80 3/8" | 49 1/4" | 350° | Steel | Steel | Grease Pan | UL 705, UL 762, ULC-S645, ETL Listed | 0000000 | 00000000 |

| 31" | 7,000 cfm @ 1/2 in. of H₂O 8,500 cfm @ 0 in. of H₂O | 72 dB @ 5 ft. | 675 | Variable | 5 | 85 7/8" | 52 1/4" | 350° | Steel | Steel | Grease Pan | UL 705, UL 762, ULC-S645, ETL Listed | 0000000 | 00000000 |

| 37" | 12,000 cfm @ 1/2 in. of H₂O 14,000 cfm @ 0 in. of H₂O | 72 dB @ 5 ft. | 575 | Variable | 7 1/2 | 93 1/4" | 59" | 350° | Steel | Steel | Grease Pan | UL 705, UL 762, ULC-S645, ETL Listed | 0000000 | 00000000 |

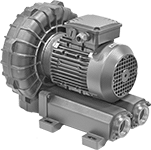

High-Flow Low-Pressure Compressed Air Blowers

Also known as regenerative blowers, use these to produce high-flow compressed air with low pressure or vacuum to operate pump drives, lift tables, and conveying systems. Compressed air blowers are also used for drying, exhausting, and aeration.

Air circulates inside the blower housing to compress air, which generates pressure or vacuum. Single-stage blowers circulate air once and then exhaust. Two-stage blowers circulate air twice and then exhaust, creating higher pressure or vacuum than single-stage blowers with the same horsepower.

Inverter-rated blowers have a motor that can run at slow speeds without overheating, so they can be used with a motor speed control (variable frequency drive).

Blowers | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Pipe Size | Air-Intake Filters | Relief Valves | ||||||||||||||

| Maximum Pressure | Max. Flow Rate @ psi | Vacuum Rating | hp | Full Load Current | Vol. | Lg. | Wd. | Ht. | Temp. Range, °F | Inlet | Outlet | Each | Each | Each | |||

Single Phase, 120/208/230V AC | |||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||

| 1 psi 29 in. of H₂O | 27 cfm @ 0 | 1.9 in. of Hg 27 in. of H₂O | 1/8 | 2.3 A @ 115 V AC 1.2 A @ 208 V AC 1.2 A @ 230 V AC | 57 dBA | 9" | 8" | 9" | 32° to 100° | 1 | 1 | 0000000 | 0000000 | 00000000 | 0000000 | 00000000 | 0000000 |

| 1 psi 39 in. of H₂O | 42 cfm @ 0 | 2.6 in. of Hg 35 in. of H₂O | 1/3 | 3.8 A @ 115 V AC 2.0 A @ 208 V AC 1.9 A @ 230 V AC | 63 dBA | 10" | 9" | 9" | 32° to 100° | 1 | 1 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| 1 psi 52 in. of H₂O | 156 cfm @ 0 | 3.8 in. of Hg 51 in. of H₂O | 2 | 19.7 A @ 115 V AC 10.6 A @ 208 V AC 9.9 A @ 230 V AC | 71 dB | 14" | 13" | 14" | 5° to 100° | 2 | 2 | 0000000 | 00000000 | 000000 | 00 | 0000000 | 000000 |

| 2 psi 42 in. of H₂O | 52 cfm @ 0 | 3.0 in of Hg 40 in. of H₂O | 1/2 | 6.0 A @ 115 V AC 3.2 A @ 208 V AC 3.0 A @ 230 V AC | 68 dBA | 13" | 10" | 10" | 32° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| 2 psi 52 in. of H₂O | 92 cfm @ 0 | 3.5 in. of Hg 48 in. of H₂O | 1 | 9.8 A @ 115 V AC 5.2 A @ 208 V AC 4.9 A @ 230 V AC | 68 dBA | 13" | 11" | 12" | 32° to 100° | 1 1/2 | 1 1/2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| 2 psi 65 in. of H₂O | 127 cfm @ 0 | 4.4 in. of Hg 60 in. of H₂O | 1 1/2 | 17.5 A @ 115 V AC 10.0 A @ 208 V AC 9.0 A @ 230 V AC | 74 dBA | 16" | 13" | 14" | 32° to 100° | 1 1/2 | 1 1/2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

Three Phase, 208/230/460V AC | |||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||

| 2 psi 43 in. of H₂O | 53 cfm @ 0 | 2.9 in. of Hg 40 in. of H₂O | 1/2 | 2.0 A @ 208 V AC 2.0 A @ 230 V AC 1.0 A @ 460 V AC | 68 dBA | 11" | 10" | 10" | 32° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| 2 psi 52 in. of H₂O | 92 cfm @ 0 | 3.5 in. of Hg 48 in. of H₂O | 1 | 3.4 A @ 208 V AC 3.2 A @ 230 V AC 1.6 A @ 460 V AC | 68 dBA | 13" | 11" | 12" | 32° to 100° | 1 1/2 | 1 1/2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| 2 psi 65 in. of H₂O | 127 cfm @ 0 | 4.4 in. of Hg 60 in. of H₂O | 1 1/2 | 5.1 A @ 208 V AC 4.9 A @ 230 V AC 2.5 A @ 460 V AC | 74 dBA | 14" | 13" | 14" | 32° to 100° | 1 1/2 | 1 1/2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

Three Phase, 208/230/460V AC (Inverter Rated) | |||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||

| 1 psi 52 in. of H₂O | 156 cfm @ 0 | 3.8 in. of Hg 51 in. of H₂O | 2 | 5.7 A @ 208 V AC 5.7 A @ 230 V AC 2.8 A @ 460 V AC | 71 dB | 14" | 13" | 14" | 5° to 100° | 2 | 2 | 0000000 | 00000000 | 000000 | 00 | 0000000 | 000000 |

| 2 psi 80 in. of H₂O | 156 cfm @ 0 | 6.6 in. of Hg 89 in. of H₂O | 3 | 8.2 A @ 208 V AC 8.3 A @ 230 V AC 4.1 A @ 460 V AC | 71 dB | 14" | 13" | 14" | 5° to 100° | 2 | 2 | 0000000 | 00000000 | 000000 | 00 | 0000000 | 000000 |

| 3 psi 110 in. of H₂O | 216 cfm @ 0 | 8.1 in. of Hg 110 in. of H₂O | 5 1/2 | 14.6 A @ 208 V AC 15.1 A @ 230 V AC 7.5 A @ 460 V AC | 74 dB | 15" | 15" | 15" | 5° to 100° | 2 | 2 | 0000000 | 00000000 | 000000 | 00 | 0000000 | 000000 |

| 4 psi 105 in. of H₂O | 207 cfm @ 0 | 6.5 in. of Hg 88 in. of H₂O | 5 | 13.0 A @ 208 V AC 12.0 A @ 230 V AC 6.0 A @ 460 V AC | 72 dBA | 19" | 15" | 15" | 32° to 100° | 2 | 2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| 4 psi 110 in. of H₂O | 265 cfm @ 0 | 6.6 in. of Hg 90 in. of H₂O | 6 | 16.0 A @ 208 V AC 15.0 A @ 230 V AC 7.5 A @ 460 V AC | 79 dBA | 17" | 17" | 18" | 32° to 100° | 2 | 2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| 4 psi 110 in. of H₂O | 307 cfm @ 0 | 8.9 in. of Hg 121 in. of H₂O | 7 1/2 | 19.8 A @ 208 V AC 19.5 A @ 230 V AC 9.7 A @ 460 V AC | 75 dBA | 22" | 18" | 19" | 5° to 100° | 3 | 3 | 0000000 | 00000000 | 000000 | 00 | 0000000 | 000000 |

| 5 psi 125 in. of H₂O | 420 cfm @ 0 | 8.1 in. of Hg 110 in. of H₂O | 10 | 35.0 A @ 208 V AC 29.5 A @ 230 V AC 15.0 A @ 460 V AC | 78 dBA | 22" | 18" | 20" | 32° to 100° | 2 1/2 | 2 1/2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

Blowers | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Pipe Size | Relief Valves | |||||||||||||

| Maximum Pressure | Max. Flow Rate @ psi | Vacuum Rating | hp | Full Load Current | Vol. | Lg. | Wd. | Ht. | Temp. Range, °F | Inlet | Outlet | Each | Each | ||

Single Phase, 120/208/230V AC | |||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||

| 3 psi 98 in. of H₂O | 35 cfm @ 0 | 7.2 in. of Hg 97 in. of H₂O | 3/4 | 8.3 A @ 115 V AC 4.1 A @ 208 V AC 4.2 A @ 230 V AC | 64 dB | 14" | 10" | 11" | 5° to 100° | 3/4 | 3/4 | 0000000 | 000000000 | 0000000 | 0000000 |

| 4 psi 120 in. of H₂O | 35 cfm @ 0 | 8.1 in. of Hg 110 in. of H₂O | 1 | 9.4 A @ 115 V AC 5.5 A @ 208 V AC 5.0 A @ 230 V AC | 64 dB | 16" | 10" | 11" | 5° to 100° | 3/4 | 3/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 5 psi 140 in. of H₂O | 65 cfm @ 0 | 11.1 in. of Hg 151 in. of H₂O | 2 | 19.7 A @ 115 V AC 10.6 A @ 208 V AC 9.9 A @ 230 V AC | 72 dB | 15" | 13" | 14" | 5° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 5 psi 141 in. of H₂O | 81 cfm @ 0 | 11.1 in. of Hg 151 in. of H₂O | 3 | 29.4 A @ 115 V AC 16.6 A @ 208 V AC 14.8 A @ 230 V AC | 73 dB | 15" | 14" | 15" | 5° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 5 psi 161 in. of H₂O | 41 cfm @ 0 | 10.3 in. of Hg 140 in. of H₂O | 1 1/2 | 14.6 A @ 115 V AC 7.6 A @ 208 V AC 7.3 A @ 230 V AC | 69 dB | 14" | 11" | 12" | 5° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 0000000 | 000000 |

Three Phase, 208/230/460V AC (Inverter Rated) | |||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||

| 3 psi 98 in. of H₂O | 35 cfm @ 0 | 7.2 in. of Hg 97 in. of H₂O | 3/4 | 2.3 A @ 208 V AC 2.2 A @ 230 V AC 1.3 A @ 460 V AC | 64 dB | 14" | 10" | 11" | 5° to 100° | 3/4 | 3/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 4 psi 120 in. of H₂O | 35 cfm @ 0 | 8.1 in. of Hg 110 in. of H₂O | 1 | 2.9 A @ 208 V AC 2.9 A @ 230 V AC 1.4 A @ 460 V AC | 64 dB | 16" | 10" | 11" | 5° to 100° | 3/4 | 3/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 5 psi 140 in. of H₂O | 65 cfm @ 0 | 11.1 in. of Hg 151 in. of H₂O | 2 | 5.8 A @ 208 V AC 5.2 A @ 230 V AC 2.8 A @ 460 V AC | 72 dBA | 16" | 13" | 14" | 5° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 5 psi 140 in. of H₂O | 147 cfm @ 0 | 11.8 in. of Hg 160 in. of H₂O | 5 1/2 | 14.6 A @ 208 V AC 15.1 A @ 230 V AC 7.5 A @ 460 V AC | 77 dBA | 17" | 18" | 19" | 5° to 100° | 2 | 2 | 0000000 | 00000000 | 0000000 | 000000 |

| 5 psi 141 in. of H₂O | 81 cfm @ 0 | 11.1 in. of Hg 151 in. of H₂O | 3 | 8.3 A @ 208 V AC 7.4 A @ 230 V AC 4.0 A @ 460 V AC | 73 dBA | 16" | 14" | 15" | 5° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 5 psi 161 in. of H₂O | 41 cfm @ 0 | 10.3 in. of Hg 140 in. of H₂O | 1 1/2 | 4.3 A @ 208 V AC 4.3 A @ 230 V AC 2.1 A @ 460 V AC | 69 dB | 14" | 11" | 12" | 5° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 6 psi 191 in. of H₂O | 65 cfm @ 0 | 11.1 in. of Hg 151 in. of H₂O | 3 | 8.2 A @ 208 V AC 8.3 A @ 230 V AC 4.1 A @ 460 V AC | 73 dB | 15" | 13" | 14" | 5° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 7 psi 201 in. of H₂O | 81 cfm @ 0 | 11.1 in. of Hg 151 in. of H₂O | 4 | 10.9 A @ 208 V AC 11.1 A @ 230 V AC 5.5 A @ 460 V AC | 73 dB | 15" | 14" | 15" | 5° to 100° | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 0000000 | 000000 |

| 7 psi 200 in. of H₂O | 177 cfm @ 0 | 13.3 in. of Hg 180 in. of H₂O | 10 | 26.1 A @ 208 V AC 25.0 A @ 230 V AC 12.5 A @ 460 V AC | 78 dBA | 19 1/2" | 19" | 20" | 5° to 100° | 2 | 2 | 0000000 | 00000000 | 0000000 | 000000 |

| 8 psi 220 in. of H₂O | 147 cfm @ 0 | 13.3 in. of Hg 180 in. of H₂O | 7 1/2 | 19.8 A @ 208 V AC 19.5 A @ 230 V AC 9.7 A @ 460 V AC | 78 dBA | 18" | 18" | 19" | 5° to 100° | 2 | 2 | 0000000 | 00000000 | 0000000 | 000000 |

High-Flow Low-Pressure Hazardous Location Compressed Air Blowers

Safely produce high-flow compressed air with low pressure or vacuum in environments with flammable gases and combustible dust, such as propane and carbon-based dust. These blowers have an explosion-proof motor and are UL listed for use in hazardous locations. Also known as regenerative blowers, they are commonly used to operate pump drives, lift tables, and conveying systems. They can also be used for drying, exhausting, and aerating.

Overall | Pipe Size | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Pressure | Max. Flow Rate | Vacuum Rating | hp | Full Load Current | Vol., dBA | Lg. | Wd. | Ht. | Temp. Range, °F | Inlet | Outlet | Environmental Rating | Each | |

Three Phase, 208V AC/230V AC/460V AC (Inverter Rated) | ||||||||||||||

NPT Female Inlet and Outlet | ||||||||||||||

| 2 psi 50 in. of H2O | 556 cfm @ 0 psi | 3.7 in. of Hg 50 in. of H2O | 10 | 24.3 A @ 208 V AC 22.4 A @ 230 V AC 11.2 A @ 460 V AC | 81 | 25" | 20" | 22" | 5° to 100° | 4 | 4 | NEC Class I Division 1 Group D; NEC Class II Division 2 Groups F, G | 0000000 | 000000000 |

| 2 psi 60 in. of H2O | 471 cfm @ 0 psi | 4.4 in. of Hg 60 in. of H2O | 10 | 24.3 A @ 208 V AC 22.4 A @ 230 V AC 11.2 A @ 460 V AC | 81 | 25" | 19" | 22" | 5° to 100° | 4 | 4 | NEC Class I Division 1 Group D; NEC Class II Division 2 Groups F, G | 0000000 | 00000000 |

| 2 psi 68 in. of H2O | 381 cfm @ 0 psi | 5 in. of Hg 68 in. of H2O | 7 1/2 | 18.9 A @ 208 V AC 17.8 A @ 230 V AC 8.9 A @ 460 V AC | 80 | 23" | 18" | 19" | 5° to 100° | 3 | 3 | NEC Class I Division 1 Group D; NEC Class II Division 2 Groups F, G | 0000000 | 00000000 |

| 4 psi 116 in. of H2O | 294 cfm @ 0 psi | 8.8 in. of Hg 116 in. of H2O | 7 1/2 | 18.9 A @ 208 V AC 17.8 A @ 230 V AC 8.9 A @ 460 V AC | 80 | 23" | 16" | 19" | 5° to 100° | 3 | 3 | NEC Class I Division 1 Group D; NEC Class II Division 2 Groups F, G | 0000000 | 00000000 |

Overall | Pipe Size | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Pressure | Max. Flow Rate | Vacuum Rating | hp | Full Load Current | Vol., dBA | Lg. | Wd. | Ht. | Temp. Range, °F | Inlet | Outlet | Environmental Rating | Each | |

Three Phase, 208V AC/230V AC/460V AC (Inverter Rated) | ||||||||||||||

NPT Female Inlet and Outlet | ||||||||||||||

| 2 psi 115 in. of H2O | 274 cfm @ 0 psi | 8.5 in. of Hg 115 in. of H2O | 10 | 24.3 A @ 208 V AC 22.4 A @ 230 V AC 11.2 A @ 460 V AC | 81 | 27" | 20" | 22" | 5° to 100° | 4 | 4 | NEC Class I Division 1 Group D; NEC Class II Division 2 Groups F, G | 0000000 | 000000000 |

| 3 psi 110 in. of H2O | 220 cfm @ 0 psi | 8.1 in. of Hg 110 in. of H2O | 7 1/2 | 18.9 A @ 208 V AC 17.8 A @ 230 V AC 8.9 A @ 460 V AC | 78 | 27" | 19" | 22" | 5° to 100° | 4 | 4 | NEC Class I Division 1 Group D; NEC Class II Division 2 Groups F, G | 0000000 | 00000000 |

| 5 psi 150 in. of H2O | 167 cfm @ 0 psi | 11 in. of Hg 150 in. of H2O | 7 1/2 | 18.9 A @ 208 V AC 17.8 A @ 230 V AC 8.9 A @ 460 V AC | 77 | 23" | 18" | 19" | 5° to 100° | 2 | 2 | NEC Class I Division 1 Group D; NEC Class II Division 2 Groups F, G | 0000000 | 00000000 |

| 8 psi 240 in. of H2O | 128 cfm @ 0 psi | 11.9 in. of Hg 240 in. of H2O | 7 1/2 | 18.9 A @ 208 V AC 17.8 A @ 230 V AC 8.9 A @ 460 V AC | 75 | 27" | 16" | 19" | 5° to 100° | 2 | 2 | NEC Class I Division 1 Group D; NEC Class II Division 2 Groups F, G | 0000000 | 00000000 |

Oil- and Coolant-Collecting Air Cleaners

Often used in machine shops, these cleaners remove oil and coolant mist from the air. Air passes through a spinning drum.

Cleaners that cannot be sold to California are restricted due to energy efficiency requirements.

Cleaners | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Replacement Filters | |||||||||||||||

| Airflow, cfm | Volume | Power, hp | Voltage | Current | For Inlet Duct Dia. | Ht. | Wd. | Dp. | Mounting Fasteners Included | Mounting Hole Dia. | Includes | Cannot Be Sold To | Each | Each | ||

| 165 | 56 dB @ 15 ft. | 1/2 | 208V AC 240V AC 460V AC | 1.1A 2.2A 2.4A | 4" | 19" | 15" | 15" | No | 9/16" | Disposable Filter (Captures 98% of mist particles down to 1 micron) | __ | 000000 | 000000000 | 0000000 | 000000 |

| 380 | 58 dB @ 15 ft. | 1 | 208V AC 240V AC 460V AC | 2.1A 4.2A 4.6A | 4" | 21" | 17" | 22" | No | 9/16" | Disposable Filter (Captures 98% of mist particles down to 1 micron) | CA | 000000 | 00000000 | 0000000 | 00000 |

| 1,000 | 60 dB @ 15 ft. | 3 | 208V AC 240V AC 460V AC | 10.6A 4.8A 9.6A | 6" | 23" | 21" | 22" | No | 9/16" | Disposable Filter (Captures 98% of mist particles down to 1 micron) | CA | 000000 | 00000000 | 0000000 | 00000 |