Filter by

Overall Length

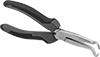

Jaw Capacity

Grip Style

Maximum Jaw Capacity

Sold As

Length

Circle Diameter

Finish

Pin Diameter

For Use With

OD

Jaw Length

Export Control Classification Number (ECCN)

Performance

DFARS Specialty Metals

Fastening and Joining

Facility and Grounds Maintenance

Fabricating and Machining

Fluid Handling

Electrical Power, Networking, and Controlling