About On/Off Valves

More

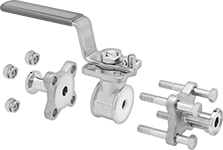

On/Off Valves with Sanitary Quick-Clamp Fittings for Food and Beverage

- For Use With: Food, Beverage

- Valve Type: Ball

- Specifications Met: FDA Compliant 21 CFR 177.1550

To maintain sanitary standards in food, beverage, and dairy systems that require frequent cleaning, these valves are made of FDA compliant materials. Polished to a 32 Ra finish, they have smooth internal surfaces that prevent product buildup and inhibit bacteria growth. All have sanitary quick-clamp fittings for easy disassembly. They also have a three-piece bolted body that comes apart for cleaning and inline access to internal components. Body is 316 stainless steel for excellent corrosion resistance. Valves have a lockable lever that can be fixed in place using a padlock (not included). They are full port, so they do not restrict flow.

Choose the seal material that suits your application. PTFE resists a broad range of food-processing chemicals, organic food acids, and fats and oils. Glass-filled PTFE won’t expand when exposed to water and heat, thanks to its glass reinforcement. More durable than unfilled PTFE, it’s good for high-stress applications. Polyethylene has a low-friction surface that prevents sticking and binding. This wear-resistant plastic handles scuffs and scrapes, and it won't degrade from food irradiation. It's often used in place of PTFE for applications where fluorocarbons can't be used.

Valves | Replacement Handles | Repair Kits | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Max. Pressure | Temperature Range, °F | End-to-End Lg. | For Max. Shackle Dia. | Interior Smoothness, Ra | Each | Each | Each | ||||

316 Stainless Steel Body—PTFE Plastic Seal | |||||||||||||

Quick Clamp × Quick Clamp | |||||||||||||

| 1/2" | 0.984" | 1000 psi @ 150° F | 0° | 300° | 4 5/16" | 1/4" | 32 | 000000000 | 0000000 | 000000000 | 000000 | 00000000 | 000000 |

| 3/4" | 0.984" | 1000 psi @ 150° F | 0° | 300° | 4 11/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 1" | 1.984" | 1000 psi @ 150° F | 0° | 300° | 5" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 1 1/2" | 1.984" | 1000 psi @ 150° F | 0° | 300° | 5 5/8" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 |

| 2" | 2.516" | 1000 psi @ 150° F | 0° | 300° | 6 7/16" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 |

| 2 1/2" | 3.047" | 800 psi @ 150° F | 0° | 300° | 7 13/16" | 3/8" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 |

| 3" | 3.579" | 800 psi @ 150° F | 0° | 300° | 9" | 3/8" | 32 | 000000000 | 00000000 | 000000000 | 00000 | 00000000 | 000000 |

| 4" | 4.682" | 800 psi @ 150° F | 0° | 300° | 9 5/8" | 3/8" | 32 | 000000000 | 00000000 | 000000000 | 000000 | 000000000 | 000000 |

316 Stainless Steel Body—Glass-Filled PTFE Plastic Seal | |||||||||||||

Quick Clamp × Quick Clamp | |||||||||||||

| 1/2" | 0.984" | 1000 psi @ 150° F | 0° | 300° | 4 5/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 3/4" | 0.984" | 1000 psi @ 150° F | 0° | 300° | 4 11/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 1" | 1.984" | 1000 psi @ 150° F | 0° | 300° | 5" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 1 1/2" | 1.984" | 1000 psi @ 150° F | 0° | 300° | 5 5/8" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 000000 |

| 2" | 2.516" | 1000 psi @ 150° F | 0° | 300° | 6 7/16" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 000000 |

316 Stainless Steel Body—Polyethylene Plastic Seal | |||||||||||||

Quick Clamp × Quick Clamp | |||||||||||||

| 1/2" | 0.984" | 700 psi @ 150° F | 0° | 150° | 4 5/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 3/4" | 0.984" | 700 psi @ 150° F | 0° | 150° | 4 11/16" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 |

| 1" | 1.984" | 700 psi @ 150° F | 0° | 150° | 5" | 1/4" | 32 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 000000 |

| 1 1/2" | 1.984" | 700 psi @ 150° F | 0° | 150° | 5 5/8" | 9/32" | 32 | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 |

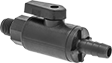

On/Off Valves with Push-to-Connect Fittings for Food and Beverage

Push tubing into the fittings on these valves and an internal gripping ring and O-ring hold it tight—no heat, solder, or flux required. These valves meet either NSF/ANSI standards or are FDA compliant for use with food. They also meet NSF/ANSI 61, so they’re safe to use with drinking water.

Polypropylene valves are flexible and can accommodate movement and vibration in your line without cracking.

Valves with a tube stem insert into the push-to-connect end of another fitting in place of a length of tubing. They’re good for tight spaces where a length of tube won’t fit.

Full-port valves do not restrict flow.

- Valve Type: Ball

- For Use With: Food, Beverage

- Seal Material: EPDM Rubber

- Specifications Met: See table

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Pipe Size | Max. Pressure | Temperature Range, °F | Seat Material | Port Type | End-to-End Lg. | Specifications Met | Each | |

Push to Connect × NPTF Male | |||||||||

| 1/4" | 1/8 | 150 psi @ 70° F | 35° to 200° | EPDM Rubber | Full | 2 1/4" | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1655, FDA Compliant 21 CFR 177.2600, NSF/ANSI 61 | 00000000 | 00000 |

- Valve Type: Ball

- For Use With: Food, Beverage

- Seal Material: EPDM Rubber

- Specifications Met: FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1655, FDA Compliant 21 CFR 177.2600, NSF/ANSI 61

Push-to-Connect

Tube Stem

- Valve Type: Ball

- For Use With: Food, Beverage

- Seal Material: EPDM Rubber

- Specifications Met: See table

| For Tube OD | Tube OD | Max. Pressure | Temperature Range, °F | Seat Material | Port Type | Port-to-Port Lg. | Specifications Met | Each | |

Push to Connect × Push-to-Connect Tube Stem | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4" | 3/8" | 150 psi @ 70° F | 35° to 200° | EPDM Rubber | Full | 1 1/2" | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1655, FDA Compliant 21 CFR 177.2600, NSF/ANSI 61 | 00000000 | 000000 |

| 3/8" | 3/8" | 150 psi @ 70° F | 35° to 200° | EPDM Rubber | Full | 1 1/2" | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1655, FDA Compliant 21 CFR 177.2600, NSF/ANSI 61 | 00000000 | 00000 |

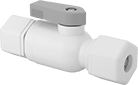

On/Off Valves with Barbed Fittings for Food and Beverage

- Valve Type: Ball

- For Use With: Food, Beverage

- Seal Material: See table

- Specifications Met: See table

To prevent leaks, these valves have barbed fittings that grip onto tubing to create a strong hold. They meet NSF/ANSI standards or are FDA compliant for use with food. All are full port, so they do not restrict flow.

Polypropylene valves also meet NSF/ANSI 61, so they’re safe to use in drinking water systems.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | For Tube ID | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Seal Material | End-to-End Lg. | Specifications Met | Each | |

White Polypropylene Plastic Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|

NPT Male × Barbed | |||||||||

| 1/4 | 1/4" | Not Rated | 125 psi @ 225° F | 0° to 210° | EPDM Rubber | 2 13/16" | NSF/ANSI 61, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1655, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

Barbed × Barbed | |||||||||

| __ | 1/4" | Not Rated | 125 psi @ 225° F | 0° to 210° | EPDM Rubber | 2 15/16" | NSF/ANSI 61, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1655, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

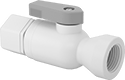

On/Off Valves with Compression Fittings for Food and Beverage

- Valve Type: Ball

- For Use With: Food, Beverage

- Seal Material: Buna-N Rubber

- Specifications Met: FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1655, FDA Compliant 21 CFR 177.2600

Control flow in lines where preventing leaks is critical, such as bottling lines. These valves have a compression sleeve that bites into tubing as you tighten the nut. They’re more secure than push-to-connect fittings. However, they’re more difficult to remove, so avoid using them in lines that require frequent disassembly. These valves are FDA compliant for direct contact with food. Made from polypropylene, they are hard and slippery to keep food from sticking. These valves resist chemicals and can handle harsh cleaners used in food equipment. They're full port valves, so they don't restrict flow.

| For Tube OD | Pipe Size | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Each | |

White Polypropylene Plastic Body | ||||||

|---|---|---|---|---|---|---|

Compression × Compression | ||||||

| 1/4" | __ | 150 psi @ 75° F | 35° to 200° | 2 15/16" | 0000000 | 00000 |

| 3/8" | __ | 150 psi @ 75° F | 35° to 200° | 3 3/16" | 0000000 | 0000 |

Compression × NPTF Female | ||||||

| 1/4" | 1/4 | 150 psi @ 75° F | 35° to 200° | 2 13/16" | 0000000 | 0000 |

| 3/8" | 3/8 | 150 psi @ 75° F | 35° to 200° | 2 15/16" | 0000000 | 0000 |

Compression × NPTF Male | ||||||

| 1/4" | 1/4 | 150 psi @ 75° F | 35° to 200° | 2 13/16" | 0000000 | 0000 |

| 3/8" | 3/8 | 150 psi @ 75° F | 35° to 200° | 2 15/16" | 0000000 | 0000 |