Filter by

Mount Type

Environment

Material

Capacity per Mount

Mounting Height

Food Industry Standard

Certification

REACH

Export Control Classification Number (ECCN)

DFARS Specialty Metals

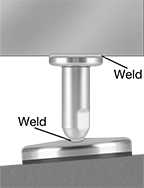

Sanitary Weld-On Swivel Leveling Mounts

With Rubber Cushion | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

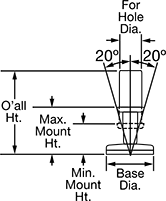

For Hole Dia., mm | Mounting Ht., mm | Swivel Range of Motion | Base Dia., mm | Food Industry Std. | Cap. per Mount, lb. | Overall Ht., mm | Cushion Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 52 | 56 to 85 | 20° | 109 | FDA Compliant 21 CFR 177.2600 | 6,000 | 151 | Buna-N | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 | 63 to 92 | 20° | 109 | FDA Compliant 21 CFR 177.2600 | 6,000 | 151 | Buna-N | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

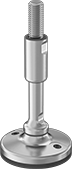

Stay-Put Sanitary Swivel Leveling Mounts with Threaded Stud

Leveling Mounts | Cap Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | With Rubber Cushion | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Thread Lg. | Mounting Ht. | Swivel Range of Motion | Base Dia. | No. of | Fasteners Included | Dia. | Ctr.-to-Ctr. Lg. | Food Industry Std. | Cap. per Mount, lb. | Overall Ht. | Cushion Material | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2 7/8" | 4" to 5 3/8" | 9° | 3 1/8" | 2 | No | 11/32" | 2 1/4" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 6,800 | 6 7/8" | Buna-N | 0000000 | 0000000 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4 1/8" | 5 3/16" to 7 3/4" | 9° | 3 1/8" | 2 | No | 11/32" | 2 1/4" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 5,400 | 9 1/4" | Buna-N | 0000000 | 000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2 7/8" | 4" to 5 3/8" | 9° | 4 1/16" | 2 | No | 1/2" | 3 1/8" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 9,800 | 6 7/8" | Buna-N | 0000000 | 000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4 1/8" | 5 3/16" to 7 3/4" | 9° | 4 1/16" | 2 | No | 1/2" | 3 1/8" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 9,800 | 9 1/4" | Buna-N | 0000000 | 000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 2 7/8" | 4" to 5 3/8" | 9° | 4 1/16" | 2 | No | 1/2" | 3 1/8" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 17,400 | 6 7/8" | Buna-N | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 4 1/8" | 5 3/16" to 7 3/4" | 9° | 4 1/16" | 2 | No | 1/2" | 3 1/8" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 17,400 | 9 1/4" | Buna-N | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

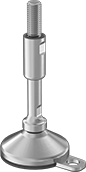

Stay-Put Sanitary Swivel Leveling Mounts with Threaded Stud and Offset Hole

Leveling Mounts | Cap Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | With Rubber Cushion | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Thread Lg. | Mounting Ht. | Swivel Range of Motion | Base Dia. | Fasteners Included | No. of | Dia. | Food Industry Std. | Cap. per Mount, lb. | Overall Ht. | Cushion Material | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2 7/8" | 4 5/16" to 5 11/16" | 10° | 3 1/8" | No | 1 | 19/32" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 7 3/16" | Buna-N | 0000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4 1/8" | 5 1/2" to 8 1/16" | 10° | 3 1/8" | No | 1 | 19/32" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 9 9/16" | Buna-N | 0000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2 7/8" | 4 5/16" to 5 11/16" | 10° | 3 1/8" | No | 1 | 19/32" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 7 3/16" | Buna-N | 0000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2 7/8" | 4 5/16" to 5 11/16" | 10° | 4 1/8" | No | 1 | 19/32" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 4,900 | 7 3/16" | Buna-N | 0000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4 1/8" | 5 1/2" to 8 1/16" | 10° | 3 1/8" | No | 1 | 19/32" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 9 9/16" | Buna-N | 0000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4 1/8" | 5 1/2" to 8 1/16" | 10° | 4 1/8" | No | 1 | 19/32" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 4,900 | 9 9/16" | Buna-N | 0000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 2 7/8" | 4 1/8" to 5 1/2" | 10° | 2 9/16" | No | 1 | 19/32" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 2,000 | 7" | Buna-N | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 2 7/8" | 4 5/16" to 5 11/16" | 10° | 3 1/8" | No | 1 | 19/32" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 7 3/16" | Buna-N | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Swivel Leveling Mounts with Threaded Stud

|

With Cushion |

Leveling Mounts | Cap Nuts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

With Rubber Cushion | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Thread Lg. | Mounting Ht. | Swivel Range of Motion | Base Dia. | Food Industry Std. | Cap. per Mount, lb. | Overall Ht. | Cushion Material | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3 3/8" | 4 1/8" to 5 1/2" | 10° | 2 9/16" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 2,000 | 7" | Buna-N | 000000 | 000000 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3 3/8" | 4 3/8" to 5 11/16" | 10° | 3 3/16" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 7 1/4" | Buna-N | 000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3 3/8" | 4 3/8" to 5 11/16" | 10° | 4 1/8" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 4,900 | 7 1/4" | Buna-N | 0000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4 1/2" | 5 5/16" to 7 7/8" | 10° | 2 9/16" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 2,000 | 9 3/8" | Buna-N | 000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 4 1/2" | 5 1/2" to 8 1/16" | 10° | 3 3/16" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 9 9/16" | Buna-N | 000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 3 3/8" | 4 1/8" to 5 1/2" | 10° | 2 9/16" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 2,000 | 7" | Buna-N | 000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 3 3/8" | 4 3/8" to 5 11/16" | 10° | 3 3/16" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 7 1/4" | Buna-N | 000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 3 3/8" | 4 3/8" to 5 11/16" | 10° | 4 1/8" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 4,900 | 7 1/4" | Buna-N | 0000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4 1/2" | 5 1/2" to 8 1/16" | 10° | 3 3/16" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 9 9/16" | Buna-N | 0000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 3 3/8" | 4 3/8" to 5 3/4" | 10° | 4 15/16" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 7,100 | 7 1/4" | Buna-N | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 2 7/8" | 4 1/8" to 5 1/2" | 10° | 2 9/16" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 2,000 | 7" | Buna-N | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 4 1/8" | 5 1/2" to 8 1/16" | 10° | 3 1/8" | 3-A Certified 88-00, FDA Compliant 21 CFR 177.2600 | 3,300 | 9 9/16" | Buna-N | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||