Filter by

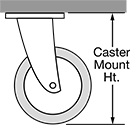

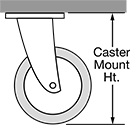

For Caster Mount Height

Material

Brake Extension Pedal Location

Mounting Location

Brake Retraction Pedal Location

Color

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Finish

REACH

RoHS

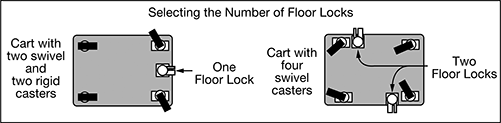

Floor Locks

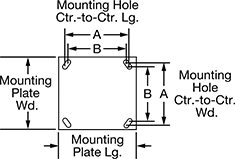

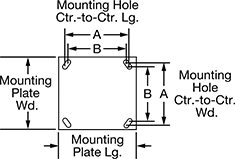

Mounting Plate Style 1

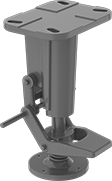

Stabilize carts, trucks, workbenches, and other mobile equipment during loading and unloading. Floor locks bolt or weld to the underside of your equipment and have a spring-loaded base with a nonskid floor pad to keep equipment stationary.

Note: Floor locks are not load rated. They are designed to brake your equipment in place, not lift it off the floor.

Pivoting base compensates for uneven floors.

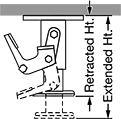

Retraction Pedal on Both Sides with Pivoting Base

Mounting Plate Style 1

Ht. | Mounting Plate | Mounting Hole Ctr.-to-Ctr. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Caster Mount Ht. | Extended | Retracted | Clearance | Style | Lg. | Wd. | Lg. (A) | Lg. (B) | Wd. (A) | Wd. (B) | Mounting Fasteners Included | For Screw Size | Color | Each | |

Painted Iron | |||||||||||||||

| 5 5/8"-5 7/8" | 5 5/8" | 4 9/16" | 1 5/16" | 1 | 4 13/16" | 4 1/4" | 3 5/8" | 3" | 3" | 2 5/8" | No | 3/8" | Gray | 00000000 | 0000000 |

| 7 1/4"-7 1/2" | 7 1/2" | 6" | 1 3/4" | 1 | 6 1/2" | 4 3/4" | 5 1/4" | 4 15/16" | 3 3/8" | 2 7/16" | No | 1/2" | Gray | 00000000 | 000000 |

| 10 1/4"-10 5/8" | 10 1/4" | 9 1/8" | 1 3/8" | 1 | 6 1/2" | 4 3/4" | 5 1/4" | 4 15/16" | 3 3/8" | 2 7/16" | No | 1/2" | Gray | 00000000 | 000000 |