How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

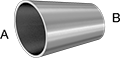

Butt-Weld Fittings for Stainless Steel Tubing

- For Use With: See table

- Temperature Range: See table

- Tubing:

304 Stainless Steel: Use with 304/304L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except DIN EN 10357 fittings with only ASTM A269 or ASTM A270

316 Stainless Steel: Use with 316/316L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except ASME BPE and DIN EN 10357 fittings with only ASTM A269 or ASTM A270 - Specifications Met: See table

Weld these fittings to tubing for a permanent, flush connection that permits smooth flow through a line.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

| For Tube OD (A) | For Tube OD (B) | Max. Pressure | Max. Vacuum | Temp. Range, °F | Wall Thick. | For Use With | Specifications Met | Each | ||

304/304L Stainless Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Polished | ||||||||||

| 1 | 1" | 3/4" | 200 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 000000000 | 000000 |

316/316L Stainless Steel | ||||||||||

Polished | ||||||||||

| 1 | 1" | 3/4" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 00000 |

Dull | ||||||||||

| 1 | 1" | 3/4" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

Offset straight reducers are also known as eccentric reducers. They have offset centers so your line can drain.

316/316L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD (A) | For Tube OD (B) | Max. Pressure | Max. Vacuum | Temp. Range, °F | Wall Thick. | For Use With | Specifications Met | Each | |

Polished | |||||||||

| 1" | 3/4" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 000000 |

Nuts with Built-In Sleeve for Plastic Compression Tube Fittings for Water

- Temperature Range: -40° to 200° F

- Tubing: Use with hard (Durometer 0D-75D) nylon plastic or polypropylene plastic

Use these nuts with plastic compression fittings to create a seal on plastic tubing. They have a built-in sleeve (ferrule), so the sleeve is positioned correctly for installation. Thread the nut onto the fitting, then insert the tubing and tighten the nut. Nuts are moisture-resistant acetal, so they won't absorb water and soften, even in high-humidity environments.

Nut | Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Material | Color | Max. Pressure | Pkg. Qty. | Pkg. | |

| 3/4" | Acetal Plastic | White | Nylon Plastic | White | 220 psi @ 72° F | 1 | 0000000 | 00000 |

Nuts with Built-In Sleeve for Plastic Compression Tube Fittings for Air

- For Use With: Air, Lubricated Air

- Temperature Range: -30° to 210° F

- Tubing: Use with firm or hard nylon plastic, polyethylene plastic or polypropylene plastic

Use these nuts with plastic compression fittings to create a seal on plastic tubing. They have a built-in sleeve (ferrule), so the sleeve is positioned correctly for installation. Thread the nut onto the fitting, then insert the tubing and tighten the nut. Nuts are polypropylene, which has excellent impact and abrasion resistance.

Nut | Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Material | Color | Max. Pressure | Pkg. Qty. | Pkg. | |

| 3/4" | Polypropylene Plastic | White | Polypropylene Plastic | White | 220 psi @ 72° F | 5 | 00000000 | 00000 |

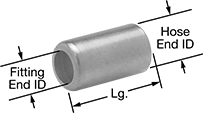

Crimp-On Ferrules for Air and Water Hose

Use ferrules to create a permanent connection between your air- and water-hose and barbed hose fittings. You will need a hose crimper (sold separately) for installation.

Brass and aluminum ferrules have good corrosion resistance. Choose a ferrule with an ID no more than 0.025" larger than your hose OD (measured with the fitting installed); also make sure the ferrule is at least as long as the barbed end of your fitting.

304 stainless steel ferrules offer very good corrosion resistance. Choose a ferrule with an ID no more than 0.031" larger than the hose OD (measured with the fitting installed).

| Hose End ID | Lg. | Fitting End ID | Pkg. Qty. | Pkg. | |

Brass | |||||

|---|---|---|---|---|---|

| 0.5" | 1" | 0.344" | 25 | 0000000 | 000000 |

| 0.525" | 1" | 0.375" | 25 | 0000000 | 00000 |

| 0.562" | 1" | 0.438" | 25 | 0000000 | 00000 |

| 0.593" | 1" | 0.438" | 25 | 0000000 | 00000 |

| 0.625" | 1" | 0.453" | 25 | 0000000 | 00000 |

| 0.656" | 1" | 0.438" | 25 | 0000000 | 00000 |

| 0.687" | 1" | 0.5" | 25 | 0000000 | 00000 |

| 0.718" | 1" | 0.625" | 25 | 0000000 | 00000 |

| 0.75" | 1" | 0.625" | 25 | 0000000 | 00000 |

| 0.781" | 1" | 0.625" | 25 | 0000000 | 00000 |

| 0.812" | 1" | 0.625" | 25 | 0000000 | 00000 |

304 Stainless Steel | |||||

| 0.53" | 1" | 0.438" | 5 | 0000000 | 0000 |

| 0.56" | 1" | 0.437" | 5 | 0000000 | 0000 |

| 0.593" | 1" | 0.438" | 5 | 0000000 | 0000 |

| 0.625" | 1" | 0.437" | 5 | 0000000 | 0000 |

| 0.656" | 1" | 0.437" | 5 | 0000000 | 0000 |

| 0.69" | 1" | 0.5" | 5 | 0000000 | 0000 |

| 0.718" | 1" | 0.625" | 5 | 0000000 | 0000 |

| 0.75" | 1" | 0.625" | 5 | 0000000 | 0000 |

Crimp-On Ferrules for Welding Hose

Use ferrules to create a permanent connection between your welding hose and barbed hose fittings. You will need a hose crimper (sold separately) for installation. Ferrules are brass for good corrosion resistance.

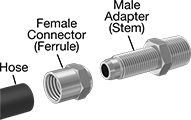

Screw-On Hose Fittings for Air and Water

The female connector screws directly onto rubber hose without the need for a separate adapter. You’ll need a female connector (ferrule) and a male adapter (stem) with the same hose ID to make a connection. Screw the female connector onto hose, then thread the male adapter into the female connector. When assembled, the fitting compresses against the hose, forming a strong seal. Also known as reusable fittings, they can be unscrewed from the hose end and used on a new hose.

303 stainless steel fittings have better corrosion resistance than brass fittings.