How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

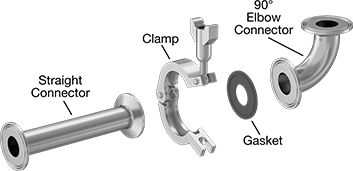

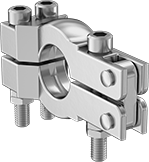

High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets

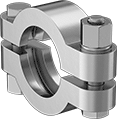

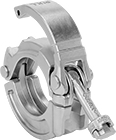

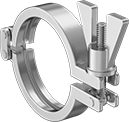

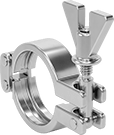

The smooth finish inside these fittings makes it easy to remove product residue. Also known as aseptic and tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for a fast and easy way to access your line. The pressure rating of the fitting will vary depending on the clamp you choose, and the temperature rating will vary based on the gasket material you choose.

Inch fittings connect to another same-size fitting and squeeze the gasket in between for a tight seal.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

3-A certified fittings comply with sanitary standards.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

- For Use With: Air, Beverage, Dairy, Food, Water

- Tubing:

Inch Fittings: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

Metric Fittings: Use with welded 304/304L or 316/316L stainless steel - Specifications Met: See table

Fittings with butt-weld end are also known as ferrules; they weld to tubing for a permanent, flush connection.

For Tube OD | |||||||

|---|---|---|---|---|---|---|---|

| Quick Clamp | Butt Weld | Flange OD | Lg. | Wall Thick. | Specifications Met | Each | |

Inch | |||||||

| 3" | 3" | 3.579" | 1 13/16" | 0.177" | 3-A Certified 63-04 | 00000000 | 000000 |

For Tube OD | ||||||||

|---|---|---|---|---|---|---|---|---|

| Quick Clamp | Butt Weld | Flange OD | Lg. | Wall Thick. | Specifications Met | Certification | Each | |

Inch | ||||||||

| 3" | 3" | 3.579" | 1 13/16" | 0.177" | 3-A Certified 63-04 | Material Certificate with Traceable Lot Number and Test Report | 000000000 | 000000 |

- For Use With: Air, Beverage, Dairy, Food, Water, except fittings with a 0.13" wall thickness cannot be used with dairy

- Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

- Specifications Met: See table

Fittings with butt-weld end are also known as ferrules; they weld to tubing for a permanent, flush connection. Tank butt-weld fittings have an extra-thick wall for welding.

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 3" | 3.579" | 350 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 3" | 3.579" | 350 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | For Tube Specifications Met | Each | |

| 3" | 3.579" | 304 Stainless Steel | 1,000 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Specifications Met | Each | |

| 3" | 3.579" | 350 psi @ 72° F | ASTM A269, ASTM A270 | ASME BPE | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 3" | 3.579" | 580 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 3" | 3.579" | 580 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | Specifications Met | Each | |

| 3" | 3.579" | 316 Stainless Steel | 1,300 psi @ 72° F | ASME BPVC.VIII | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 3" | 3.579" | 580 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 3" | 3.579" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

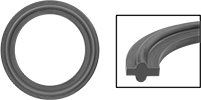

Buna-N gaskets are oil resistant. EPDM gaskets resist water and steam and work well in humid environments. Silicone gaskets withstand high temperatures. Fluoroelastomer gaskets stand up to fuel, oil, and acid condensates. PTFE gaskets withstand harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3" | 2.900" | 3.580" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

EPDM Rubber | ||||||||

| 3" | 2.900" | 3.580" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Silicone Rubber | ||||||||

| 3" | 2.900" | 3.580" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Fluoroelastomer Rubber | ||||||||

| 3" | 2.900" | 3.580" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 3" | 2.900" | 3.580" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

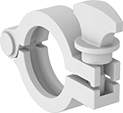

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

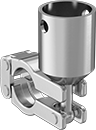

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 3" | 3.87" | 3.579" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 0000000 |

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 3" | 3.87" | 3.579" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 0000000 |

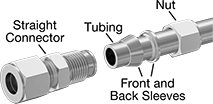

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | 0.035" | 1/2 | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 0000000 | 000000 |

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

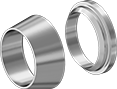

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each front sleeve, back sleeve, and nut is made of 316 stainless steel for excellent corrosion resistance. Five sets of sleeves and nuts come on each dispenser. Sleeves are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sets with Dispenser | |||||||||||

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 7/64" | 5 | 9/16" | 5 | 2,500 psi @ 72° F | 0000000 | 000000 |

PTFE sleeves are plastic instead of stainless steel, so they won’t damage tubing.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Tube Support Style | Temp. Range, °F | Each | |

| 3/8" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

Butt-Weld Fittings for Stainless Steel Tubing

- For Use With: See table

- Temperature Range: See table

- Tubing:

304 Stainless Steel: Use with 304/304L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except DIN EN 10357 fittings with only ASTM A269 or ASTM A270

316 Stainless Steel: Use with 316/316L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except ASME BPE and DIN EN 10357 fittings with only ASTM A269 or ASTM A270 - Specifications Met: See table

Weld these fittings to tubing for a permanent, flush connection that permits smooth flow through a line.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

| For Tube OD | Thread Type | Pipe Size | Max. Pressure | Max. Vacuum | Temp. Range, °F | Wall Thick. | For Use With | Each | |

304/304L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Polished | |||||||||

| 2" | NPT | 2 | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | 000000000 | 000000 |

316/316L Stainless Steel | |||||||||

Polished | |||||||||

| 2" | NPT | 2 | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | 00000000 | 00000 |

| For Tube OD | Thread Type | Pipe Size | Max. Pressure | Max. Vacuum | Temp. Range, °F | Wall Thick. | For Use With | Each | |

304/304L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Polished | |||||||||

| 2" | NPT | 2 | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | 000000000 | 000000 |

| 2 1/2" | NPT | 2 1/2 | 450 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | 000000000 | 000000 |

316/316L Stainless Steel | |||||||||

Polished | |||||||||

| 2" | NPT | 2 | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.065" | Air, Food, Water | 00000000 | 000000 |

Vibration-Resistant Ultra-High-Polish Gasket Fittings for Stainless Steel Tubing

- For Use With: Carbon Dioxide, Ammonia, Chloride, Fluoride, Fluorine, Germane, Fluorocarbon, Halide, Helium, Hydrogen, Argon, Krypton, Oxygen, Laser Gas, Natural Gas, Neon, Butane, Xenon, Tungsten Hexafluoride, Silane, Sulfur Hexafluoride, Nitrogen

- Temperature Range: -420° to 1000° F, except nickel gaskets are -325° to 600° F

- Tubing: Use with 316/316L stainless steel

- Specifications Met: MIL-STD-810

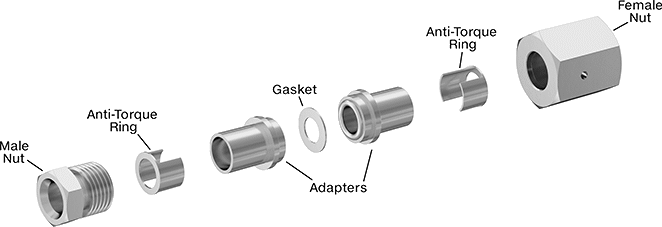

Use these fittings in applications ranging from semiconductor manufacturing to satellites and rockets. They resist high vibration and ultra-high vacuum while maintaining high purity. Two anti-torque rings stop the fittings from twisting your tubing or component during installation. This also prevents the fittings from loosening or leaking from high vibration, so they’re safe to use with hazardous gases. All are compatible with Swagelok® VCR fittings.

Also known as ultra-high-purity fittings, these fittings were packed in a Class 100 clean room, so they arrive without contaminants. They're also designed from inside and out to prevent the creation of contaminants. Made of stainless steel, they won’t rust. Their anti-torque rings prevent galling, which extends the life of the seal while limiting particles. A metal gasket, instead of a rubber one, also reduces the potential for particles. And their interior is polished to a 7 Ra finish—the same as a high-quality stainless steel sink—to prevent particles from clinging to the inside.

Choose from fully assembled fittings or build a custom fitting. For a complete fitting, you'll need two anti-torque rings, two adapters, a male and female nut, and a gasket.

| For Tube OD | Wall Thickness | Lg. | Material | Gasket Material | Max. Pressure | Max. Vacuum | Includes | Each | |

| 1/4" | 0.035" | 1 13/16" | 316/316L Stainless Steel | Nickel | 4,000 psi @ 72° F | 10 -11 torr @ 72° F | Two Adapters, Two Anti-Torque Rings, Gasket, Male Nut, Female Nut | 0000000 | 000000 |

Caps replace a female nut to close off the end of a line.

| For Tube OD | Material | Max. Pressure | Max. Vacuum | Each | |

| 1/4", 3/8" | 316/316L Stainless Steel | 4,000 psi @ 72° F | 10 -11 torr @ 72° F | 0000000 | 000000 |

Plugs replace a male nut to close off the end of a line.

| For Tube OD | Material | Max. Pressure | Max. Vacuum | Each | |

| 1/4", 3/8" | 316/316L Stainless Steel | 4,000 psi @ 72° F | 10 -11 torr @ 72° F | 0000000 | 000000 |

Nickel gaskets are softer than stainless steel gaskets, so they won’t wear down sealing surfaces as much, and they’re easier to tighten. However, they don’t withstand temperatures as high. They’re reactive to carbon monoxide and ozone, so they shouldn’t be used with those chemicals.

Stainless steel gaskets are a more universal gasket material than nickel gaskets. They’re also stronger and better at handling high temperatures. You can use them with carbon monoxide and ozone. However, they’re harder to tighten than nickel gaskets, and they’ll wear down sealing surfaces more quickly.

| For Tube OD | Material | Max. Vacuum | Each | |

| 1/4" | 316/316L Stainless Steel | 10 -11 torr @ 72° F | 0000000 | 000000 |