How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

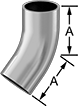

Butt-Weld Fittings for Stainless Steel Tubing

- For Use With: See table

- Temperature Range: See table

- Tubing:

304 Stainless Steel: Use with 304/304L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except DIN EN 10357 fittings with only ASTM A269 or ASTM A270

316 Stainless Steel: Use with 316/316L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except ASME BPE and DIN EN 10357 fittings with only ASTM A269 or ASTM A270 - Specifications Met: See table

Weld these fittings to tubing for a permanent, flush connection that permits smooth flow through a line.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

| For Tube OD | Max. Pressure | Max. Vacuum | Temp. Range, °F | Lg. (A) | Wall Thick. | For Use With | Specifications Met | Each | |

304/304L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Polished | |||||||||

| 1" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 1 3/16" | 0.065" | Dairy, Food | 3-A Certified 63-04 | 00000000 | 000000 |

Dull | |||||||||

| 1" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 1 3/16" | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

316/316L Stainless Steel | |||||||||

Polished | |||||||||

| 1" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 1 3/16" | 0.065" | Dairy, Food | 3-A Certified 63-04 | 0000000 | 00000 |

Dull | |||||||||

| 1" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 1 3/16" | 0.065" | Air, Food, Water | __ | 00000000 | 00000 |

Sleeves for 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

- Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube OD | |||

|---|---|---|---|

| Inch | Sleeve Material | Each | |

Inch | |||

| 2" | 316 Stainless Steel | 000000000 | 0000000 |

Sleeves for Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

Use these sleeves with precision AN nuts and fittings to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. They are also known as ferrules.

304 stainless steel sleeves have very good corrosion resistance. 316 stainless steel sleeves have excellent corrosion resistance.