Filter by

Application

Weight Capacity

Thickness

Inside Width

Material

Inside Length

Specifications Met

Export Control Classification Number (ECCN)

DFARS Specialty Metals

About Chain

Find a chain style and capacity that's up to any task, from hanging a 5 lb. light fixture to rigging a 17 ton generator.

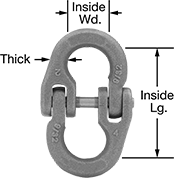

Removable Figure-Eight Chain Connecting Links—For Lifting

For Straight-Link Chain Trade Size | Thk. | Inside Lg. | Inside Wd. | Wt. Cap., lb. | Fabrication | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Grade 120 Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Powder-Coated Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 29/64" | 2 31/64" | 13/16" | 5,200 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 9/16" | 2 7/16" | 1 1/64" | 6,600 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 45/64" | 3 1/16" | 1 9/64" | 10,600 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 7/8" | 4 13/64" | 1 19/64" | 17,900 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 1/16" | 5 1/32" | 2 3/8" | 27,500 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Grade 100 Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 5/16" | 1 47/64" | 35/64" | 2,700 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 25/64" | 2 3/32" | 43/64" | 4,300 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 15/32" | 2 7/16" | 3/4" | 5,700 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 19/32" | 2 53/64" | 15/16" | 8,800 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 51/64" | 3 15/32" | 1 7/64" | 15,000 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 15/16" | 4 13/32" | 1 11/32" | 22,600 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 17/64" | 4 31/32" | 1 47/64" | 35,300 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 11/32" | 6 5/16" | 2" | 42,700 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Orange Painted Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 5/16" | 1 47/64" | 35/64" | 2,700 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 25/64" | 2 3/32" | 43/64" | 4,300 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 15/32" | 2 7/16" | 3/4" | 5,700 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 19/32" | 2 53/64" | 15/16" | 8,800 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 51/64" | 3 15/32" | 1 7/64" | 15,000 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 15/16" | 4 13/32" | 1 11/32" | 22,600 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 17/64" | 4 31/32" | 1 47/64" | 35,300 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 27/64" | 6 3/16" | 2 1/16" | 42,700 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Grade 80 Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1/4" | 1 13/32" | 29/64" | 2,100 | Forged | ASME B30.9, ASTM A952 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 5/16" | 1 15/16" | 9/16" | 3,500 | Forged | ASME B30.9, ASTM A952 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1/2" | 2 27/64" | 13/16" | 7,100 | Forged | ASME B30.9, ASTM A952 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 45/64" | 3 33/64" | 1 5/32" | 12,000 | Forged | ASME B30.9, ASTM A952 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 13/16" | 4 1/16" | 1 13/32" | 18,100 | Forged | ASME B30.9, ASTM A952 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 15/16" | 4 25/32" | 1 23/32" | 28,300 | Forged | ASME B30.9, ASTM A952 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 3/64" | 5 1/4" | 1 57/64" | 34,200 | Forged | ASME B30.9, ASTM A952 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Grade 63 Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2205 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 9/32" | 1 7/16" | 1/2" | 1,300 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 3/8" | 2 1/8" | 11/16" | 2,750 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 33/64" | 2 7/8" | 15/16" | 5,500 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 11/16" | 3 5/8" | 1 1/8" | 9,350 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 53/64" | 4 1/16" | 1 7/16" | 13,800 | Forged | ASME B30.9, OSHA Compliant 29 CFR 1910.184 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

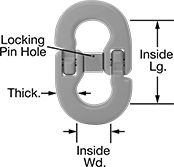

Nonremovable Figure-Eight Chain Connecting Links—For Lifting

For Straight-Link Chain Trade Size | Thk. | Inside Lg. | Inside Wd. | Wt. Cap., lb. | Fabrication | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Grade 100 Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Orange Powder-Coated Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 25/64" | 2 3/32" | 43/64" | 4,300 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 19/32" | 2 53/64" | 15/16" | 8,800 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 51/64" | 3 15/32" | 1 7/64" | 15,000 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 53/64" | 4 1/16" | 1 5/16" | 22,600 | Forged | ASME B30.9, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

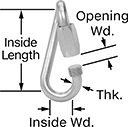

90° Twist Quick Links

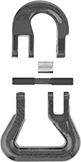

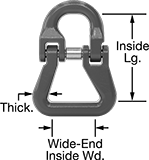

Removable Triangle-Shaped Chain Connecting Links—For Lifting

For Straight-Link Chain Trade Size | Thk. | Inside Lg. | Wide End Inside Wd. | Wt. Cap., lb. | Fabrication | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Grade 100 Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Powder-Coated Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 7/16" | 2 19/32" | 1 3/16" | 5,700 | Forged | ASME B30.26, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1/2" | 3 3/16" | 1 9/16" | 8,800 | Forged | ASME B30.26, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | 4 3/32" | 1 31/32" | 15,000 | Forged | ASME B30.26, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 13/16" | 4 7/16" | 2 9/16" | 22,600 | Forged | ASME B30.26, ASTM A952, OSHA Compliant 29 CFR 1910.184 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||