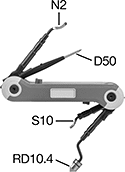

Multitool-Style Deburring Scrapers

Debur here, scrape there, countersink anywhere—these scrapers are the Swiss Army knife for deburring. They include four of the most common blades for finishing flat and round edges on the go.

Blade | ||||||||

|---|---|---|---|---|---|---|---|---|

| Tools Included | Material | Style | Closed Lg. | Overall Lg. | Handle Material | For Use On | Each | |

For Deburring Straight Edges, Front Hole Edges, and Flat Surfaces | ||||||||

| Deburring Blade D50 Deburring Blade N2 Deburring Blade S10 Countersink Blade RD10.4 | Steel | Fixed, Rotating | 5 1/4" | 11 1/2" | Plastic | Steel, Aluminum, Brass, Cast Iron, Plastic | 0000000 | 000000 |

Blade | Overall | Each | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Deburring Blade Manufacturer No. | Material | Style | Lg. | Wd. | Shank Dia. | For Deburring | 1-9 | 10-Up | |

| D50 | Steel | Fixed | 1.97" | 0.1" | __ | Straight Edges, Flat Surfaces | 0000000 | 00000 | 00000 |

| N2 | Steel | Rotating | 0.90" | 0.36" | 0.1" | Straight Edges, Front Hole Edges | 0000000 | 0000 | 0000 |

| S10 | Steel | Rotating | 1.85" | 0.43" | 0.125" | Straight Edges, Front Hole Edges | 0000000 | 0000 | 0000 |

| Body Dia. | Material | Each | |

| 3/8" | Steel | 00000000 | 000000 |

Deburring Blades

Choose from a range of blade shapes to scrape burs from flat surfaces to tube edges. Insert blades with a 0.1" dia. shank into a changeable-blade deburring scraper. For blades without a shank, they require a blade holder (sold separately); they are only for use with adjustable-length deburring scrapers, which secure the blade holder.

Blades with a left-hand cut direction are more comfortable for left-handed users to operate. Double-sided blades have cutting edges on both ends, so they last twice as long as a single-sided blade.

Carbide blades are harder than steel and cobalt blades, stay sharp longer, and withstand higher temperatures. Use them for deburring tough materials, such as hardened steel.

Overall | Blade | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | Shank Dia. | Material | Style | 1-9 | 10-Up | ||

Neutral Cut Direction | ||||||||||

| A | Brass, Iron | B20, N2 | 0.90" | 0.36" | 0.1" | Steel | Rotating | 0000000 | 00000 | 00000 |

Blades | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Blade | Each | Required Chuck-Style Hand Vises | Required Blade Holder | ||||||||||

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | Material | Style | Features | 1-9 | 10-Up | Each | Each | ||||

Right-Hand Cut Direction | ||||||||||||||

| B | Steel, Aluminum, Plastic | D50 | 1.97" | 0.1" | Steel | Fixed | __ | 0000000 | 00000 | 00000 | 000000 | 00 | 000000 | 00 |

Neutral Cut Direction | ||||||||||||||

| B | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel | C40, T50 | 1.50" | 0.16" | Steel | Fixed | __ | 0000000 | 0000 | 0000 | 000000 | 00 | 0000000 | 00000 |

| B | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel | C42, T70 | 1.75" | 0.31" | Steel | Fixed | __ | 0000000 | 00000 | 00000 | 000000 | 00 | 0000000 | 0000 |

| B | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel, Wood | C50, T120 | 3.50" | 0.3" | Steel | Fixed | Double-Sided | 0000000 | 00000 | 00000 | 0000000 | 000000 | 000000 | 00 |

Blades | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Blade | Each | Required Blade Holder | |||||||||

| For Use On | Deburring Blade Manufacturer Number | Lg. | Dia. | For Max. Hole Dia. | Material | Style | 1-9 | 10-Up | Each | |||

Right-Hand Cut Direction | ||||||||||||

| D | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel | C12, F12 | 1.13" | 0.5" | 1/2" | Steel | Fixed | 0000000 | 000000 | 000000 | 0000000 | 00000 |

| D | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel | C20, F20 | 1.13" | 0.75" | 3/4" | Steel | Fixed | 0000000 | 00000 | 00000 | 0000000 | 0000 |

| D | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel | C30, F30 | 1.75" | 1.27" | 1 3/16" | Steel | Fixed | 0000000 | 00000 | 00000 | 0000000 | 0000 |

Overall | Blade | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | Shank Dia. | Material | Style | 1-9 | 10-Up | ||

Neutral Cut Direction | ||||||||||

| E | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel, Wood | B32 | 0.75" | 0.25" | 0.1" | Steel | Rotating | 0000000 | 00000 | 00000 |

Blades | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Blade | Each | Required Blade Holder | |||||||||

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | For Max. Material Thick. | Material | Style | 1-9 | 10-Up | Each | |||

Left-Hand Cut Direction | ||||||||||||

| J | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel, Hardened Steel | D80C | 0.63" | 0.63" | 1/8" | Carbide | Fixed | 0000000 | 00000 | 00000 | 0000000 | 00000 |

Blades | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Blade | Each | Required Blade Holder | |||||||||

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | For Max. Material Thick. | Material | Style | 1-9 | 10-Up | Each | |||

Neutral Cut Direction | ||||||||||||

| L | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel, Hardened Steel | D82C, L3 | 0.75" | 0.55" | 11/32" | Carbide | Fixed | 0000000 | 000000 | 000000 | 0000000 | 00000 |

| N | Steel, Aluminum, Copper, Brass, Plastic | D85 | 0.54" | 0.69" | 7/32" | Steel | Fixed | 0000000 | 00000 | 00000 | 0000000 | 0000 |

Blades | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Blade | Each | Required Blade Holder | |||||||||

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | For Keyway Wd. | Material | Style | 1-9 | 10-Up | Each | |||

Left-Hand Cut Direction | ||||||||||||

| Q | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel | G10 | 0.50" | 0.5" | 19/32" | Steel | Fixed | 0000000 | 00000 | 00000 | 0000000 | 00000 |

| Q | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel | G20 | 0.37" | 0.37" | 3/8" | Steel | Fixed | 0000000 | 0000 | 0000 | 0000000 | 0000 |

| Q | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel, Hardened Steel | G40C | 0.37" | 0.37" | 3/8" | Carbide | Fixed | 0000000 | 0000 | 0000 | 0000000 | 0000 |

Heavy Duty Deburring Blades

Longer than standard blades, these are designed for more frequent use. Insert them into a heavy duty changeable-blade deburring scraper.

Cobalt steel blades are stronger and more durable than plain steel blades.

Left-hand blades cut counterclockwise, so they’re comfortable for left-handed users to operate.

Overall | Blade | Each | |||||||

|---|---|---|---|---|---|---|---|---|---|

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | Shank Dia. | Material | Style | 1-9 | 10-Up | |

Right-Hand Cut Direction | |||||||||

| Steel, Aluminum | E100, S10 | 1.85" | 0.43" | 0.125" | Steel | Rotating | 0000000 | 00000 | 00000 |

Neutral Cut Direction | |||||||||

| Steel, Aluminum, Brass, Cast Iron, Plastic, Wood | E200S | 1.88" | 7/16" | 0.125" | Cobalt Steel | Rotating | 00000000 | 0000 | 0000 |

Overall | Blade | Each | |||||||

|---|---|---|---|---|---|---|---|---|---|

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | Shank Dia. | Material | Style | 1-9 | 10-Up | |

Neutral Cut Direction | |||||||||

| Steel, Aluminum, Copper, Brass, Plastic, Stainless Steel, Cast Iron, Wood | E400 | 2.06" | 0.12" | 0.125" | Steel | Fixed | 0000000 | 00000 | 00000 |

Overall | Blade | Each | |||||||

|---|---|---|---|---|---|---|---|---|---|

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | Shank Dia. | Material | Style | 1-9 | 10-Up | |

Neutral Cut Direction | |||||||||

| Steel, Aluminum, Brass, Cast Iron, Plastic, Stainless Steel, Wood | E320 | 1.88" | 7/16" | 0.125" | Steel | Rotating | 00000000 | 00000 | 00000 |

| Steel, Aluminum, Brass, Cast Iron, Plastic, Wood | E720 | 2.13" | 7/16" | 0.125" | Steel | Rotating | 00000000 | 0000 | 0000 |

Overall | Blade | Each | |||||||

|---|---|---|---|---|---|---|---|---|---|

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | Shank Dia. | Material | Style | 1-9 | 10-Up | |

Right-Hand Cut Direction | |||||||||

| Steel, Aluminum, Copper, Brass, Cast Iron, Stainless Steel, Hardened Steel, Plastic | E707 | 2.13" | 7/16" | 0.125" | Steel | Rotating | 00000000 | 00000 | 00000 |

Overall | Blade | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Use On | Deburring Blade Manufacturer Number | Lg. | Wd. | Shank Dia. | For Max. Material Thick. | Material | Style | 1-9 | 10-Up | |

Left Hand Cut Direction | ||||||||||

| Steel, Aluminum, Copper, Brass, Cast Iron, Stainless Steel, Plastic | E755 | 1.44" | 0.12" | 0.125" | 1/32" | Steel | Fixed | 0000000 | 00000 | 00000 |

Changeable-Blade Deburring Scraper and Countersink Sets

Each set comes with multiple blades and one or more handles. Switch out the blades to tackle different tasks.

Style B sets have blades coated with titanium nitride—they hold up against repeated use better than standard deburring blades.

Style D sets have seven handles, so you can keep multiple scrapers ready without swapping blades.

Style E sets have a ceramic blade to finish plastic 3D-printed and injection-molded parts. It won’t rust and will stay sharp longer than steel blades when used on plastic and soft metal.

| Number of Pieces | For Deburring | For Use On | Includes | For Blade Shank Dia. | Blade Style | Container Type | Each | |

| 12 | Straight Edges, Front Hole Edges, Back Hole Edges, Flat Surfaces | Steel, Aluminum, Copper, Brass, Cast Iron, Stainless Steel, Plastic, Wood | One B10 Steel Blade One B20 Steel Blade One B30 Steel Blade One B50 Steel Blade One B60 Steel Blade One C40 Steel Blade One E100 Steel Blade One E300 Steel Blade Three Blade Holders One 4 1/2” Lg. Plastic Handle | 0.1", 0.125" | Rotating | Plastic Case | 00000000 | 000000 |

| Number of Pieces | For Deburring | For Use On | Includes | For Blade Shank Dia. | Blade Style | Container Type | Each | |

| 11 | Straight Edges, Front Hole Edges, Back Hole Edges | Steel, Aluminum, Copper, Brass, Cast Iron, Stainless Steel, Plastic, Wood | One B10P Titanium Nitride (TiN)-Coated Steel Blade One B11P Titanium Nitride (TiN)-Coated Steel Blade One B20P Titanium Nitride (TiN)-Coated Steel Blade One B30P Titanium Nitride (TiN)-Coated Steel Blade One E100P Titanium Nitride (TiN)-Coated Steel Blade One E111P Titanium Nitride (TiN)-Coated Steel Blade One E200P Titanium Nitride (TiN)-Coated Steel Blade One E300P Titanium Nitride (TiN)-Coated Steel Blade Two Blade Holders One 4 1/8” Lg. Aluminum Handle | 0.1", 0.125" | Rotating | Plastic Case | 00000000 | 000000 |

|  Inner Keyway |  Outer Keyway |  Back Hole Edge |  Flat Surface |

Front Hole Edge | Sheet Edge |  Straight Edge |

| Number of Pieces | For Deburring | For Use On | Includes | For Blade Shank Dia. | Blade Style | Container Type | Each | |

| 22 | Straight Edges, Front Hole Edges, Back Hole Edges, Flat Surfaces, Sheet Edges, Inner Keyways, Outer Keyways | Steel, Aluminum, Brass, Cast Iron, Plastic | One C20 Countersink One D50 Steel Blade One D66 Steel Blade One L3 Steel Blade One N80K Steel Blade One S20 Steel Blade One S30 Steel Blade One S100 Cobalt Steel Blade One T80 Steel Blade Six Blade Holders One 4 3/4" Lg. Aluminum Handle Six 4 3/4" Lg. Plastic and Rubber Handles | 0.1" | Fixed, Rotating | Plastic Case | 00000000 | 0000000 |

| Number of Pieces | For Deburring | For Deflashing | For Use On | Includes | For Blade Shank Dia. | Blade Style | Container Type | Each | |

| 11 | Straight Edges, Front Hole Edges, Back Hole Edges, Flat Surfaces, Sheet Edges, Inner Keyways, Outer Keyways | Parting Lines, Mold Gates | Steel, Aluminum, Copper, Brass, Cast Iron, Stainless Steel, Hardened Steel, Plastic, Wood | One B10 Steel Blade One B11 Steel Blade One B25 Steel Blade One E111 Blade One E250 Steel Blade One E400 Steel Blade One E707 Steel Blade Two Blade Holders One Ceramic Blade with 5 3/4” Lg. Plastic Handle One 4 1/2” Lg. Plastic Handle | 0.1", 0.125" | Fixed, Rotating | Plastic Case | 00000000 | 000000 |

|  Inner Keyway |  Outer Keyway |  Outer Tube Edge |  Back Hole Edge |

Front Hole Edge | Sheet Edge |  Straight Edge |

| Number of Pieces | For Deburring | For Use On | Includes | For Blade Shank Dia. | Blade Style | Container Type | Each | |

| 24 | Straight Edges, Front Hole Edges, Back Hole Edges, Outer Tube Edges, Sheet Edges, Inner Keyways, Outer Keyways | Steel, Aluminum, Brass, Cast Iron, Plastic | One C20 Countersink One EX18 Countersink One 10.4 mm Countersink One D50 Steel Blade One D66 Steel Blade One N1 Steel Blade One N2 Steel Blade One N80K Steel Blade One S10 Steel Blade One S20 Steel Blade One S30 Steel Blade One S150 Steel Blade One Steel Cylinder Double Bur Six Blade Holders One 4 1/2” Lg. Aluminum Handle One 6 7/8” Lg. Plastic and Steel Handle Two 4 3/4” Lg. Plastic and Rubber Handles One Hex Key | 0.1", 0.125" | Fixed, Rotating | Plastic Case | 00000000 | 0000000 |

Changeable-Blade Sheet Metal Deburring Scrapers

Swap out the blades on these scrapers to smooth sheet metal in different thicknesses. The V-shaped blades remove burs from both sides of an edge at the same time. Pull the collar down to change blades. You can also slide the blade holder in or out of the handle and lock it at any length you need.

Handle | Blade | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Material | Grip Style | Includes | For Deburring | For Use On | Overall Lg. | Material | Style | Each | |

| 4 3/4" | Plastic | Cushion | One D80C Blade One D-Style Blade Holder One Handle | Flat Surfaces, Sheet Edges | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel, Hardened Steel | 5 3/4"-9" | Carbide | Fixed | 00000000 | 000000 |

Overall | Blade | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Use On | Deburring Blade Manufacturer No. | Lg. | Wd. | For Max. Material Thick. | Material | Style | 1-9 | 10-Up | ||

Left-Hand Cut Direction | ||||||||||

| J | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel, Hardened Steel | D80C | 0.63" | 0.63" | 1/8" | Carbide | Fixed | 0000000 | 00000 | 00000 |

Overall | Blade | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Use On | Deburring Blade Manufacturer No. | Lg. | Wd. | For Max. Material Thick. | Material | Style | 1-9 | 10-Up | ||

Neutral Cut Direction | ||||||||||

| L | Steel, Aluminum, Copper, Brass, Cast Iron, Plastic, Stainless Steel, Hardened Steel | D82C, L3 | 0.75" | 0.55" | 11/32" | Carbide | Fixed | 0000000 | 000000 | 000000 |

| N | Steel, Aluminum, Copper, Brass, Plastic | D85 | 0.54" | 0.69" | 7/32" | Steel | Fixed | 0000000 | 00000 | 00000 |

Portable Digital Hardness Testers

Quickly test large parts or metal bar stock with our most precise hardness testers. These testers are portable and can be brought to facilities and jobsites to test items that are too large to move. While some hardness testers only work on one type of metal, these testers work on most metals. They have a rebound hammer that bounces back after impact—the distance it rebounds indicates the hardness of your surface. To obtain accurate readings, steel and other hard metals must be at least 1” thick and aluminum and other soft metals must be at least 3” thick.

Convert your measurements between Rockwell, Vickers, Brinell, or Shore hardness ratings. Your readings will show on a backlit digital display so you can test even in low light. Store up to 100 measurements with their built-in memory or transfer the data to your PC using the USB port.

Probe | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hardness Measuring Range (For Scale) | Accuracy | Ht. | Wd. | Dia. | Cable Lg. | Min. Material Thick. | Batteries Included | Includes | Each | |

For Use On Aluminum, Brass, Bronze, Copper, Cast Iron, Iron, Alloy Steel, Stainless Steel, Steel | ||||||||||

| Brinell 93-650 Durometer 0-100 (A, D, OO) Leeb 100-950 (D) Rockwell 20-100 (B, C) Vickers 83-976 | ±0.5% | 1 1/4" | 2 7/8" | 3/32" | 58" | 1" | Yes | Carrying Case, Cleaning Brush, Test Block | 0000000 | 000000000 |

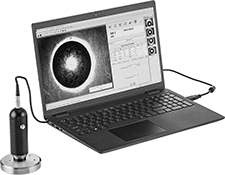

Digital Scopes for Brinell Hardness Testers

Finding your Brinell hardness doesn’t have to be so hard—these scopes scan and measure indents, then calculate the hardness for you. Accurate and efficient, these scopes replace the need for bulky microscopes and manually measuring and calculating hardness. Connect these scopes to your computer and use the included software to see a live image of the indent on your screen. You can zoom in 4X and adjust the focus to capture a wide range of indent diameters. To fine tune the automatic measurement, simply drag your cursor. Use the software to set test parameters, convert the value to other hardness scales, and validate the test results. The software also marks any measurements that fall out of your set specifications. When you’re finished, you can generate a customizable Microsoft Word or Excel report for your records.

| For Ball Indenter Dia., mm | Hardness Measuring Range | Focus Type | Camera Megapixels | Resolution | Number of Lenses | Ht. | Dia. | Housing Material | Computer Compatibility | Includes | Each | |

For Use On Aluminum, Brass, Bronze, Cast Iron, Iron, Alloy Steel, Stainless Steel, Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.8-6 | 8-650 | Adjustable | 1.3 | 0.0001 | 2 | 4 3/4" | 1 1/2" | Aluminum | PC | Carrying Case, One Calibrated Test Block, Software, USB Cable | 0000000 | 000000000 |