Filter by

Material

Mount Type

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Orientation

T-Tracks

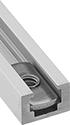

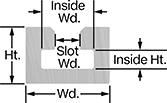

Single-Profile Straight T-Tracks

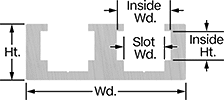

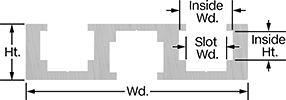

Inside | Mounting Holes | For Mounting Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | Width | Height | Mounting Fasteners Included | Number of | Center-to-Center | Size | Head Style | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Wide Slot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 3/4" | 1/2" | 1/2" | 1/4" | No | 2 | 3" | No. 10 | Pan | Anodized Aluminum | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 3/4" | 1/2" | 1/2" | 1/4" | No | 4 | 3" | No. 10 | Pan | Anodized Aluminum | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 3/4" | 1/2" | 1/2" | 1/4" | No | 6 | 3" | No. 8 | Pan | Anodized Aluminum | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 3/4" | 1/2" | 1/2" | 1/4" | No | 8 | 3" | No. 8 | Pan | Anodized Aluminum | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 3/4" | 1/2" | 1/2" | 1/4" | No | 12 | 3" | No. 8 | Pan | Anodized Aluminum | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 3/4" | 1/2" | 1/2" | 1/4" | No | 16 | 3" | No. 8 | Pan | Anodized Aluminum | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60" | 3/4" | 1/2" | 1/2" | 1/4" | No | 20 | 3" | No. 10 | Pan | Anodized Aluminum | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 72" | 3/4" | 1/2" | 1/2" | 1/4" | No | 24 | 3" | No. 10 | Pan | Anodized Aluminum | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96" | 3/4" | 1/2" | 1/2" | 1/4" | No | 32 | 3" | No. 10 | Pan | Anodized Aluminum | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120" | 3/4" | 1/2" | 1/2" | 1/4" | No | 40 | 3" | No. 10 | Pan | Anodized Aluminum | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

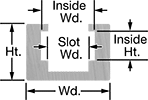

Metric Single-Profile Straight T-Tracks

|  |

Inside, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Wd., mm | Ht., mm | Width | Height | Material | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 mm Wide Slot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 600 | 17 | 12.25 | 10.5 | 4 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,200 | 17 | 12.25 | 10.5 | 4 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm Wide Slot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 600 | 18 | 15.25 | 11.5 | 5.5 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,200 | 18 | 15.25 | 11.5 | 5.5 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm Wide Slot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 600 | 21.5 | 19.75 | 15 | 7.5 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,200 | 21.5 | 19.75 | 15 | 7.5 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm Wide Slot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 600 | 23.5 | 22.25 | 17 | 7.5 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,200 | 23.5 | 22.25 | 17 | 7.5 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm Wide Slot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 600 | 26.5 | 25.75 | 20 | 8.5 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,200 | 26.5 | 25.75 | 20 | 8.5 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 mm Wide Slot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 600 | 30.5 | 28.75 | 24 | 10 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,200 | 30.5 | 28.75 | 24 | 10 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18 mm Wide Slot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 600 | 37.5 | 36.25 | 31 | 13 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,200 | 37.5 | 36.25 | 31 | 13 | Anodized Aluminum | DIN 650 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

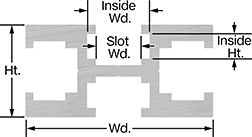

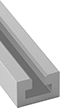

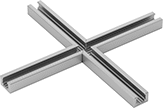

Single-Profile Perpendicular T-Tracks

|  |  |

Inside | Mounting Holes | For Mounting Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | Width | Height | Mounting Fasteners Included | Number of | Center-to-Center | Size | Head Style | Material | No. of Pieces | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Wide Slot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 3/4" | 1/2" | 1/2" | 1/4" | No | 2 | 2" | No. 6 | Pan | Anodized Aluminum | 4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

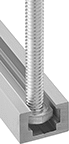

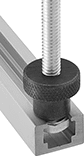

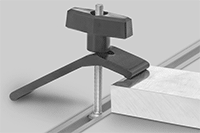

Hold-Down Clamps

|

For Max. Workpiece Thk. | Lg. | Wd. | Material | Each | |||

|---|---|---|---|---|---|---|---|

| 2 1/2" | 4 1/4" | 1" | Steel | 0000000 | 00000 | ||

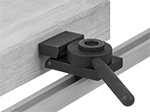

Cam Clamps

|

Lg. | Wd. | Material | Each | |||

|---|---|---|---|---|---|---|

| 1 3/8" | 2 3/16" | Steel | 0000000 | 000000 | ||

Quick-Change Fixture Plates

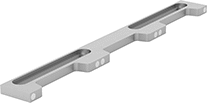

Mounting Rails

Magnetic Mount | Bolt-On Mount | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Max. Magnetic Pull, lbf | No. of Mounting Edges | Mounting Fasteners Included | No. of Mounting Slots | Mounting Slot Lg. | Mounting Slot Wd. | Material | Each | |||

| 18" | 2" | 1/2" | 3.5 | 3 | No | 2 | 5 7/16" | 1/2" | Anodized Aluminum | 0000000 | 0000000 | ||

| 30" | 2" | 1/2" | 3.5 | 5 | No | 6 | 3 1/8" | 1/2" | Anodized Aluminum | 0000000 | 000000 | ||

| 540 mm | 50 mm | 13 mm | 3.5 | 3 | No | 3 | 120 mm | 13 mm | Anodized Aluminum | 0000000 | 000000 | ||

| 720 mm | 50 mm | 13 mm | 3.5 | 4 | No | 6 | 68 mm | 13 mm | Anodized Aluminum | 0000000 | 000000 | ||