How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Standard-Wall Butt-Weld Stainless Steel Unthreaded Pipe Fittings

Also known as Schedule 40 fittings, these have thicker walls than our thin-wall stainless steel unthreaded butt-weld fittings. They have beveled ends that, when flush to pipe, create a trough for a strong weld that permits maximum flow.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

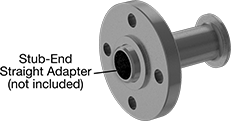

Stub-end straight adapters are used with flanges. Slide a flange onto the stub end and weld the stub end to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily, which creates an access point for frequent cleaning and inspecting.

- For Use With: Air, Natural Gas, Oil, Water

- Specifications Met: ASME B16.9, ASTM A403, MSS SP-43

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

Thin-Wall Butt-Weld Stainless Steel Unthreaded Pipe Fittings

Also known as Schedule 10 fittings, these are thin and lightweight. They have beveled ends that, when flush to pipe, create a trough for a strong weld that permits maximum flow.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Stub-end straight adapters are used with flanges. Slide a flange onto the stub end and weld the stub end to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily, which creates an access point for frequent cleaning and inspecting.

- For Use With: Air, Natural Gas, Oil, Water

- Specifications Met: ASME B16.9, ASTM A403, MSS SP-43

- Pipe: Use Schedule 10 stainless steel

FM-Approved Low-Pressure Cast Iron Unthreaded Pipe Flanges

- For Use With: Air, Diesel Fuel, Gasoline, Natural Gas, Oil, Steam, Water

- Pressure Class: 125

- Specifications Met: ASME B1.20.1, ASME B16.1, ASTM A126, FM Approved

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Class 125 or 150 iron and steel

FM-approved for fire protection applications, these flanges are cast iron, so they're brittle and can be quickly opened by hitting them with a sledge hammer. Bolt them together with a gasket (not included) to create an access point within a low-pressure pipe line. All are cap flanges, which are also known as blind flanges. Use them in noncorrosive environments.

Bolt Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

| 3 1/2 | 8 1/2" | 5/8" | 3/4" | 8 | 7" | 200 psi @ 72° F | 165 psi @ 300° F | 0000000 | 0000000 |

Standard-Wall Butt-Weld Steel Unthreaded Pipe Fittings

Butt-weld fittings allow for a smooth connection that provides maximum flow. They have beveled ends that, when flush to pipe, create a trough for a strong, permanent weld. Fittings are also known as Schedule 40. They are for use in noncorrosive environments.

Stub-end straight adapters are used with flanges. Slide a flange onto the stub end and weld the stub end to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily, which creates an access point for frequent cleaning and inspecting.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASTM A234, ASME B16.9

- Pipe Nipples and Pipe: Use Schedule 40 Steel

- Flanges: Use Class 150 Steel

Thick-Wall Butt-Weld Steel Unthreaded Pipe Fittings

With thicker, stronger walls than our standard-wall butt-weld pipe fittings, these fittings stand up to your high strength applications. Weld them flush against pipe for a smooth connection that permits maximum flow. These fittings have beveled ends that create a trough for a leak-resistant, permanent weld. Made of steel, they’re for use in noncorrosive environments.

Stub-end straight adapters are used with flanges. Slide a flange onto the stub end and weld the stub end to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily, which creates an access point for frequent cleaning and inspecting. Bolt flanges together with a gasket.

Extreme-Pressure Steel Unthreaded Pipe Flanges

For excellent strength in extreme-pressure applications, choose these heavy duty Pressure Class 1500 flanges. Bolt two same-size flanges together with a gasket (sold separately) to create an access point in a pipe line. They are for noncorrosive environments.

Butt-weld flanges are also known as weld-neck flanges; the flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld.

Slip-on weld flanges have no internal stop; slide a pipe through the flange and weld on both sides.

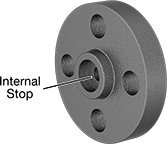

Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through.

Cap flanges are also known as blind flanges.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class : 1500

- Specifications Met: MSS SP-6, MSS SP-25, ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use Class 6000 steel

Bolt Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Wall Thick. | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | For Pipe Schedule | Each | |

| 2 | 32 | 0.218" | 8 1/2" | 7/8" | 1" | 8 | 6 1/2" | 3,700 psi @ 72° F | 3,200 psi @ 300° F | 80 | 0000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class : 1500

- Specifications Met: ASME B16.5, ASTM A105, MSS SP-25, MSS SP-6

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use Class 6000 steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | For Pipe Schedule | Each | |

| 2 | 32 | 8 1/2" | 7/8" | 1" | 8 | 6 1/2" | 3,700 psi @ 72° F | 3,200 psi @ 300° F | Any | 0000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class : 1500

- Specifications Met:

3 and 4 Pipe Sizes: ASTM A105

All other sizes: ASME B16.5, ASTM A105, MSS SP-25, MSS SP-6 - Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use Class 6000 steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | For Pipe Schedule | Each | |

| 2 | 32 | 8 1/2" | 7/8" | 1" | 8 | 6 1/2" | 3,700 psi @ 72° F | 3,200 psi @ 300° F | 80 | 0000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class : 1500

- Specifications Met: MSS SP-6, MSS SP-25, ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use Class 6000 steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | For Pipe Schedule | Each | |

| 2 | 32 | 8 1/2" | 7/8" | 1" | 8 | 6 1/2" | 3,700 psi @ 72° F | 3,200 psi @ 300° F | Any | 0000000 | 0000000 |

Low-Pressure Steel Threaded Pipe Flanges

Use these flanges for low-pressure applications in noncorrosive environments. Bolt two flanges of the same size together with a gasket (sold separately) to create an access point within a line.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met:

NPT: ASME B16.5, ASTM A105, MSS SP-25

BSPT: ASTM A105 - Fittings: Use Class 125 or 150 iron and steel

- Pipe Nipples and Pipe: Use Schedule 40 steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | ||||||||||

| 3 1/2 | 8 1/2" | 5/8" | 3/4" | 8 | 7" | 285 psi @ 72° F | 230 psi @ 300° F | Steel | 000000000 | 0000000 |

High-Pressure Steel Threaded Pipe Flanges

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 1500

- Specifications Met:

1/2 to 2 Pipe Sizes: ASME B16.5, ASTM A105, MSS SP-25, MSS SP-6

All other sizes: ASTM A105 - Pipe Nipples and Pipe: Use Schedule 160 or XXH steel

- Fittings: Use Class 3000 or 6000 iron and steel

Also known as Pressure Class 1500 flanges, these have the strength to handle high pressures. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Flanges are for use in noncorrosive environments.

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | |||||||||||

| 2 | 32 | 8 1/2" | 7/8" | 1" | 8 | 6 1/2" | 3,700 psi @ 72° F | 3,200 psi @ 300° F | Steel | 0000000 | 0000000 |