How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Selecting and Measuring Expansion Joints

For information about selecting pipe size, see Selecting and Measuring Pipe & Fittings.

More

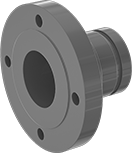

High-Purity Polypropylene Pipe Flanges for Corrosive Chemicals

- For Use With: Deionized Water, Drinking Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Solvents

- Pressure Class: 150

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2837, ASTM D4101, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.3297, ISO 7279, NSF/ANSI 61

- Pipe Nipples and Pipe: Use SDR 11 Polypropylene Plastic

- Fittings: Use Polypropylene Plastic

The inside of these flanges won’t leach contaminants into your line or accumulate particles—they’re polished to an ultra-smooth 12 Ra finish, which also makes them easy to clean. Made of polypropylene, they resist organic solvents, acids, and alkalis better than CPVC pipe flanges. Bolt two same-size flanges together with a gasket (not included) to create an access point in your line. These flanges meet NSF/ANSI 61 for use with drinking water, and they’re FDA compliant for direct contact with food. They also meet ASTM requirements for material and performance, and ISO requirements for dimensions.

Also known as lap-joint flanges, they connect to pipe with stub-end straight adapters (not included). Slide the stub end adapter into your flange and weld to your pipe with socket fusion. Since the flange isn’t welded to the pipe, it can be disconnected easily for cleaning and inspecting.

Flanges | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bolt Hole | Adapters | |||||||||||

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Material | Color | Max. Pressure | Each | Each | ||

Fixed Flanges, Stub End × Flanged | ||||||||||||

| 1/2 | 3 5/8" | 1/2" | 5/8" | 4 | 2 3/8" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 0000000 | 000000 | 00000000 | 000000 |

| 3/4 | 4 1/8" | 1/2" | 5/8" | 4 | 2 3/4" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 0000000 | 00000 | 00000000 | 00000 |

| 1 | 4 3/8" | 1/2" | 5/8" | 4 | 3 1/8" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 0000000 | 00000 | 00000000 | 00000 |

| 1 1/2 | 5 1/4" | 1/2" | 5/8" | 4 | 3 7/8" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 0000000 | 00000 | 00000000 | 00000 |

| 2 | 6 1/4" | 5/8" | 3/4" | 4 | 4 3/4" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 0000000 | 000000 | 00000000 | 00000 |

High-Purity Polypropylene Pipe Fittings for Corrosive Chemicals

The inside of these fittings won’t leach contaminants into your line or accumulate particles—they’re polished to an ultra-smooth 12 Ra finish, which also makes them easy to clean. Made of polypropylene, they resist organic solvents, acids, and alkalis better than CPVC fittings. These fittings meet NSF/ANSI 61 for use with drinking water, and they’re FDA compliant for direct contact with food. They also meet ASTM requirements for material and performance, and ISO requirements for dimensions.

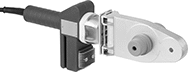

Connect them to pipe with socket fusion welding for a strong, permanent bond. Use a socket fusion tool with a heater bushing (sold separately) that matches your pipe size.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Deionized Water, Drinking Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2837, ASTM D4101, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.3297, ISO 7279, NSF/ANSI 61

- Pipe Nipples and Pipe: Use SDR 11 Polypropylene Plastic

- Flanges: Use Polypropylene Plastic

Stub-end straight adapters connect flanges to pipe. Slide the straight end into a flange and fuse the stub end to the pipe. Since the flange isn’t fused to the pipe, it can be disconnected easily for cleaning and inspecting.

Adapters | Flanges | |||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Wall Thick. | Material | Color | Max. Pressure | Each | Each | ||

| 1/2 | 0.119" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 | 0000000 | 000000 |

| 3/4 | 0.138" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 1 | 0.138" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 1 1/2 | 0.195" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 2 | 0.178" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 00000 | 0000000 | 000000 |

- For Use With: Deionized Water, Drinking Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2837, ASTM D4101, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.3297, ISO 7279, NSF/ANSI 61

- Seal Material: See table

- Seat Material: PTFE Plastic

Add a ball valve to control the flow in your line.

| Pipe Size | Flow Coefficient (Cv) | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Color | Max. Pressure | Each | |

EPDM Rubber Seal | ||||||||

|---|---|---|---|---|---|---|---|---|

Polypropylene Plastic | ||||||||

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 0000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

Viton® Fluoroelastomer Rubber Seal | ||||||||

Polypropylene Plastic | ||||||||

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| Each | ||

| 00000000 | 0000000 |

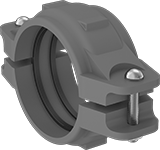

Easy-Access CPVC Pipe Flanges for Chemicals

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Sodium Hydroxide, Sulfuric Acid (80%), Water

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D1784

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

The grooved ends on these flanges connect to pipe with a clamp, so you can access your chemical process line for routine maintenance. They are also known as Victaulic flanges. Bolt two same-size flanges together with a gasket (sold separately). Flanges are CPVC, which has excellent chemical resistance to withstand a variety of salt solutions, acids, and other harsh substances. They are comparable to Corzan. Flanges meet ASTM D1784 specifications and testing requirements for material quality.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

| Pipe Size | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Each | |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | CPVC Plastic | Light Gray | 150 psi @ 72° F | 0000000 | 0000000 |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | CPVC Plastic | Light Gray | 150 psi @ 72° F | 0000000 | 000000 |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | CPVC Plastic | Light Gray | 150 psi @ 72° F | 0000000 | 000000 |

Clamp connectors let you connect CPVC grooved-end pipe fittings and pipe.

| For Pipe Size | For Pipe OD | Material | Color | Gasket Material | Max. Pressure | Specifications Met | Each | |

| 2 | 2 3/8" | Enamel-Coated Iron | Orange | EPDM Rubber | 300 psi @ 72° F | ASTM D1784, ASTM F441 | 0000000 | 000000 |

| 3 | 3 1/2" | Enamel-Coated Iron | Orange | EPDM Rubber | 300 psi @ 72° F | ASTM D1784, ASTM F441 | 0000000 | 00000 |

| 4 | 4 1/2" | Enamel-Coated Iron | Orange | EPDM Rubber | 300 psi @ 72° F | ASTM D1784, ASTM F441 | 0000000 | 000000 |

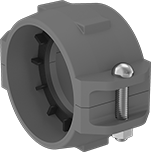

Clamp adapters let you connect CPVC grooved-end pipe fittings and pipe to metal grooved-end pipe fittings and pipe.

Clamp reducers allow you to connect CPVC grooved-end pipe fittings and pipe and transition from a larger pipe size to a smaller pipe size.

| For Pipe Size | For Pipe OD | Material | Color | Gasket Material | Max. Pressure | Specifications Met | Each | |

| 3 × 2 | 3 1/2" × 2 3/8" | Enamel-Coated Iron | Orange | EPDM Rubber | 300 psi @ 72° F | ASTM D1784, ASTM F441 | 0000000 | 000000 |

| 4 × 2 | 4 1/2" × 2 3/8" | Enamel-Coated Iron | Orange | EPDM Rubber | 300 psi @ 72° F | ASTM D1784, ASTM F441 | 0000000 | 000000 |

| 4 × 3 | 4 1/2" × 3 1/2" | Enamel-Coated Iron | Orange | EPDM Rubber | 300 psi @ 72° F | ASTM D1784, ASTM F441 | 0000000 | 000000 |

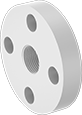

High-Temperature PTFE Pipe Flanges for Chemicals

- For Use With: Deionized Water, Hydrochloric Acid, Solvents

- Temperature Range: -450° to 550° F

- Specifications Met: ASTM D1710

- Pipe Nipples and Pipe: Use Schedule 80 PTFE Plastic

- Fittings: Use Schedule 80 PTFE Plastic

Made of PTFE, these flanges can handle a wider temperature range than any of our other plastic pipe flanges for chemicals. They have the chemical resistance to stand up to acid and solvents. Also known as Pressure Class 150 flanges, they have thick, strong walls for heavy duty industrial applications. The material won’t leach contaminates into the line, so these flanges are commonly used in high-purity processes, such as semiconductor and clean room applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. When connecting to pipe, apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the flange, then wrench-tighten one to two turns. Flanges meet ASTM D1710 specifications and testing requirements for material quality.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

| Pipe Size | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Each | |

Fixed Flanges, Female Threaded × Flanged | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

NPT Threads | ||||||||||

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | PTFE Plastic | White | 60 psi @ 72° F | 000000000 | 0000000 |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | PTFE Plastic | White | 50 psi @ 72° F | 000000000 | 000000 |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | PTFE Plastic | White | 35 psi @ 72° F | 000000000 | 000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

High-Purity PVDF Pipe Fittings for Corrosive Chemicals

Made of PVDF that’s finished to a 12 Ra smoothness, these fittings handle some of the harshest chemicals without leaching contaminants into your line. They won’t accumulate particles and are easy to clean, thanks to their smoothness. Comparable to Kynar, these fittings handle most organic solvents that would dissolve CPVC, and chlorine or nitric acid that would weaken polypropylene. You can use them at higher temperatures than CPVC and polypropylene. These fittings meet UL 94 V-0 and FM standards for flame retardance. They’re also FDA compliant for direct contact with food, and they meet ASTM requirements for dimensions and tolerances.

Connect them to pipe with socket fusion welding for a strong, permanent bond. Use a socket fusion tool with a heater bushing (sold separately) that matches your pipe size.

Adapter

with Flange

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3261, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Pipe Nipples and Pipe: Use SDR 21 PVDF Plastic

- Flanges: Use Polypropylene Plastic

Stub-end straight adapters connect flanges to pipe. Slide the straight end into a flange and fuse the stub end to the pipe. Since the flange isn’t fused to the pipe, it can be disconnected easily for cleaning and inspecting.

Adapters | Flanges | |||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Wall Thick. | Material | Color | Max. Pressure | Each | Each | ||

| 1/2 | 0.138" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 3/4 | 0.158" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 | 0000000 | 00000 |

| 1 | 0.177" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 | 0000000 | 00000 |

| 1 1/2 | 0.217" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 | 0000000 | 00000 |

| 2 | 0.256" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3222, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Seal Material: Viton® Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

Add a ball valve to control the flow in your line.

| Pipe Size | Flow Coefficient (Cv) | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Color | Max. Pressure | Each | |

PVDF Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | White | 230 psi @ 72° F | 0000000 | 0000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | White | 230 psi @ 72° F | 0000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | White | 230 psi @ 72° F | 0000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | White | 230 psi @ 72° F | 0000000 | 00000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | White | 230 psi @ 72° F | 0000000 | 00000000 |

| Each | ||

| 00000000 | 0000000 |

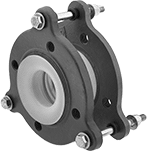

Chemical-Resistant Expansion Joints with Flanged Ends

- For Use With: Coolant, Hydrochloric Acid, Water

- Temperature Range: -0° to 400° F

- Maximum Pressure: See table

- Maximum Vacuum: 29 in. of Hg @ 72° F

The PTFE body on these expansion joints has a super-smooth surface that stands up to corrosive chemicals. Joints have a triple-bulb design that provides excellent vibration absorption, reducing stress on your piping system. The flanges mate with a same-size flat-surface Class 150 flange without the need for a gasket. Limit rods are attached to the flanges to prevent overextension.

Distance | Threaded Bolt Holes | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flange OD | Pipe Size | Lg. | No. of Bolt Holes | Compression | Expansion | Offset | Max. Pressure | Expansion Joint Type | Flange Material | Bolt Hole Thread Size | Each | |

Ultra-Corrosion-Resistant Coated PTFE Plastic | ||||||||||||

| 5" | 1 1/2 | 2" | 4 | 1/2" | 1/2" | 1/4" | 130 psi @ 72° F | Triple Bulb | Iron | 1/2"-13 | 0000000 | 0000000 |

| 6" | 2 | 2 3/4" | 4 | 3/4" | 3/4" | 3/8" | 130 psi @ 72° F | Triple Bulb | Iron | 5/8"-11 | 0000000 | 000000 |

| 7" | 2 1/2 | 3 3/16" | 4 | 3/4" | 3/4" | 3/8" | 130 psi @ 72° F | Triple Bulb | Iron | 5/8"-11 | 0000000 | 000000 |

| 7 1/2" | 3 | 3 5/8" | 4 | 1" | 1" | 1/2" | 130 psi @ 72° F | Triple Bulb | Iron | 5/8"-11 | 0000000 | 00000000 |

| 9" | 4 | 3 5/8" | 8 | 1" | 1" | 1/2" | 130 psi @ 72° F | Triple Bulb | Iron | 5/8"-11 | 0000000 | 00000000 |

| 11" | 6 | 4" | 8 | 1 1/8" | 1 1/8" | 9/16" | 130 psi @ 72° F | Triple Bulb | Iron | 3/4"-10 | 0000000 | 00000000 |

| 13 1/2" | 8 | 6" | 8 | 1 1/8" | 1 1/8" | 9/16" | 120 psi @ 72° F | Triple Bulb | Iron | 3/4"-10 | 0000000 | 00000000 |