How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

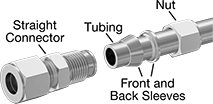

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

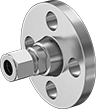

Fittings with flange end connect to another same-size flange with a gasket (sold separately) to create an access point in your line. They are also known as Pressure Class 150 flanges.

For Tube | Bolt Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Flange OD | Material | Max. Pressure | Temp. Range, °F | Bolt Circle Dia. | Dia. | No. of | Bolts Included | Specifications Met | Each | |

| 1/2" | 0.035" | 1/2 | 3 1/2" | 316 Stainless Steel | 250 psi @ 72° F | -420° to 1200° | 2 3/8" | 5/8" | 4 | No | ASME B16.5 | 00000000 | 0000000 |

| 1/2" | 0.035" | 1 | 4 1/4" | 316 Stainless Steel | 250 psi @ 72° F | -420° to 1200° | 3 1/8" | 5/8" | 4 | No | ASME B16.5 | 00000000 | 000000 |

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

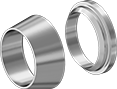

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each front sleeve, back sleeve, and nut is made of 316 stainless steel for excellent corrosion resistance. Five sets of sleeves and nuts come on each dispenser. Sleeves are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sets with Dispenser | |||||||||||

| 1/2" | 0.035" | 316 Stainless Steel | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 2,000 psi @ 72° F | 0000000 | 000000 |

PTFE sleeves are plastic instead of stainless steel, so they won’t damage tubing.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/2" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Tube Support Style | Temp. Range, °F | Each | |

| 1/2" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 000000 |

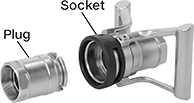

Minimal-Spill Push-and-Turn Hose Couplings for Chemicals

Quickly connect and disconnect hose lines used with a variety of chemicals, from adhesives to isopropyl alcohol and ink. Any part of these couplings that contacts fluid is made from 316 stainless steel, C-276 Hastelloy, PTFE, or fluoroelastomer to withstand the chemicals in your line. Tough enough to handle frequent use, these couplings are designed to be virtually spill free. Also known as dry disconnects and double-shut off couplings, both the plug and the socket have a shut-off valve that stops the flow of liquids when they’re separated. To connect, push the plug into the socket and lock with a quarter turn. The socket swivels, so you won’t have to twist your hose to attach the plug. It also has a rubber lip and large handles to prevent damage if it’s dropped.

A complete coupling consists of a plug and a socket (both sold separately). They’re compatible with MannTek, Avery Hardoll, Todo-matic, and other dry-disconnect couplings that meet NATO standard STANAG 3756.

Aluminum couplings are lighter in weight than stainless steel and have good corrosion resistance.

316 stainless steel couplings have excellent corrosion resistance.

- For Use With:

Aluminum: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Varnish, Vegetable Oil

316 Stainless Steel: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil - Maximum Pressure:

Aluminum: 230 psi @ 72° F

316 Stainless Steel: 360 psi @ 72° F - Temperature Range: -15° to 400° F

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Plug OD | Pipe Size | Flange OD | Flanged Connection Surface | Pressure Class | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Each | |

Aluminum | ||||||||||

| 2 3/4" | 2 | 6" | Flat | 150 | 5/8" | 3/4" | 4 | 4 3/4" | 0000000 | 0000000 |

| 4 11/16" | 3 | 7 1/2" | Flat | 150 | 5/8" | 3/4" | 4 | 6" | 0000000 | 000000 |

316 Stainless Steel | ||||||||||

| 2 3/4" | 2 | 6" | Raised | 150 | 5/8" | 3/4" | 4 | 4 3/4" | 0000000 | 000000 |

| 4 11/16" | 3 | 7 1/2" | Raised | 150 | 5/8" | 3/4" | 4 | 6" | 0000000 | 00000000 |

- For Use With: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil

- Maximum Pressure: 360 psi @ 72° F

- Temperature Range: -15° to 400° F