Press-Connect Fittings for Copper Tubing

- For Use With: Drinking Water

- Maximum Pressure: Fittings compatible with Viega ProPress or Viega ProPress XL-C: 200 psi @ 72° F

Fittings compatible with Viega Pex or Viega PureFlow Press: 100 psi @ 72° F - Temperature Range: 0° to 250° F

- Tubing: Fittings compatible with Viega ProPress or Viega ProPress XL-C: Use with K, M, L copper

Fittings compatible with Viega Pex or Viega PureFlow Press: Use with hard polyethylene plastic - Specifications Met: See table

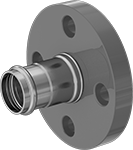

Crimp these fittings to copper tubing with a crimping tool (sold separately). An O-ring on the inside of the fitting creates a leak-tight connection that doesn’t require heat or soldering. They are comparable to Viega ProPress fittings. Fittings have good corrosion resistance. They meet NSF/ANSI safety standards for use with drinking water systems.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

Straight adapters with flanged end bolt to equipment or other flanged connections found on pumps and valves to create a convenient access point.

Bolt Hole | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Copper Tube Size | For Tube OD | Pipe Size | Flange OD | Bolt Circle Dia. | Dia. | No. of | For Bolt Dia. | Bolts Included | Lg. | Material | Flange Material | Compatible With | Specifications Met | Each | |

| 2 1/2 | 2 5/8" | 2 1/2 | 7 3/32" | 5 33/64" | 3/4" | 4 | 5/8" | No | 2 51/64" | Copper | Powder-Coated Steel | Viega ProPress XL-C | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 0000000 |

| 3 | 3 1/8" | 3 | 7 31/64" | 5 63/64" | 3/4" | 4 | 5/8" | No | 3 11/64" | Copper | Powder-Coated Steel | Viega ProPress XL-C | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 000000 |

| 4 | 4 1/8" | 4 | 9 1/16" | 7 33/64" | 3/4" | 8 | 5/8" | No | 3 21/32" | Copper | Powder-Coated Steel | Viega ProPress XL-C | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 000000 |

Rings for copper tube sizes 2 ½ to 4 include a jaw actuator. Clip the rings around the fitting and use the jaw actuator and crimping tool (sold separately) to press the open ends together.

| For Copper Tube Size | For Tube OD | Includes | Compatible With | Each | |

| 2 1/2, 3, 4 | 2 5/8", 3 1/8", 4 1/8" | Three Rings (2 1/2-4 Copper Tube Size) One Ring Actuator Jaw | Viega ProPress XL-C | 00000000 | 000000000 |

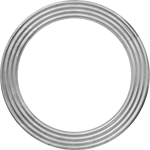

High-Temperature Steam-Resistant Metallic Pipe Gaskets

Made of 110 copper, these gaskets handle steam applications up to 600° F. They are electrically conductive and resist water, Freon, and fuel oil. The metal construction provides structural strength. These gaskets can be used with both flat-surface and raised-surfaces pipe flanges; they fit the surface inside the bolt holes and do not interfere with the bolt connection. Gaskets are compatible with low-pressure pipe flanges; all gasket specifications are sized to meet ANSI standards.

Corrugated gaskets conform to rough and uneven surfaces when put under low pressure for a tight seal.

Smooth gaskets can withstand higher pressure than the corrugated gaskets.

| For Pipe Size | ID | OD | Thick. | Max. Pressure, psi | Max. Temperature, °F | Material | Each | |

For ANSI Class 150 | ||||||||

|---|---|---|---|---|---|---|---|---|

Corrugated | ||||||||

| 1 | 1 1/4" | 2 5/8" | 0.040" | 500 | 600° | 110 Copper | 0000000 | 00000 |

| 1 1/2 | 1 29/32" | 3 3/8" | 0.040" | 500 | 600° | 110 Copper | 0000000 | 0000 |

| 2 | 2 3/4" | 4 1/8" | 0.040" | 500 | 600° | 110 Copper | 0000000 | 0000 |

| 2 1/2 | 3 1/4" | 4 7/8" | 0.040" | 500 | 600° | 110 Copper | 0000000 | 00000 |

| 3 | 4" | 5 3/8" | 0.040" | 500 | 600° | 110 Copper | 0000000 | 00000 |

| 4 | 5" | 6 7/8" | 0.040" | 500 | 600° | 110 Copper | 0000000 | 00000 |

| 6 | 7 3/16" | 8 3/4" | 0.040" | 500 | 600° | 110 Copper | 0000000 | 00000 |

Smooth | ||||||||

| 1 | 1 1/4" | 2 5/8" | 0.063" | 1,500 | 600° | 110 Copper | 0000000 | 0000 |

| 1 1/2 | 1 29/32" | 3 3/8" | 0.063" | 1,500 | 600° | 110 Copper | 0000000 | 00000 |

| 2 | 2 3/4" | 4 1/8" | 0.063" | 1,500 | 600° | 110 Copper | 0000000 | 00000 |

| 2 1/2 | 3 1/4" | 4 7/8" | 0.063" | 1,500 | 600° | 110 Copper | 0000000 | 00000 |

| 3 | 4" | 5 3/8" | 0.063" | 1,500 | 600° | 110 Copper | 0000000 | 00000 |

| 4 | 5" | 6 7/8" | 0.063" | 1,500 | 600° | 110 Copper | 0000000 | 00000 |

| 6 | 7 3/16" | 8 3/4" | 0.063" | 1,500 | 600° | 110 Copper | 0000000 | 00000 |