How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

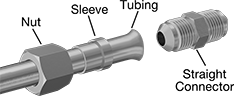

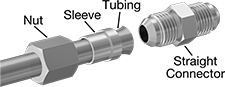

37° Flared Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

- Temperature Range: See table

| For Tube OD | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPTF Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | -60° to 400° | 000000000 | 00000 |

| 1/4" | 1/4 | Zinc-Plated Steel | 5,000 psi @ 72° F | -60° to 400° | 000000000 | 0000 |

| 5/16" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | -60° to 400° | 000000000 | 0000 |

| 3/8" | 1/4 | Zinc-Plated Steel | 5,000 psi @ 72° F | -60° to 400° | 000000000 | 0000 |

| 3/8" | 3/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | -60° to 400° | 000000000 | 0000 |

| 1/2" | 3/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | -60° to 400° | 000000000 | 0000 |

| 1/2" | 1/2 | Zinc-Plated Steel | 4,000 psi @ 72° F | -60° to 400° | 000000000 | 0000 |

| 5/8" | 1/2 | Zinc-Plated Steel | 3,000 psi @ 72° F | -60° to 400° | 000000000 | 0000 |

| 3/4" | 3/4 | Zinc-Plated Steel | 3,300 psi @ 72° F | -60° to 400° | 000000000 | 0000 |

| 1" | 1 | Zinc-Plated Steel | 3,500 psi @ 72° F | -60° to 400° | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | |||||

|---|---|---|---|---|---|

| 1/4" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 00000 |

| 1/4" | 1/4 | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 0000 |

| 5/16" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 00000 |

| 3/8" | 1/4 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 3/8" | 3/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 1/2" | 3/8 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 00000 |

| 1/2" | 1/2 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 5/8" | 1/2 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 00000 |

| 3/4" | 3/4 | Zinc-Plated Steel | 2,500 psi @ 72° F | 000000000 | 00000 |

| 1" | 1 | Zinc-Plated Steel | 2,000 psi @ 72° F | 000000000 | 00000 |

- Temperature Range: NPT: -65° to 400° F

NPTF and BSPT: -60° to 400° F

Metric and BSPP with O-Rings: -30° to 200°F

BSPP with Washers: -20° to 212° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | |||||

|---|---|---|---|---|---|

| 1/4" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 00000 |

| 1/4" | 1/4 | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 0000 |

| 1/4" | 3/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 1/4" | 1/2 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 5/16" | 1/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 5/16" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 0000 |

| 5/16" | 3/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 00000 |

| 3/8" | 1/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 3/8" | 1/4 | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 0000 |

| 3/8" | 3/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 0000 |

| 3/8" | 1/2 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 1/2" | 1/4 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 1/2" | 3/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 1/2" | 1/2 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 1/2" | 3/4 | Zinc-Plated Steel | 2,500 psi @ 72° F | 000000000 | 00000 |

| 1/2" | 1 | Zinc-Plated Steel | 2,000 psi @ 72° F | 000000000 | 00000 |

| 5/8" | 1/2 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 3/4" | 3/8 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 00000 |

| 3/4" | 1/2 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 00000 |

| 3/4" | 3/4 | Zinc-Plated Steel | 3,300 psi @ 72° F | 000000000 | 00000 |

| 1" | 1/2 | Zinc-Plated Steel | 2,500 psi @ 72° F | 000000000 | 00000 |

| 1" | 3/4 | Zinc-Plated Steel | 2,500 psi @ 72° F | 000000000 | 00000 |

| 1" | 1 | Zinc-Plated Steel | 3,500 psi @ 72° F | 000000000 | 00000 |

| 1 1/4" | 1 1/4 | Zinc-Plated Steel | 1,150 psi @ 72° F | 000000000 | 00000 |

| 1 1/2" | 1 1/2 | Zinc-Plated Steel | 1,000 psi @ 72° F | 000000000 | 00000 |

| 2" | 2 | Zinc-Plated Steel | 1,000 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | |||||

|---|---|---|---|---|---|

| 1/4" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | 000000000 | 000000 |

| 3/8" | 1/4 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 3/8" | 3/8 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 00000 |

| 1/2" | 3/8 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 00000 |

| 1/2" | 1/2 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 00000 |

| 5/8" | 1/2 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 00000 |

| 3/4" | 3/4 | Zinc-Plated Steel | 2,500 psi @ 72° F | 000000000 | 00000 |

| 1" | 1 | Zinc-Plated Steel | 2,000 psi @ 72° F | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

For Tube OD | |||||

|---|---|---|---|---|---|

| Inch | Metric, mm | Sleeve Material | Max. Pressure | Each | |

Inch Sleeves | |||||

| 1/4" | __ | Zinc-Plated Steel | 4,500 psi @ 72° F | 000000000 | 00000 |

| 5/16" | __ | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 000 |

| 3/8" | __ | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 000 |

| 1/2" | __ | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 5/8" | __ | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 3/4" | __ | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 1" | __ | Zinc-Plated Steel | 2,500 psi @ 72° F | 000000000 | 0000 |

| 1 1/4" | __ | Zinc-Plated Steel | 2,000 psi @ 72° F | 00000000 | 0000 |

| 1 1/2" | __ | Zinc-Plated Steel | 1,500 psi @ 72° F | 00000000 | 00000 |

Inch × Metric Sleeve Adapters | |||||

| 1/4" | 6 | Zinc-Plated Steel | 4,500 psi @ 72° F | 000000000 | 000 |

| 5/16" | 8 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 3/8" | 10 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 1/2" | 12 | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 5/8" | 14 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 5/8" | 16 | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 00000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1/4" | Zinc-Plated Steel | 4,500 psi @ 72° F | 000000000 | 00000 |

| 5/16" | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 3/8" | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 1/2" | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 0000 |

| 5/8" | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 3/4" | Zinc-Plated Steel | 3,000 psi @ 72° F | 000000000 | 0000 |

| 1" | Zinc-Plated Steel | 2,500 psi @ 72° F | 000000000 | 0000 |

| 1 1/4" | Zinc-Plated Steel | 2,000 psi @ 72° F | 00000000 | 00000 |

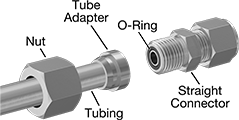

O-Ring Face Seal Fittings for Steel Tubing

- For Use With: Air, Hydraulic Fluid

- Temperature Range: -30° to 250° F, except BSPP fittings are -20° to 230° F

- Tubing: Use with seamless steel

- Specifications Met: SAE J1453

A tube adapter sits flush against the flat face of the fitting so you can slide the tubing and fitting sideways to disconnect in cramped spaces. Fittings are also known as zero-clearance fittings. To install, weld a tube adapter to the tubing with a brazing ring (sold separately), then mate the tube adapter to the fitting and screw on the nut. As the nut is tightened, the tube adapter compresses the O-ring, creating a strong seal. Fittings are zinc-plated steel for fair corrosion resistance. Nuts and tube adapters are sold separately.

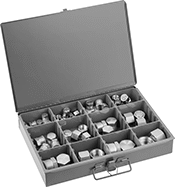

| Number of Pieces | Includes | Material | Max. Pressure | Each | |

| 62 | Plug for 1/4" OD Tubing (10 each) Plug for 3/8" OD Tubing (10 each) Plug for 1/2" OD Tubing (4 each) Plug for 5/8" OD Tubing (3 each) Plug for 3/4" OD Tubing (2 each) Plug for 1" OD Tubing (2 each) Cap for 1/4" OD Tubing (10 each) Cap for 3/8" OD Tubing (10 each) Cap for 1/2" OD Tubing (4 each) Cap for 5/8" OD Tubing (3 each) Cap for 3/4" OD Tubing (2 each) Cap for 1" OD Tubing (2 each) Metal Box | Zinc-Plated Steel | 6,000 psi @ 72° F | 00000000 | 0000000 |

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

- For Use With: See table

- Temperature Range: See table

| For Tube OD | Pipe Size | For Use With | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4" | 3/8 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 5,000 psi @ 72° F | -380° to 800° | 000000000 | 000000 |

| 1/4" | 1/2 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 5,000 psi @ 72° F | -380° to 800° | 000000000 | 00000 |

| 3/8" | 1/8 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 5,000 psi @ 72° F | -380° to 800° | 000000000 | 00000 |

| 3/8" | 1/2 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 5,000 psi @ 72° F | -380° to 800° | 000000000 | 00000 |

| 1/2" | 1/4 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 4,500 psi @ 72° F | -380° to 800° | 000000000 | 00000 |

| 1/2" | 3/4 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 4,500 psi @ 72° F | -380° to 800° | 000000000 | 000000 |

| 3/4" | 1/2 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 3,500 psi @ 72° F | -380° to 800° | 000000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

Plastic Push-to-Connect Tube Fittings for Chemicals

- For Use With: Inch: Alcohol, Hydrochloric Acid, Nitric Acid, Sodium Carbonate, Sulfuric Acid

Metric: Acetic Acid, Alcohol, Arsenic Acid, Benzoic Acid, Fluoboric Acid, Sodium Carbonate, Sulfuric Acid - Temperature Range: Inch: 0° to 270° F

Metric: 32° to 175° F - Tubing: Use with hard (Durometer 55D-60D) FEP plastic

Also known as instant fittings, these chemical-resistant plastic fittings connect to tubing with a push. An internal gripping ring holds the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. Use these fittings in low-pressure applications.

PVDF fittings offer excellent chemical resistance, and can be used with hydrochloric acid and nitric acid. They withstand temperatures up to 270° F, higher than other push-to-connect fittings for chemicals. They are produced in a clean room and are bagged individually to prevent dirt and moisture from contaminating the inside. PVDF is also known as Kynar.

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 1/4" | PVDF Plastic | Black | Gray | 300 psi @ 72° F | 00000000 | 000000 |

| For Tube OD (Push to Connect) | For Tube OD (Flared) | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 3/8" | 1/4" | PVDF Plastic | Black | Gray | 300 psi @ 72° F | 00000000 | 000000 |