About Backflow-Prevention Valves

More

About Actuated On/Off Valves

More

About Precision Flow-Adjustment Valves

More

About Flanged Flow-Adjustment Valves

More

About On/Off Valves

More

How to Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Precision Flow-Adjustment Valves with Yor-Lok Fittings for Chemicals

- Valve Type: Needle

- For Use With: Oil, Acetone, Air, Ammonia, Argon, Butane, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Gasoline, Helium, Isopropyl Alcohol, Kerosene, Krypton, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Soap Solutions, Sodium Hydroxide, Toluene, Xenon, Xylene

- Seal Material: PTFE Plastic

- Seat Material: 316 Stainless Steel

- Packing Material: PTFE Plastic

- Needle Material: 316 Stainless Steel

For extra gripping power and a strong seal, these valves have Yor-Lok fittings with two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. The 316 stainless steel body, seal and needle, and the PTFE seat and packing can withstand aggressive and corrosive solutions in chemical-processing applications. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control. Threads and a hex nut below the handle allow you to mount these valves in instrument panels. All have a nut that can be tightened to compress the packing if it leaks. Valves have bubble-tight soft seats that provide a tight seal when the valve is completely closed.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Panel Cutout Dia. | End-to-End Lg. | Each | |

316 Stainless Steel Body | |||||||

|---|---|---|---|---|---|---|---|

Yor Lok × Yor Lok | |||||||

| 1/4" | 0.56 | 7000 psi @ 400° F | -20° to 400° | 0.87" | 2 7/8" | 0000000 | 0000000 |

| 3/8" | 0.56 | 7000 psi @ 400° F | -20° to 400° | 0.87" | 2 7/8" | 0000000 | 000000 |

| 1/2" | 0.56 | 7000 psi @ 400° F | -20° to 400° | 0.87" | 3 1/8" | 0000000 | 000000 |

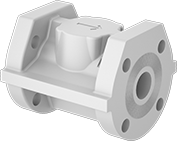

Flanged Flow-Adjustment Valves for Chemicals

With seats that can stand up to aggressive and corrosive solutions, these valves are often used in chemical-processing applications. They bolt to flanges for adjusting and regulating flow in flanged pipelines.

Wafer valves must be sandwiched between two flanges; they have tabs or unthreaded holes to help align the valve between the flanges.

Lug valves can be sandwiched between two flanges or bolted directly to a single flange for servicing one end of the pipeline without depressurizing the other side. They have threaded flange holes with a hole pattern that matches ANSI flanges of the same pipe size.

Lockable lever handles have 10 flow-adjustment positions. The handle can be fixed in place with a padlock (not included).

Wheel handles open and close with multiple turns, providing fully adjustable flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc:

Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene

316 Stainless Steel Disc:

Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid - Seat Material: Fluoroelastomer Rubber

- Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | For Max. Shackle Dia. | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—Painted Ductile Iron Disc | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 5/16" | 150, 125 | 6" | 4 3/4" | 4 | 3/4" | No | 115 | 200 psi @ 275° F | 10° to 275° | 1 3/4" | 000000000 | 0000000 |

| 2 1/2 | 5/16" | 150, 125 | 7" | 5 1/2" | 4 | 3/4" | No | 196 | 200 psi @ 275° F | 10° to 275° | 1 7/8" | 000000000 | 000000 |

| 3 | 5/16" | 150, 125 | 7 1/2" | 6" | 4 | 3/4" | No | 302 | 200 psi @ 275° F | 10° to 275° | 1 7/8" | 000000000 | 000000 |

| 4 | 5/16" | 150, 125 | 9" | 7 1/2" | 4 | 3/4" | No | 600 | 200 psi @ 275° F | 10° to 275° | 2 1/8" | 000000000 | 000000 |

| 5 | 5/16" | 150, 125 | 10" | 8 1/2" | 4 | 7/8" | No | 1,022 | 200 psi @ 275° F | 10° to 275° | 2 1/4" | 000000000 | 00000000 |

| 6 | 5/16" | 150, 125 | 11" | 9 1/2" | 4 | 7/8" | No | 1,579 | 200 psi @ 275° F | 10° to 275° | 2 1/4" | 000000000 | 00000000 |

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc:

Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene

316 Stainless Steel Disc:

Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid - Seat Material: Fluoroelastomer Rubber

- Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—Painted Ductile Iron Disc | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 150, 125 | 13 1/2" | 11 3/4" | 4 | 7/8" | No | 3,136 | 200 psi @ 275° F | 10° to 275° | 2 1/2" | 000000000 | 000000000 |

- Valve Type: Butterfly

- For Use With: See table

- Seat Material:

Ductile Iron Body: Fluoroelastomer Rubber

Cast Iron Body: PTFE-Lined Buna-N Rubber - Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

Ductile Iron Body—316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | For Use With | For Max. Shackle Dia. | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—Painted Ductile Iron Disc | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene | 5/16" | 150, 125 | 6" | 4 3/4" | 4 | 3/4" | No | 115 | 200 psi @ 275° F | 10° to 275° | 1 3/4" | 000000000 | 0000000 |

| 2 1/2 | Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene | 5/16" | 150, 125 | 7" | 5 1/2" | 4 | 3/4" | No | 196 | 200 psi @ 275° F | 10° to 275° | 1 7/8" | 000000000 | 000000 |

| 3 | Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene | 5/16" | 150, 125 | 7 1/2" | 6" | 4 | 3/4" | No | 302 | 200 psi @ 275° F | 10° to 275° | 1 7/8" | 000000000 | 000000 |

| 4 | Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene | 5/16" | 150, 125 | 9" | 7 1/2" | 8 | 3/4" | No | 600 | 200 psi @ 275° F | 10° to 275° | 2 1/8" | 000000000 | 000000 |

| 5 | Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene | 5/16" | 150, 125 | 10" | 8 1/2" | 8 | 7/8" | No | 1,022 | 200 psi @ 275° F | 10° to 275° | 2 1/4" | 000000000 | 00000000 |

| 6 | Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene | 5/16" | 150, 125 | 11" | 9 1/2" | 8 | 7/8" | No | 1,579 | 200 psi @ 275° F | 10° to 275° | 2 1/4" | 000000000 | 000000 |

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc:

Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene

316 Stainless Steel Disc:

Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid - Seat Material: Fluoroelastomer Rubber

- Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—Painted Ductile Iron Disc | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 150, 125 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | 3,136 | 200 psi @ 275° F | 10° to 275° | 2 1/2" | 000000000 | 000000000 |

Ultra-Chemical-Resistant Threaded On/Off Valves

The most chemical-resistant threaded valves we offer, these have a PTFE seal and an alloy body that can withstand extremely aggressive and corrosive chemicals, such as methyl ethyl ketone and toluene. They are standard port, so they slightly restrict flow.

Monel valves are more corrosion resistant than Alloy 20 valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Acetone, Air, Butane, Carbon Dioxide, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Kerosene, Methanol, Methyl Ethyl Ketone, Nitrogen, Propane, Soap Solutions, Sodium Hydroxide, Toluene, Water, Xylene

- Ball Material: Alloy 20 Stainless Steel

- Seal Material: PTFE Plastic

- Seat Material: PTFE Plastic

- Valve Type: Ball

- For Use With: Acetone, Air, Carbon Dioxide, Diesel Fuel, Gasoline, Kerosene, Methyl Ethyl Ketone, Nitrogen, Salt Water, Soap Solutions, Sodium Hydroxide, Toluene, Water, Xylene

- Ball Material: Monel

- Seal Material: PTFE Plastic

- Seat Material: PTFE Plastic

Easy-Maintenance Threaded On/Off Valves for Chemicals

- Valve Type: Ball

- For Use With: Carbon Dioxide, Citric Acid, Deionized Water, Ethanol, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Methanol, Methyl Ethyl Ketone, Phosphoric Acid, Salt Water, Sodium Hydroxide, Water

- Ball Material: Polypropylene Plastic

- Seal Material: See table

- Seat Material: PTFE Plastic

No need to remove these valves from your line to access their internal components—the three-piece bolted body comes apart. Ideal in chemical-processing applications, the seal and polypropylene body stand up to aggressive and corrosive solutions.

Valves with a lever handle give you more leverage than valves with T-handles, so you can quickly open and close them with ease. To limit access to your line, replace the handle with a locking handle (sold separately). Fix the handle in place using a padlock (not included) with a shackle diameter up to 19/64". Valves with a T-handle are more compact than valves with a lever handle, so they fit in tighter spots. They also resist accidental movement when snagged or bumped.

Valves with a cam-and-groove male plug quickly connect and disconnect medium- to large-diameter hose lines. Insert the plug end into a cam-and-groove female socket.

Valves with a fluoroelastomer seal fit snug even when surfaces are irregular, misaligned, or dirty. The seal compresses and conforms to create a tight, leakproof connection. Pick valves with a PTFE seal if you frequently need to open and close valves. The seal is slippery to reduce friction and prevent wear.

Full-port valves do not restrict flow. Standard-port valves slightly restrict flow.

Valves | Locking Handles | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Coupling Size | Plug OD | Max. Pressure | Temperature Range, °F | Seal Material | Port Type | End-to-End Lg. | Each | Each | ||

Black Polypropylene Plastic Body with Lever Handle | |||||||||||

NPT Female × NPT Female | |||||||||||

| 1/2 | __ | __ | 300 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 3 7/16" | 0000000 | 000000 | 000000 | 00 |

| 3/4 | __ | __ | 300 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 3 7/16" | 0000000 | 00000 | 000000 | 00 |

| 1 | __ | __ | 225 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Standard | 3 7/16" | 0000000 | 00000 | 000000 | 00 |

| 1 | __ | __ | 300 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 4 3/16" | 0000000 | 00000 | 000000 | 00 |

| 1 | __ | __ | 300 psi @ 70° F | 0° to 150° | PTFE Plastic | Full | 4 1/8" | 00000000 | 000000 | 000000 | 00 |

| 1 1/4 | __ | __ | 225 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 4 11/16" | 0000000 | 00000 | 00000000 | 000000 |

| 1 1/4 | __ | __ | 300 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Standard | 4 3/16" | 0000000 | 00000 | 00000000 | 00000 |

| 1 1/2 | __ | __ | 225 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 4 11/16" | 0000000 | 00000 | 00000000 | 00000 |

| 1 1/2 | __ | __ | 225 psi @ 70° F | 0° to 150° | PTFE Plastic | Standard | 4 5/8" | 00000000 | 000000 | 00000000 | 00000 |

| 2 | __ | __ | 150 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 5 3/8" | 00000000 | 00000 | 000000 | 00 |

| 2 | __ | __ | 225 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Standard | 4 11/16" | 0000000 | 00000 | 00000000 | 00000 |

| 2 | __ | __ | 225 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 5 1/2" | 0000000 | 00000 | 00000000 | 00000 |

| 3 | __ | __ | 200 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 6 3/8" | 0000000 | 000000 | 00000000 | 00000 |

| 3 | __ | __ | 225 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Standard | 6 1/16" | 0000000 | 000000 | 00000000 | 00000 |

| 4 | __ | __ | 100 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Standard | 7 7/8" | 0000000 | 000000 | 00000000 | 00000 |

NPT Male × Cam-and-Groove Male Plug | |||||||||||

| 2 | 2 | 2 7/16" | 150 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 8 1/4" | 00000000 | 00000 | 000000 | 00 |

| 2 | 2 | 2 7/16" | 225 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 8 1/8" | 00000000 | 00000 | 00000000 | 00000 |

Black Polypropylene Plastic Body with T-Handle | |||||||||||

NPT Female × NPT Female | |||||||||||

| 3/4 | __ | __ | 300 psi @ 70° F | 0° to 150° | Fluoroelastomer Rubber | Full | 3 3/8" | 00000000 | 00000 | 000000 | 00 |

Flanged On/Off Valves for Chemicals

Bolt these valves to ANSI flanges—they meet ASME dimensional standards. They have a plastic body and a seal that withstand aggressive and corrosive solutions in chemical-processing applications.

Glass-filled vinyl ester valves stand up to a wide variety of harsh acids and solvents. You can rely on them for repeated use, changes in pressure and flow rate, and hot and cold conditions.

Valves with a lockable lever handle can be fixed in place with a padlock (not included). They give you more leverage than short lever handles, so you can quickly open and close the valve with minimal effort.

Standard-port valves slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Oil, Phosphoric Acid, Salt Water, Soap Solutions, Toluene, Water, Xylene

- Ball Material: Glass-Filled Vinyl Ester

- Seal Material: PTFE Plastic

- Seat Material: PTFE Plastic

- Packing Material: PTFE Plastic

- For Flange Specifications Met: ASME B16.5, ASME B16.10

Bolts | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Dia. | Included | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | For Max. Shackle Dia. | Each | |

Flanged × Flanged | |||||||||||||||

| 1 | 150 | 4 1/4" | 3 1/8" | 4 | 5/8" | No | 45 | 250 psi @ 100° F | -50° to 215° | 29.9 | Standard | 5" | 5/16" | 0000000 | 0000000 |

| 1 1/2 | 150 | 5" | 3 7/8" | 4 | 5/8" | No | 115 | 250 psi @ 100° F | -50° to 215° | 29.9 | Standard | 6 1/2" | 1/4" | 00000000 | 000000 |

| 2 | 150 | 6" | 4 3/4" | 4 | 3/4" | No | 165 | 250 psi @ 100° F | -50° to 215° | 29.9 | Standard | 7" | 5/16" | 0000000 | 000000 |

| 3 | 150 | 7 1/2" | 6" | 4 | 3/4" | No | 350 | 250 psi @ 100° F | -50° to 215° | 29.9 | Standard | 8" | 5/16" | 0000000 | 00000000 |

| 4 | 150 | 9" | 7 1/2" | 4 | 3/4" | No | 540 | 150 psi @ 100° F | -50° to 215° | 29.9 | Standard | 9" | 1/4" | 00000000 | 00000000 |

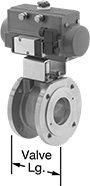

Flanged Air-Driven On/Off Valves for Chemicals

- Valve Type: Ball

- For Use With: Water, Oil, Air, Natural Gas, Propane, Butane, Acetone, Argon, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Helium, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Neon, Nitric Acid, Nitrogen, Oxygen, Salt Water, Soap Solutions, Steam, Xenon, Citric Acid, Krypton

- Ball Material: 316 Stainless Steel

- Seal Material : PTFE Plastic

- Seat Material: PTFE Plastic

- Actuator Housing Material: Aluminum

- Specifications Met: ASME B16.34

A 316 stainless steel body and a PTFE seal stand up to aggressive and corrosive solutions in chemical-processing applications. Their ball-valve design allows these valves to handle at least three times the flow of standard flanged valves. For faster actuation than motor-driven valves, they operate on compressed air. You must control the air to the actuator using either the included electric pilot valve or a manual on/off valve (not included). These valves automatically start and stop flow and don't require a minimum pressure drop between the inlet and outlet for operation.

Valves are full port, so they do not restrict flow. The actuator is secured to the valve body with a bracket for easy disassembly, maintenance, and repair. A visual flow indicator on the top of the actuator shows whether the valve is open or closed. The manual override allows you to operate the valve during power outages.

Single-acting actuators only require air pressure to open the valve; they automatically spring closed when the air turns off. These valves are normally closed unless actuated. Double-acting actuators require air pressure to open and close the valve. Once actuated, these valves remain actuated until air pressure is applied to close them, so they do not have a valve starting position.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Bolts | Air | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Gender | Flange OD | No. of Holes | Hole Size | Included | Circle Dia. | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Connection | Pressure Range, psi | Each | |

316 Stainless Steel Body with Screw Terminals | |||||||||||||||||

Single Acting: Air-to-Open, Spring Return (Normally Closed)—120V AC | |||||||||||||||||

| 2 | Female | 6" | 4 | 0.551" | No | 4 3/4" | 307 | 275 psi @ 100° F | 100 psi @ 338° F | Zero Pressure Drop | 0° to 365° | 3 1/4" | 14" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000000 |

| 3 | Female | 7 1/2" | 4 | 0.551" | No | 6" | 1,013 | 275 psi @ 100° F | 100 psi @ 338° F | Zero Pressure Drop | 0° to 365° | 4 13/16" | 18 5/16" | 1/4 NPT Female | 40 to 115 | 0000000 | 00000000 |

Double Acting: Air-to-Close, Air-to-Open—120V AC | |||||||||||||||||

| 2 | Female | 6" | 4 | 0.551" | No | 4 3/4" | 307 | 275 psi @ 100° F | 100 psi @ 338° F | Zero Pressure Drop | 0° to 365° | 3 1/4" | 13" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

| 3 | Female | 7 1/2" | 4 | 0.551" | No | 6" | 1,013 | 275 psi @ 100° F | 100 psi @ 338° F | Zero Pressure Drop | 0° to 365° | 4 13/16" | 15 1/4" | 1/4 NPT Female | 40 to 115 | 0000000 | 00000000 |

Severe-Duty Air-Driven On/Off Valves for Chemicals

- Valve Type: Diaphragm

- For Use With:

Pipe Size 1/4: Oil, Air, Propane, Butane, Acetone, Ammonia, Carbon Dioxide, Chlorine, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Nitric Acid, Nitrogen, Oxygen, Sodium Hypochlorite, Sulfuric Acid, Toluene, Citric Acid, Phosphoric Acid, Sodium Hydroxide

Pipe Size 1/2: Water, Oil, Air, Natural Gas, Propane, Butane, Acetone, Ammonia, Carbon Dioxide, Chlorine, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Nitric Acid, Nitrogen, Oxygen, Salt Water, Soap Solutions, Sodium Hypochlorite, Steam, Sulfuric Acid, Toluene, Citric Acid, Phosphoric Acid, Sodium Hydroxide

Pipe Size 3/4: Water, Oil, Air, Natural Gas, Propane, Butane, Acetone, Ammonia, Carbon Dioxide, Chlorine, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Nitric Acid, Nitrogen, Oxygen, Salt Water, Soap Solutions, Sodium Hypochlorite, Steam, Sulfuric Acid, Toluene, Citric Acid, Phosphoric Acid, Sodium Hydroxide - Seal Material : PTFE Plastic

- Seat Material: PTFE Plastic

- Actuator Housing Material: Plastic

Also known as diaphragm valves, these have a PTFE body and seals that stand up to harsh acidic solutions. The diaphragm can handle dirty liquid, slurries, and abrasive media without damage. All valves operate on compressed air to automatically start and stop flow. You must control the air to the actuator using either an electric pilot valve (not included) or a manual on/off valve (not included). These valves don’t require a minimum pressure drop between the inlet and outlet for operation.

All have a single-acting actuator that only requires air pressure to open the valve; they automatically spring closed when the air turns off. The actuator is directly mounted to the valve body to minimize movement and reduce wear. Valves are normally closed unless actuated.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Air | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Connection | Pressure Range, psi | Mounting Stud Screw Size | No. of Mounting Studs | Fasteners Included | Each | |

PTFE Plastic Body | |||||||||||||||

Single Acting: Air-to-Open, Spring Return (Normally Closed) | |||||||||||||||

| 1/4 | Female | NPT | 0.7 | 60 psi @ 140° F | Zero Pressure Drop | 35° to 175° | 2 1/8" | 2 7/8" | 1/8 NPT Female | 40 to 60 | __ | 2 | No | 00000000 | 0000000 |

| 1/2 | Female | NPT | 2.8 | 60 psi @ 140° F | Zero Pressure Drop | 35° to 210° | 2 3/4" | 3 3/8" | 1/8 NPT Female | 60 to 80 | 1/4" | 2 | No | 00000000 | 000000 |

| 120V AC Pilot Valve | 00000000 | Each | 0000000 |

Flanged Motor-Driven On/Off Valves for Chemicals

- Valve Type: Ball

- For Use With: Water, Oil, Air, Natural Gas, Propane, Butane, Acetone, Argon, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Helium, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Neon, Nitric Acid, Nitrogen, Oxygen, Salt Water, Soap Solutions, Steam, Xenon, Citric Acid, Krypton

- Ball Material: 316 Stainless Steel

- Seal Material: PTFE Plastic

- Seat Material: PTFE Plastic

- Actuator Housing Material: Aluminum

- Specifications Met: ASME B16.34

For high-flow chemical-processing applications, these valves have a ball-valve design that provides at least three times the flow of standard flanged valves. They have a 316 stainless steel body and a PTFE seal that can stand up to aggressive and corrosive solutions. Valves operate on electricity to automatically start and stop flow. They don’t require a minimum pressure drop between the inlet and outlet for operation. All are fail in place; upon the loss of power, the valve will remain in its current position. Valves are full port, so they do not restrict flow.

The actuator is secured to the valve body with a bracket for easy disassembly, maintenance, and repair. A visual flow indicator on the top of the actuator shows whether the valve is open or closed. Two single pole, double throw (SPDT) auxiliary switches allow you to connect these valves to temperature-monitoring equipment, programmable logic controllers, or conveyor sirens. The internal heater automatically turns on when the valve is actuated to prevent motor damage caused by condensation buildup. The manual override allows you to operate the valve during power outages.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Bolts | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Gender | Flange OD | No. of Holes | Hole Size | Included | Circle Dia. | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Each | |

316 Stainless Steel Body with Screw Terminals | |||||||||||||||

Fail in Place—24V AC/24V DC | |||||||||||||||

| 2 | Female | 6" | 4 | 5/8" | No | 4 3/4" | 307 | 275 psi @ 100° F | 100 psi @ 338° F | Zero Pressure Drop | 0° to 365° | 3 1/4" | 19 1/16" | 0000000 | 000000000 |

| 3 | Female | 7 1/4" | 4 | 5/8" | No | 6" | 1,013 | 275 psi @ 100° F | 100 psi @ 338° F | Zero Pressure Drop | 0° to 365° | 4 13/16" | 22 5/8" | 0000000 | 00000000 |

Fail in Place—120V AC | |||||||||||||||

| 2 | Female | 6" | 4 | 5/8" | No | 4 3/4" | 307 | 275 psi @ 100° F | 100 psi @ 338° F | Zero Pressure Drop | 0° to 365° | 3 1/4" | 19 1/16" | 0000000 | 00000000 |

| 3 | Female | 7 1/4" | 4 | 5/8" | No | 6" | 1,013 | 275 psi @ 100° F | 100 psi @ 338° F | Zero Pressure Drop | 0° to 365° | 4 13/16" | 22 5/8" | 0000000 | 00000000 |

Ultra-Chemical-Resistant Threaded Check Valves

- For Use With: Acetone, Ammonia, Butane, Carbon Dioxide, Citric Acid, Diesel Fuel, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Nitric Acid, Nitrogen, Oil, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Sulfuric Acid, Toluene, Water, Xylene

- Piston Material: PTFE Plastic

- Spring Material: PTFE Plastic

The most chemical-resistant check valves in our offering, these have a PFA body to withstand methyl ethyl ketone, sodium hypochlorite, and other extremely harsh chemicals. They open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | Each | |

PFA Plastic Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||||

| 1/4 | 0.75 | 125 psi @ 150° F | 1 | 0° to 210° | Semi-Clear White | 2 3/8" | 00000000 | 0000000 |

| 1/2 | 4 | 100 psi @ 150° F | 1 | 0° to 210° | Semi-Clear White | 3 3/8" | 00000000 | 000000 |

NPT Female × NPT Male | ||||||||

| 1/4 | 0.75 | 125 psi @ 150° F | 1 | 0° to 210° | Semi-Clear White | 2 7/16" | 00000000 | 000000 |

NPT Male × NPT Female | ||||||||

| 1/4 | 0.75 | 125 psi @ 150° F | 1 | 0° to 210° | Semi-Clear White | 2 1/16" | 00000000 | 000000 |

NPT Male × NPT Male | ||||||||

| 1/4 | 0.75 | 125 psi @ 150° F | 1 | 0° to 210° | Semi-Clear White | 2 7/16" | 00000000 | 000000 |

Flanged Check Valves for Harsh Chemicals

- For Use With: Ammonia, Chlorine, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Oil, Phosphoric Acid, Salt Water, Soap Solutions, Toluene, Water, Xylene

- Ball Material: PTFE Plastic

- Seal Material: PTFE Plastic

Bolt these valves to ANSI flanges. The glass-filled vinyl ester body and PTFE seal stand up to a wide range of harsh chemicals. Valves open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | For Flange Class | Flange OD | Number of Bolt Holes | Bolt Hole Size | Bolt Circle Dia. | Bolts Included | Each | |

Glass-Filled Vinyl Ester Body | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||||||||

| 1 | 35 | 200 psi @ 250 ° F | 1 | -40° to 250° | Beige | 5" | 150 | 4 1/4" | 4 | 5/8" | 3 1/8" | No | 000000 | 0000000 |

| 2 | 54 | 140 psi @ 250 ° F | 1 | -40° to 250° | Beige | 7" | 150 | 6" | 4 | 3/4" | 4 3/4" | No | 000000 | 000000 |

Vacuum-Breaking Valves for Chemicals

A plastic body withstands pH neutralizing, cleaning, and plating solutions containing sodium hydroxide, methyl ethyl ketone, and other harsh chemicals. Also known as vacuum breakers, these valves have vents that open when pressure drops to relieve vacuum conditions and prevent backward suction from drawing liquid into upstream piping.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Ammonia, Argon, Beverage, Carbon Dioxide, Chlorinated Water, Diesel Fuel, Drinking Water, Ethylene Glycol, Food, Helium, Hydrochloric Acid, Kerosene, Krypton, Liquid Carbon Dioxide, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Water, Xenon

- Diaphragm Material: Fluoroelastomer Rubber

- Seal Material: Fluoroelastomer Rubber

| Pipe Size | For Pipe Schedule | Max. Pressure | Min. Opening Pressure, psi | End-to-End Lg. | Color | Temperature Range, °F | Each | |

PVC Plastic Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||||

| 1/2 | 80 | 100 psi @ 75° F | 1 | 4 5/16" | Gray | 40° to 140° | 000000 | 0000000 |

| 3/4 | 80 | 100 psi @ 75° F | 1 | 4 5/8" | Gray | 40° to 140° | 0000000 | 000000 |

| 1 | 80 | 100 psi @ 75° F | 1 | 5 1/8" | Gray | 40° to 140° | 0000000 | 000000 |

CPVC Plastic Body | ||||||||

NPT Female × NPT Female | ||||||||

| 1/2 | 80 | 100 psi @ 75° F | 1 | 4 5/16" | Light Gray | 40° to 180° | 0000000 | 000000 |

| 3/4 | 80 | 100 psi @ 75° F | 1 | 4 5/8" | Light Gray | 40° to 180° | 0000000 | 000000 |

| 1 | 80 | 100 psi @ 75° F | 1 | 5 1/8" | Light Gray | 40° to 180° | 0000000 | 000000 |

- For Use With: Air, Ammonia, Argon, Beverage, Carbon Dioxide, Chlorinated Water, Diesel Fuel, Drinking Water, Ethylene Glycol, Food, Helium, Hydrochloric Acid, Kerosene, Krypton, Liquid Carbon Dioxide, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Water, Xenon

- Piston Material:

PVC Plastic Body: PVC Plastic

CPVC Plastic Body: CPVC Plastic - Spring Material: Plastic Polymer

- Seal Material: Fluoroelastomer Rubber

| Pipe Size | For Pipe Schedule | Max. Pressure | Min. Opening Pressure, psi | End-to-End Lg. | Color | Temperature Range, °F | Each | |

PVC Plastic Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||||

| 2 | 80 | 100 psi @ 75° F | 1 | 8 1/2" | Gray | 40° to 140° | 0000000 | 0000000 |

CPVC Plastic Body | ||||||||

NPT Female × NPT Female | ||||||||

| 1 1/2 | 80 | 100 psi @ 75° F | 1 | 7 15/16" | Light Gray | 40° to 180° | 0000000 | 000000 |

Flow-Control Orifices for Chemicals

- For Use With: Air, Ammonia, Sodium Hydroxide, Beverage, Carbon Dioxide, Diesel Fuel, Water, Oil, Ethylene Glycol, Food, Hydrochloric Acid, Kerosene, Liquid Carbon Dioxide, Methanol, Soap Solutions, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Oxygen, Nitric Acid

- Max. Pressure: 120 psi @ 75° F

- Temperature Range: 40° to 140° F

Made of PVC, these orifices have excellent resistance to a wide range of corrosive chemicals. Also known as flow restrictors and precision orifice valves, they are used to throttle, vent, bleed, or regulate the flow of liquids and gases. They automatically adjust to changing inlet pressure to maintain consistent outlet flow.