About Gas Regulators

More

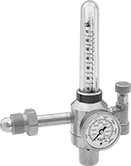

Easy-Read Tank-Mount Pressure-Regulating

Valves with Flowmeter for Inert Gas

Flowmeters let you see the gas flow rate from a distance. These valves automatically reduce a high inlet pressure from compressed gas tanks to a lower, stable outlet pressure. All have Compressed Gas Association (CGA) numbered inlet fittings for secure connections to compressed gas tanks. Choose a valve with the same CGA number as your tank and other system components. They have a gauge for monitoring inlet pressure from the tank.

Single-stage valves reduce pressure in one step, which causes the outlet pressure to fluctuate slightly as you empty the tank. They’re best for applications where a constant outlet pressure isn’t critical.

Valves with one flowmeter are for one piece of equipment on a tank. The flowmeter has a single scale.

Adapters (sold separately) change 5/8"-18 outlets to 9/16"-18 male connections, and vice versa.

Inlet | Outlet | Material | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Location | Thread Direction | Pressure Gauge Range, psi | Stage | Thread Size | Location | Thread Direction | Flow Range, scfh | Number of Flowmeters | Body | Seal | Diaphragm | Each | |

UNF Female Outlet × NGO Male Inlet | ||||||||||||||

| CGA 580 | Side | Right Hand | 0 to 4,000 | Single | 5/8"-18 | Side | Right Hand | 0 to 100 (Helium), 0 to 140 (Hydrogen) | 1 | Brass | PTFE | Neoprene | 000000000 | 0000000 |

| Optional Adapter | 00000000 | Each | 000000 |

Inlet | Outlet | Material | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Location | Thread Direction | Pressure Gauge Range, psi | Stage | Thread Size | Location | Thread Direction | Flow Range, scfh | Number of Flowmeters | Body | Seal | Diaphragm | Each | |

UNF Male Outlet × NGO Female Inlet | ||||||||||||||

| CGA 350 | Side | Left Hand | 0 to 3,000 | Single | 9/16"-18 | Side | Left Hand | 0 to 40 | 1 | Brass | PTFE | Neoprene | 000000000 | 0000000 |

| Optional Adapter | 00000000 | Each | 000000 |