Filter by

Tool Type

Cut Style

Export Control Classification Number (ECCN)

REACH

DFARS Specialty Metals

Finish

Straight and Spiral Router Bits for Foam

Uncoated High-Speed Steel

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

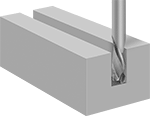

Square Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 2 1/8" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1" | 1/4" | 3 1/4" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1" | 1/2" | 2 1/2" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1" | 3/8" | 2 1/2" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/4" | 1/2" | 2 3/4" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated Carbide

|

Square Cut Style—Plunge-Cut |

Square Cut Style—Plunge-Cut, Spiral Flute |

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Square Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Upward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 1/8" | 1/4" | 2 1/2" | 2 | CNC Machine | Foam | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 5/8" | 3/16" | 4" | 2 | CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 1/4" | 4" | 2 | CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3" | 1/4" | 6" | 2 | CNC Machine | Foam | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 4" | 3/8" | 6" | 2 | CNC Machine | Foam | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Downward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 1/16" | 1/8" | 3" | 2 | CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 1/4" | 4" | 2 | CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic-Coated Carbide

|

Square Cut Style—Plunge-Cut |

Square Cut Style—Plunge-Cut, Spiral Flute |

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Square Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Upward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 1/8" | 1/4" | 2 1/2" | 2 | CNC Machine | Foam | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 1/4" | 4" | 2 | CNC Machine | Foam | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Downward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 1/8" | 1/4" | 2 1/2" | 2 | CNC Machine | Foam | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 1/4" | 4" | 2 | CNC Machine | Foam | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trimming Router Bits

Uncoated Carbide

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Router Bit Pilot Type | Ball Bearing Pilot Dia. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

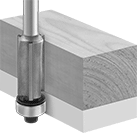

Flush-Trimming Cut Style (Bottom Pilot) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5/8" | 1/4" | 2 3/8" | Ball Bearing | 1/4" | 2 | Hand Router, Router Table | Wood, Particleboard, Plywood, Hard Plastic, Soft Plastic, Aluminum, Laminate, Foam, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 3" | Ball Bearing | 1/4" | 2 | Hand Router, Router Table | Wood, Particleboard, Plywood, Hard Plastic, Soft Plastic, Laminate, Foam, Composite | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/8" | 1/2" | 4" | Ball Bearing | 1/2" | 2 | Hand Router, Router Table | Wood, Particleboard, Plywood, Hard Plastic, Soft Plastic, Laminate, Foam, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Engraving Router Bits

Uncoated Diamond-Tipped Stainless Steel

Router Bits | Replacement 120° Cut Angle Tips | 90° Cut Angle Tips | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cutting Dia. | Lg. of Cut | Cut Angle | Shank Dia. | Overall Lg. | For Tool Type | For Use On | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

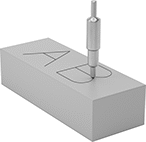

Engraving Cut Style | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fluteless | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | 1/32" | 120° | 1/4" | 3 3/4" | CNC Machine | Wood, Hard Plastic, Aluminum, Copper, Steel, Granite, Glass, Plastic, Foam | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | 1/32" | 120° | 1/2" | 3 3/4" | CNC Machine | Wood, Hard Plastic, Aluminum, Copper, Steel, Granite, Glass, Plastic, Foam | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||