Wear-Resistant Easy-to-Machine Delrin® Acetal Resin Balls

- Color: White

- Temperature Range: -20° to 180° F

- Tensile Strength: 10,000-11,000 psi (Good)

- Impact Strength: 1-1.5 ft.-lbs./in. (Poor)

- Hardness: Rockwell R120-R122 (Hard)

- For Use Outdoors: No

- Specifications Met: FDA Compliant 21 CFR 177.2480

Able to hold tight tolerances, these balls resist expanding when exposed to heat and moisture. They have a naturally slippery, wear-resistant surface. Use them for bearings and low-load rolling applications. Delrin® acetal resin is also known as acetal homopolymer.

| Dia. | Dia. Tolerance | Pkg. Qty. | Pkg. | |

Inch | ||||

|---|---|---|---|---|

| 1/16" | -0.001" to 0.001" | 100 | 000000 | 00000 |

| 3/32" | -0.001" to 0.001" | 100 | 0000000 | 0000 |

| 1/8" | -0.001" to 0.001" | 100 | 0000000 | 0000 |

| 9/64" | -0.001" to 0.001" | 100 | 0000000 | 0000 |

| 5/32" | -0.001" to 0.001" | 100 | 0000000 | 0000 |

| 3/16" | -0.001" to 0.001" | 100 | 0000000 | 0000 |

| 7/32" | -0.001" to 0.001" | 100 | 0000000 | 0000 |

| 1/4" | -0.001" to 0.001" | 100 | 0000000 | 0000 |

| 9/32" | -0.001" to 0.001" | 25 | 0000000 | 0000 |

| 5/16" | -0.001" to 0.001" | 100 | 0000000 | 0000 |

| 3/8" | -0.001" to 0.001" | 100 | 0000000 | 00000 |

| 7/16" | -0.001" to 0.001" | 50 | 0000000 | 00000 |

| 1/2" | -0.001" to 0.001" | 50 | 0000000 | 00000 |

| 9/16" | -0.001" to 0.001" | 25 | 0000000 | 0000 |

| 5/8" | -0.001" to 0.001" | 25 | 000000 | 00000 |

| 3/4" | -0.001" to 0.001" | 10 | 0000000 | 0000 |

| 13/16" | -0.001" to 0.001" | 1 | 0000000 | 0000 |

| 7/8" | -0.001" to 0.001" | 10 | 0000000 | 00000 |

| 15/16" | -0.001" to 0.001" | 1 | 0000000 | 0000 |

| 1" | -0.001" to 0.001" | 10 | 0000000 | 00000 |

| 1 1/8" | -0.002" to 0.002" | 1 | 0000000 | 0000 |

| 1 1/4" | -0.002" to 0.002" | 1 | 0000000 | 0000 |

| 1 1/2" | -0.002" to 0.002" | 1 | 0000000 | 0000 |

| 2" | -0.002" to 0.002" | 1 | 0000000 | 00000 |

Metric | ||||

| 2mm | -0.0254mm to 0.0254mm | 100 | 0000000 | 0000 |

| 3.5mm | -0.0254mm to 0.0254mm | 100 | 0000000 | 0000 |

| 4mm | -0.0254mm to 0.0254mm | 100 | 0000000 | 0000 |

| 5mm | -0.0254mm to 0.0254mm | 100 | 0000000 | 0000 |

| 8mm | -0.0254mm to 0.0254mm | 50 | 0000000 | 0000 |

Polypropylene Balls

- Color: Semi-Clear White

- Max. Temperature:

Solid Balls: 180° F

Hollow Balls: 220° F - Tensile Strength: 2,900-5,070 psi (Poor)

- Impact Strength: 0.9 ft.-lbs./in. (Poor)

- Hardness: Rockwell R99 (Hard)

- For Use Outdoors: No

- Specifications Met: See table

Resistant to swelling when exposed to water, these balls are often used in laboratory applications.

Hollow balls float. Use them in tanks to slow evaporation and reduce heat loss.

| Dia. | Dia. Tolerance | Specifications Met | Pkg. Qty. | Pkg. | |

Hollow | |||||

|---|---|---|---|---|---|

| 0.787" | -0.010" to 0.010" | FDA Compliant 21 CFR 177.1520 | 150 | 0000000 | 000000 |

| 1" | -0.015" to 0.015" | FDA Compliant 21 CFR 177.1520 | 25 | 0000000 | 0000 |

| 1.4" | -0.015" to 0.015" | FDA Compliant 21 CFR 177.1520 | 25 | 0000000 | 0000 |

| 1.496" | -0.010" to 0.010" | FDA Compliant 21 CFR 177.1520 | 50 | 0000000 | 00000 |

| 1.969" | -0.020" to 0.020" | FDA Compliant 21 CFR 177.1520 | 40 | 0000000 | 00000 |

| 3.15" | -0.030" to 0.030" | FDA Compliant 21 CFR 177.1520 | 10 | 0000000 | 00000 |

| 3.937" | -0.050" to 0.050" | FDA Compliant 21 CFR 177.1520 | 1 | 0000000 | 0000 |

Food Industry Abrasion-Resistant Polyurethane Rubber Balls

- Color: Gray

- Temperature Range: -94° to 305° F

- Tensile Strength: 800 psi

- For Use Outdoors: No

Safely use these balls in food and pharmaceutical environments to clean screens in vibrating sifters or to act as a seal in pumps and check valves. They're polyurethane with metal and chemical additives, which means they absorb shock and resist abrasion like rubber and are strong like plastic but also include additives that make them detectable on hygienic lines. These additives will set off metal detectors, X-ray machines, and magnetic traps if these balls fall into food. This helps you comply with Hazard Analysis and Critical Control Point (HACCP) programs. These balls do not contain BPA or plasticizers, so they won’t cause contamination or impart tastes or odors to products. They are FDA compliant for direct contact with food.

| Dia. | Dia. Tolerance | Durometer | Performance Properties | Specifications Met | Each | |

| 1 3/8" | -0.016" to +0.016" | 65A (Medium Hard) | Metal Detectable, X-Ray Detectable | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 |

Food Industry Abrasion-Resistant Natural Rubber Balls

- Color: White

- Temperature Range: 0° to 180° F

- Tensile Strength: 3,000 psi

- For Use Outdoors: No

FDA compliant for direct contact with food, these balls are often used to clean screens in vibrating sifters in food, beverage, and other sanitary environments. You can also use them as seals in pumps and check valves. All are made of natural rubber, which is also known as gum rubber and latex rubber.

| Dia. | Dia. Tolerance | Durometer | Specifications Met | Pkg. Qty. | Pkg. | |

| 5/8" | -0.115" to +0.125" | 45A (Medium Soft) | FDA Compliant 21 CFR 177.2600 | 10 | 00000000 | 000000 |

| 1" | -0.115" to +0.125" | 45A (Medium Soft) | FDA Compliant 21 CFR 177.2600 | 10 | 00000000 | 00000 |

| 1 1/8" | -0.115" to +0.125" | 45A (Medium Soft) | FDA Compliant 21 CFR 177.2600 | 5 | 00000000 | 00000 |

| 1 3/8" | -0.115" to +0.125" | 45A (Medium Soft) | FDA Compliant 21 CFR 177.2600 | 5 | 00000000 | 00000 |

| 2" | -0.115" to +0.125" | 45A (Medium Soft) | FDA Compliant 21 CFR 177.2600 | 1 | 00000000 | 0000 |

Food Industry Multipurpose Neoprene Rubber Balls

- Color: White

- Temperature Range: 0° to 212° F

- Tensile Strength: 2,000 psi

- For Use Outdoors: Yes

Loosen fine particles from the grip of vibrating-sifter screens with the bounce of rubber balls. Also use them as seals in pumps and check valves. They’re made from FDA-listed materials for use with food and beverage. Neoprene is also known as chloroprene.

| Dia. | Dia. Tolerance | Durometer | Specifications Met | Pkg. Qty. | Pkg. | |

| 5/8" | -0.115" to +0.125" | 55A (Medium) | FDA Compliant 21 CFR 177.2600 | 10 | 00000000 | 000000 |

| 1" | -0.115" to +0.125" | 55A (Medium) | FDA Compliant 21 CFR 177.2600 | 10 | 00000000 | 00000 |

| 1 1/8" | -0.115" to +0.125" | 55A (Medium) | FDA Compliant 21 CFR 177.2600 | 5 | 00000000 | 00000 |

| 1 3/8" | -0.115" to +0.125" | 55A (Medium) | FDA Compliant 21 CFR 177.2600 | 5 | 00000000 | 00000 |

| 2" | -0.115" to +0.125" | 55A (Medium) | FDA Compliant 21 CFR 177.2600 | 2 | 00000000 | 00000 |

High-Temperature Silicone Rubber Balls

- Color: White (semi-clear)

- Temperature Range: 0° to 400° F

- Tensile Strength: 2,000 psi

- For Use Outdoors: No

Use these balls as seals in pumps and check valves, or let them bounce inside of vibrating sifters as an effective screen cleaner. Silicone, commonly called polysiloxane, offers good resistance to ozone and salt water.

| Dia. | Dia. Tolerance | Durometer | Specifications Met | Pkg. Qty. | Pkg. | |

| 5/8" | -0.115" to +0.125" | 35A (Soft) | FDA Compliant 21 CFR 177.2600 | 10 | 0000000 | 000000 |

| 7/8" | -0.115" to +0.125" | 35A (Soft) | FDA Compliant 21 CFR 177.2600 | 5 | 0000000 | 00000 |

| 1" | -0.115" to +0.125" | 35A (Soft) | FDA Compliant 21 CFR 177.2600 | 5 | 0000000 | 00000 |

| 1 1/8" | -0.115" to +0.125" | 35A (Soft) | FDA Compliant 21 CFR 177.2600 | 1 | 0000000 | 0000 |

| 1 3/8" | -0.115" to +0.125" | 35A (Soft) | FDA Compliant 21 CFR 177.2600 | 2 | 0000000 | 00000 |

| 2" | -0.115" to +0.125" | 35A (Soft) | FDA Compliant 21 CFR 177.2600 | 1 | 0000000 | 00000 |

Foaming Agents for Plastic Molding Machines

Commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and sinks in finished parts. Mix them into resin as 0.5-1.5% of the total mixture—by decreasing the amount of resin needed to make a part, they help reduce costs. They also lower the melt viscosity of resin so that it can be processed at low temperatures, which reduces cooling times, cycle times, and the risk of heat degradation. These foaming agents are compatible with most plastic and rubber resins. All are FDA compliant for direct contact with food.

Agents with a 310° F or 325° F activation temperature are for use with low-melt-temperature resins such as polyolefins, polystyrenes, and thermoplastic elastomers. Agents with a 400° F activation temperature are for use with high-melt-temperature resins such as polycarbonates and polyamides.

Microfine agents produce smaller bubbles and a tighter cell structure than other foaming agents. They improve the appearance of your final product and keep its mechanical properties consistent throughout. They’re often used to create parts that have thin walls.

Fine agents produce more gas than microfine agents. Use them to ensure uniform foaming when molding bigger parts.

| Activation Temperature, °F | Melting Temperature, °F | Gas Evolution | Color | Container Type | Specifications Met | Each | |

Microfine | |||||||

|---|---|---|---|---|---|---|---|

| 325° | 250° | 30 cc/g and higher | White | Cardboard Box | FDA Compliant 21 CFR 174.5 | 0000000 | 0000000 |

| 325° | 250° | 65 cc/g and higher | White | Cardboard Box | FDA Compliant 21 CFR 174.5 | 0000000 | 000000 |

| 400° | 350° | 30 cc/g and higher | Off-White | Cardboard Box | FDA Compliant 21 CFR 174.5 | 0000000 | 000000 |

Fine | |||||||

| 310° | 310° | 95 cc/g and higher | White | Cardboard Box | FDA Compliant 21 CFR 174.5 | 0000000 | 000000 |

Moisture-Resistant Plastic Pellets

These pellets resist swelling when exposed to water, making them suitable for use in wet environments. Melt and mold them into desired shapes. Pellets are made from virgin resins and are compatible with various types of molding equipment such as injection molders and 3D printers.

Choose HDPE pellets for general-purpose applications such as protoyping.

HoPP and CoPP pellets are harder than HDPE pellets, so they won't scratch as easily. HoPP has greater tensile strength than CoPP. However, CoPP has better impact resistance. It resists impact even at low temperatures.

Container | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Net Weight, lbs. | Molding Temperature, °F | Melting Temperature, °F | Melt Flow Rate | Shrinkage | Hardness | Impact Strength | Tensile Strength | Clarity | Specifications Met | Each | |

HDPE Plastic | ||||||||||||

White | ||||||||||||

| Pail | 5 | 80° to 140° | 375° to 440° | 6 g/10 min | 1.2%-2% | Shore D62 (Medium) | 1 ft.-lbs./in. (Poor) | 4,100 psi (Poor) | Opaque | FDA Compliant 21 CFR 177.1520 | 0000000 | 0000000 |

| Cardboard Box | 50 | 80° to 140° | 375° to 440° | 6 g/10 min | 1.2%-2% | Shore D62 (Medium) | 1 ft.-lbs./in. (Poor) | 4,100 psi (Poor) | Opaque | FDA Compliant 21 CFR 177.1520 | 0000000 | 000000 |

HoPP Plastic | ||||||||||||

White | ||||||||||||

| Pail | 5 | 90° to 150° | 375° to 450° | 12 g/10 min | 1.3%-1.7% | Rockwell R112 (Hard) | 1 ft.-lbs./in. (Poor) | 5,600 psi (Good) | Semi-Clear | FDA Compliant 21 CFR 177.1520 | 0000000 | 00000 |

CoPP Plastic | ||||||||||||

White | ||||||||||||

| Pail | 5 | 90° to 150° | 375° to 450° | 4 g/10 min | 1.3%-1.7% | Rockwell R105 (Hard) | No Break (Excellent) | 3,200 psi (Poor) | Opaque | FDA Compliant 21 CFR 177.1520 | 0000000 | 00000 |

Impact-Resistant Plastic Pellets

Absorbing impact without cracking or breaking, these plastic pellets are molded into parts that endure bumps, scrapes, and falls. Use them with injection molders, 3D printers, and other molding equipment.

HIPS pellets are easy to thermoform, so they’re good for signs, packaging, and other light duty applications.

ABS pellets are easy to thermoform, have good impact resistance at low temperatures, and have more chemical resistance than those made of HIPS or polycarbonate. They’re also more impact resistant than HIPS pellets. Use them to make storage cases, tote trays, equipment housings, and protective gear.

PVDF pellets are flexible, weather resistant, and have the most chemical resistance of all these materials. PVDF is also known as Kynar.

Polycarbonate pellets handle higher temperatures than any of these other materials, but they’re more difficult to thermoform. Clear in color and a lightweight alternative to glass, they’re often used to make windows, machine guards, and instrument covers.

Container | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Net Weight, lbs. | Molding Temperature, °F | Melting Temperature, °F | Melt Flow Rate | Shrinkage | Hardness | Impact Strength | Tensile Strength | Clarity | Specifications Met | Each | |

HIPS Plastic | ||||||||||||

Off-White | ||||||||||||

| Pail | 5 | 100° to 150° | 410° to 480° | 9 g/10 min | 0.3%-0.6% | Rockwell R105 (Hard) | 2 ft.-lbs./in. (Good) | 3,550 psi (Poor) | Opaque | FDA Compliant 21 CFR 177.1020 | 0000000 | 000000 |

| Cardboard Box | 55 | 100° to 150° | 410° to 480° | 9 g/10 min | 0.3%-0.6% | Rockwell R105 (Hard) | 2 ft.-lbs./in. (Good) | 3,550 psi (Poor) | Opaque | FDA Compliant 21 CFR 177.1020 | 0000000 | 000000 |

ABS Plastic | ||||||||||||

Off-White | ||||||||||||

| Pail | 5 | 145° to 185° | 400° to 460° | 35 g/10 min | 0.5%-0.8% | Rockwell R108 (Hard) | 5.5 ft.-lbs./in. (Excellent) | 6,500 psi (Good) | Opaque | FDA Compliant 21 CFR 177.1020 | 0000000 | 000000 |

| Cardboard Box | 55 | 145° to 185° | 400° to 460° | 35 g/10 min | 0.5%-0.8% | Rockwell R108 (Hard) | 5.5 ft.-lbs./in. (Excellent) | 6,500 psi (Good) | Opaque | FDA Compliant 21 CFR 177.1020 | 0000000 | 000000 |

PVDF Plastic | ||||||||||||

Off-White | ||||||||||||

| Jar | 5 | 125° to 190° | 270° to 280° | 8 g/10 min | 2%-3.5% | Durometer 57D (Medium Soft) | No Break (Excellent) | 2,000 psi (Poor) | Semi-Clear | FDA Compliant 21 CFR 177.1520 | 0000000 | 000000 |

Polycarbonate Plastic | ||||||||||||

Clear | ||||||||||||

| Pail | 6 | 180° to 240° | 540° to 590° | 22 g/10 min | 0.5%-0.7% | Rockwell R120 (Hard) | 14 ft.-lbs./in. (Excellent) | 9,100 psi (Good) | Transparent | FDA Compliant 21 CFR 177.1580 | 0000000 | 000000 |

| Cardboard Box | 50 | 180° to 240° | 540° to 590° | 22 g/10 min | 0.5%-0.7% | Rockwell R120 (Hard) | 14 ft.-lbs./in. (Excellent) | 9,100 psi (Good) | Transparent | FDA Compliant 21 CFR 177.1580 | 0000000 | 000000 |

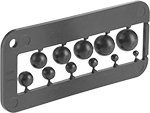

Calibration Kit for Metal-Detectable Plastics

Made with metal additives, these balls test the sensitivity of food-processing metal detectors. They’re often used to calibrate metal detectors to find metal-detectable plastic tools that have fallen into a batch. To calibrate your metal detector, run different balls through the line—the smaller the ball, the more sensitive the detector must be to recognize it. Since they’re spheres, their orientation won’t affect a metal detector’s ability to register them. These balls help you comply with Hazard and Critical Control Point (HACCP) programs for food safety. They’re FDA compliant for direct contact with food. Balls are autoclavable, so you can sanitize them with steam.

| Material | Color | Max. Temperature, °F | Autoclavable | Includes | Specifications Met | Each | |

| Polypropylene Plastic | Blue | 180° | Yes | Sizes 4 mm to 14 mm (1 mm increments) | FDA Compliant 21 CFR 177.1520 | 0000000 | 00000 |