Filter by

Environment

Food Industry Standard

Material

System of Measurement

Stud Material

Color

Insert Material

Handle Style

RoHS

Export Control Classification Number (ECCN)

Certification

Sanitary Threaded-Hole Knobs

Ribbed Grip

Knobs | Replacement Seals | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | Head, mm | Hub, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sz. | Dp., mm | Dia. | Ht. | Dia. | Ht. | Temp. Range, ° F | Food Industry Std. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel—Polished | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 12 | 40 | 16 | 18 | 15 | -10 to 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 15 | 40 | 16 | 18 | 15 | -10 to 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 15 | 50 | 17 | 21 | 17 | -10 to 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 18 | 50 | 17 | 21 | 17 | -10 to 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three-Arm Grip

Knobs | Replacement Seals | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | Head, mm | Hub, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sz. | Dp., mm | Dia. | Ht. | Dia. | Ht. | Temp. Range, ° F | Food Industry Std. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel—Polished | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 12 | 40 | 11 | 18 | 15 | -10 to 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 15 | 40 | 11 | 18 | 15 | -10 to 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 15 | 50 | 13 | 21 | 17 | -10 to 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 18 | 50 | 13 | 21 | 17 | -10 to 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metal-Detectable Threaded-Hole Knobs

Knurled-Head Grip

Thread | Head, mm | Hub, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Sz. | Dp., mm | Dia. | Ht. | Dia. | Ht. | Insert Material | Temp. Range, ° F | Food Industry Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 10 | 21 | 7.5 | 12.5 | 10.5 | 303 Stainless Steel | -30 to 130 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 15 | 31 | 10 | 18.5 | 17 | 303 Stainless Steel | -30 to 130 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three-Arm Grip

Thread | Head, mm | Hub, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Sz. | Dp., mm | Dia. | Ht. | Dia. | Ht. | Insert Material | Temp. Range, ° F | Food Industry Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 | 40 | 13.5 | 16 | 13.5 | 304 Stainless Steel | -30 to 130 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 17 | 50 | 15 | 19 | 15 | 304 Stainless Steel | -30 to 130 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metal-Detectable Threaded-Stud Knobs

Three-Arm Grip

Head, mm | Hub, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg., mm | Dia. | Ht. | Dia. | Ht. | Stud Material | Temp. Range, ° F | Food Industry Std. | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 20 | 40 | 13.5 | 16 | 13.5 | 304 Stainless Steel | -30 to 130 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | ISO 4753 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 30 | 40 | 13.5 | 16 | 13.5 | 304 Stainless Steel | -30 to 130 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | ISO 4753 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 30 | 50 | 15 | 19 | 15 | 304 Stainless Steel | -30 to 130 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | ISO 4753 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 40 | 50 | 15 | 19 | 15 | 304 Stainless Steel | -30 to 130 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | ISO 4753 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Threaded-Stud-Mount Pull Knobs

Knobs | Replacement Seals | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Head, mm | Hub, mm | Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Stud Lg., mm | Dia. | Ht. | Dia. | Ht. | Pull Cap. | Min. | Max. | Food Industry Std. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Smooth Grip with Buna-N Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel—Polished | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 10 | 20 | 5 | 14 | 19 | Not Rated | -10 | 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 12 | 25 | 7 | 16 | 22 | Not Rated | -10 | 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 14 | 32 | 8 | 18 | 29 | Not Rated | -10 | 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Thumb Screws

Thumb Screws | EPDM Sealing Washers | Fluoroprene Fluoroelastomer Sealing Washers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Head, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lg., mm | Wd. | Ht. | Threading | Tensile Strength | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 × 0.7 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 20 | 19 | Fully Threaded | Not Rated | 00000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M5 × 0.8 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 21 | 21 | Fully Threaded | Not Rated | 00000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 25 | 25 | Fully Threaded | Not Rated | 00000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M8 × 1.25 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 33 | 33 | Fully Threaded | Not Rated | 00000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M10 × 1.5 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 40 | 40 | Fully Threaded | Not Rated | 00000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Threaded-Hole-Mount Pull Knobs

Knobs | Replacement Seals | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | Head, mm | Hub, mm | Temp., ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Size | Dp., mm | Dia. | Ht. | Dia. | Ht. | Pull Cap. | Mounting Fasteners Included | Min. | Max. | Food Industry Std. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Smooth Grip with Buna-N Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel—Polished | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 7 | 20 | 5 | 14 | 19 | Not Rated | No | -10 | 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 9 | 25 | 7 | 16 | 22 | Not Rated | No | -10 | 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 12 | 32 | 8 | 18 | 29 | Not Rated | No | -10 | 300 | FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Food and Beverage Adjustable Handles

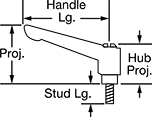

Threaded Stud

Metal-Detectable Tapered Lever Handles

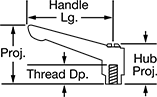

Threaded Hole

| --263ad7128161610655044-p9@halfx_637462302512265131.png?ver=ImageNotFound) |

Thread | Dia., mm | Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp., mm | Handle Lg., mm | (A) | (B) | Min. | Max. | Food Industry Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 55 | 80 | 26 | 21 | -20 | 110 | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

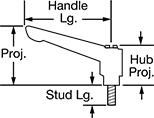

Metal-Detectable Adjustable Handles

Threaded Stud

Thread Size | Stud Lg., mm | Handle Lg., mm | Projection, mm | Hub Projection, mm | Stud Material | Temp. Range, ° F | Color | Food Industry Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 16 | 63 | 38.5 | 31 | 303 Stainless Steel | -30 to 130 | Blue | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 25 | 63 | 38.5 | 31 | 303 Stainless Steel | -30 to 130 | Blue | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 x 1.25 mm | 20 | 78 | 45 | 36 | 303 Stainless Steel | -30 to 130 | Blue | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 x 1.25 mm | 40 | 78 | 45 | 36 | 303 Stainless Steel | -30 to 130 | Blue | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

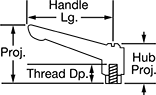

Threaded Hole

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp., mm | Handle Lg., mm | Projection, mm | Hub Projection, mm | Insert Material | Temp. Range, ° F | Color | Food Industry Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 10 | 63 | 38.5 | 31 | 303 Stainless Steel | -30 to 130 | Blue | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 x 1.25 mm | 14 | 78 | 45 | 36 | 303 Stainless Steel | -30 to 130 | Blue | FDA Compliant 21 CFR 177.1500, FDA Compliant 21 CFR 178.3297 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

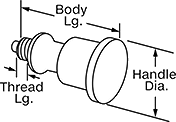

Sanitary Retractable Spring Plungers

Spring Plungers | Replacement Seals | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose, mm | Nose Force, lbf | Body | Handle | Twist-to-Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Thread Lg., mm | Extended Lg. | Dia. | Extended | Compressed | Material | Lg., mm | Material | Dia., mm | Seal Material | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 x 1.5 mm | 12 | 6 | 6 | 4.5 | 8.1 | 316 Stainless Steel | 62 | 316 Stainless Steel | 35 | Buna-N | 000000000 | 0000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 x 1.5 mm | 12 | 6 | 6 | 4.5 | 8.1 | 316 Stainless Steel | 72 | 316 Stainless Steel | 35 | Buna-N | 000000000 | 000000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 x 1.5 mm | 12 | 8 | 8 | 5 | 7.2 | 316 Stainless Steel | 77 | 316 Stainless Steel | 35 | Buna-N | 000000000 | 000000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 x 1.5 mm | 12 | 8 | 8 | 5 | 7.2 | 316 Stainless Steel | 66 | 316 Stainless Steel | 35 | Buna-N | 000000000 | 000000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metal-Detectable Threaded Through-Hole-Mount Pull Handles

Mounting Hole | Grip, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of | Ctr.-to-Ctr. Wd., mm | Wd., mm | Thread Size | Ht. | Thk. | Projection, mm | Pull Cap., lbf | Mounting Fasteners Included | Food Industry Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangular Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Nylon with Stainless Steel Insert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 117 | 134 | M8 × 1.25 mm | 25 | 15 | 49 | 1,010 | No | FDA Compliant 21 CFR 177.1500 FDA Compliant 21 CFR 178.3297 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 179 | 196 | M8 × 1.25 mm | 27 | 16 | 57 | 670 | No | FDA Compliant 21 CFR 177.1500 FDA Compliant 21 CFR 178.3297 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Food and Beverage Threaded Through-Hole-Mount Pull Handles

Handles | Replacement Seals | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No. of | Ctr.-to-Ctr. Wd., mm | Wd., mm | Thread Size | Grip Dia., mm | Projection, mm | Pull Cap. | Mounting Fasteners Included | Certification | Food Industry Std. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Grip with Buna-N Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 125 | 138 | M5 × 0.8 mm | 12 | 51 | Not Rated | No | — | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 | 173 | M5 × 0.8 mm | 12 | 51 | Not Rated | No | — | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 | 177 | M6 × 1 mm | 16 | 59 | Not Rated | No | — | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 200 | 217 | M6 × 1 mm | 16 | 59 | Not Rated | No | — | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel—Polished | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 125 | 138 | M5 × 0.8 mm | 12 | 51 | Not Rated | No | DGUV Certified GS-NV 6 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 | 173 | M5 × 0.8 mm | 12 | 51 | Not Rated | No | DGUV Certified GS-NV 6 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 | 177 | M6 × 1 mm | 16 | 59 | Not Rated | No | DGUV Certified GS-NV 6 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 200 | 217 | M6 × 1 mm | 16 | 59 | Not Rated | No | DGUV Certified GS-NV 6 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Grip with EPDM Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 125 | 138 | M5 × 0.8 mm | 12 | 51 | Not Rated | No | — | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 | 173 | M5 × 0.8 mm | 12 | 51 | Not Rated | No | — | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 | 177 | M6 × 1 mm | 16 | 59 | Not Rated | No | — | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 200 | 217 | M6 × 1 mm | 16 | 59 | Not Rated | No | — | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel—Polished | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 125 | 138 | M5 × 0.8 mm | 12 | 51 | Not Rated | No | DGUV Certified GS-NV 6 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 | 173 | M5 × 0.8 mm | 12 | 51 | Not Rated | No | DGUV Certified GS-NV 6 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 | 177 | M6 × 1 mm | 16 | 59 | Not Rated | No | DGUV Certified GS-NV 6 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 200 | 217 | M6 × 1 mm | 16 | 59 | Not Rated | No | DGUV Certified GS-NV 6 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||