Filter by

Capacity

Fuel Type

Height

Specifications Met

DFARS Specialty Metals

Dispenser Type

Finish

Export Control Classification Number (ECCN)

Certification

Faucet Material

Elevated Steel Tanks

Top Openings | Drain | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Wd. | Dp. | Ht. | Ga. | Color | Pipe Size (No. of) | Gender | Pipe Size | Gender | Channel Thk. | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 185 | 40" | 38" | 41" | 10 | Red | 2 NPT (4), 3 NPT (1) | Female | 1 NPT | Female | 1/4" | UL 142 | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 | 60" | 38" | 41" | 10 | Red | 2 NPT (4), 3 NPT (1) | Female | 1 NPT | Female | 1/4" | UL 142 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 | 65" | 48" | 51" | 10 | Red | 2 NPT (4), 4 NPT (1) | Female | 1 NPT | Female | 1/4" | UL 142 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Fuel Tanks

Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Wd. | Dp. | Ht. | Thk. | Fill Opening Dia. | Color | Clarity | Connection | Pipe Size | Gender | Seal Material | Max. Temp., ° F | Specs. Met | UV Protection | Features | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 24" | 18" | 11 5/8" | 3/16" | 1 3/4" | Red | Opaque | Threaded | 1/4 NPT | Female | Buna-N | 140 | CARB Compliant 13 CCR 2850-2869 | UV Resistant | Fuel Level Gauge | Fill Cap | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Double-Wall Plastic Tanks

Primary Compartment Openings | Secondary Compartment Openings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Wd. | Dp. | Ht. | Color | Clarity | Max. Temp., ° F | Pipe Size (No. of) | Fill Dia. (No. of) | Dia. (No. of) | Gender | Pipe Size (No. of) | Gender | Specs. Met | UV Protection | Food Industry Std. | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 14" | 14" | 22" | Blue | Opaque | 130 | 2 NPT (1) | 4" (1) | 3/8" (1) | Female | 1 NPT (1) | Female | EPA Compliant 40 CFR 264.175 | UV Resistant | NSF/ANSI 61 | Vented Fill Cap | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 18" | 18" | 24" | Blue | Opaque | 130 | 2 NPT (2) | 8" (1) | 3/8" (1) | Female | 1 NPT (1) | Female | EPA Compliant 40 CFR 264.175 | UV Resistant | NSF/ANSI 61 | Vented Fill Cap | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 20" | 20" | 38" | Blue | Opaque | 130 | 2 NPT (2) | 8" (1) | 3/8" (1) | Female | 1 NPT (1) | Female | EPA Compliant 40 CFR 264.175 | UV Resistant | NSF/ANSI 61 | Vented Fill Cap | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 24" | 24" | 41" | Blue | Opaque | 130 | 2 NPT (2) | 8" (1) | 3/8" (1) | Female | 1 NPT (1) | Female | EPA Compliant 40 CFR 264.175 | UV Resistant | NSF/ANSI 61 | Vented Fill Cap | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

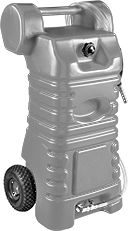

Mobile Fuel Dispensers

|  |  |

Style A | Style B | Style C |

Wheel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Fuel Type | Cap., gal. | Flow Rate, gpm | Lg. | Wd. | Ht. | Fill Opening Dia. | Nozzle OD | Hose Lg., ft. | Color | Finished Material | Material | Type | Includes | Certification | Shipping Std. | UN Shipping Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gravity Flow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Gasoline | 14 | 2 | 11" | 17" | 34" | 1 3/4" | 1" | 10 | Red | Plastic | Plastic | Solid | — | — | UN3H1/Y/130 | — | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Diesel Fuel | 25 | 2 | 17" | 22" | 43" | 2" | 3/4" | 8 | Yellow | Plastic | Rubber | Pneumatic | — | — | UN3H1W/Y1.2/110 | UN3H1W | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Gasoline | 25 | 2 | 17" | 22" | 43" | 2" | 3/4" | 8 | Red | Plastic | Rubber | Pneumatic | — | — | UN3H1W/Y1.2/110 | UN3H1W | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hand Pump | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | Diesel Fuel | 34 | 4 | 48" | 17" | 39" | 1 1/2" | 3/4" | 7 | Green | Powder-Coated Steel | Rubber | Solid | 8-ft. Grounding Strap with Clamp | FM Approved | — | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | Gasoline | 34 | 4 | 48" | 17" | 39" | 1 1/2" | 3/4" | 7 | Red | Powder-Coated Steel | Rubber | Solid | 8-ft. Grounding Strap with Clamp | FM Approved | — | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Tanks with Forklift Entry

|  |

250 gal. Capacity | 500 gal. Capacity |

Max. Fork | Top Openings | Drain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Dia. | Ht. | Ga. | No. of Entry Points for Forklifts | Wd. | Ht. | Color | Pipe Size (No. of) | Gender | Pipe Size | Gender | Specs. Met | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 250 | 36" | 63" | 12 | 2 | 5 3/4" | 2 5/8" | Red | 2 NPT (4), 3 NPT (1) | Female | 1 1/2 NPT | Female | UL 142 | — | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 | 46" | 75" | 10 | 2 | 5 3/4" | 2 5/8" | Red | 2 NPT (4), 4 NPT (1) | Female | 1 1/2 NPT | Female | UL 142 | Hand Grips, Steps | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fuel Cans

|  |  |

Style A | Style B | Replacement Spouts |

Fuel Cans | Replacement Spouts | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Spout | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Cap., gal. | Lg. | Wd. | Ht. | Fill Opening Dia. | Lg. | OD | Flexibility | Specs. Met | Color | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Gasoline | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 | 8 1/8" | 5 7/8" | 8" | 1 5/8" | 5" | 1 3/8" | Rigid | CARB Compliant EO G-18-082, EPA Compliant 40 CFR 59 | Red | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2 | 9 7/8" | 7 1/8" | 10" | 1 5/8" | 5" | 1 3/8" | Rigid | CARB Compliant EO G-18-082, EPA Compliant 40 CFR 59 | Red | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5 | 14 3/4" | 10 1/8" | 15 3/8" | 1 5/8" | 5" | 1 3/8" | Rigid | CARB Compliant EO G-18-082, EPA Compliant 40 CFR 59 | Red | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5 | 13 1/2" | 6 1/2" | 18 1/2" | 1 1/2" | 12" | 1" | Rigid | CARB Compliant EO G-14-079, EPA Compliant 40 CFR 59.698 | Red | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Diesel Fuel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5 | 14 3/4" | 10 1/8" | 15 3/8" | 1 5/8" | 5" | 1 3/8" | Rigid | CARB Compliant EO G-18-082, EPA Compliant 40 CFR 59 | Yellow | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Kerosene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5 | 14 3/4" | 10 1/8" | 15 3/8" | 1 5/8" | 5" | 1 3/8" | Rigid | CARB Compliant EO G-18-082, EPA Compliant 40 CFR 59 | Blue | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Safety Cans

|  |  |  |  |

Style A | Style B | Style C | Style F | Style G |

Powder-Coated Steel

|  |  |  |  |

Style A | Style B | Style C | Rigid Plastic Pour Spout | Flexible Steel Pour Spout |

Cans | Rigid Plastic Pour Spouts | Flexible Steel Pour Spouts | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Cap. | Dia. | Ht. | Fill Opening Dia. | Certification | Flammability Rating | Choose a Color | Each | Each | Each | ||||

| A | 16 fl. oz. | 4 1/2" | 6 3/4" | 7/8" | UL Listed, C-UL Listed, FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red | 0000000 | 0000000 | ——— | 0 | ——— | 0 | |

| A | 32 fl. oz. | 4 1/2" | 8 1/4" | 7/8" | UL Listed, C-UL Listed, FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red | 0000000 | 000000 | ——— | 0 | ——— | 0 | |

| B | 64 fl. oz. | 9" | 5 1/4" | 1 5/8" | UL Listed, C-UL Listed, FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106, OSHA Compliant 29 CFR 1926.152 | Red , Yellow , Blue , Green | 0000000 | 00000 | ——— | 0 | ——— | 0 | |

| C | 1 gal. | 9 1/2" | 11" | 1 5/8" | UL Listed, C-UL Listed, FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red , Yellow , Blue , Green | 000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | |

| C | 2 gal. | 9 1/2" | 13 3/4" | 1 5/8" | UL Listed, C-UL Listed, FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red , Yellow , Blue , Green | 00000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| C | 2 1/2 gal. | 11 3/4" | 11 1/2" | 1 5/8" | UL Listed, C-UL Listed, FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red , Yellow , Blue , Green | 00000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| C | 5 gal. | 12 1/2" | 16 1/2" | 1 5/8" | UL Listed, C-UL Listed, FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red , Yellow , Blue , Green | 00000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

Polyethylene

|  |

Style F | Style G |

Style | Cap. | Dia. | Lg. | Wd. | Ht. | Fill Opening Dia. | Certification | Color | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| F | 64 fl. oz. | — | 7 3/4" | 4 3/4" | 9 1/2" | 1 5/8" | FM Approved | Red | 0000000 | 000000 | |

| F | 1 gal. | — | 7 3/4" | 4 3/4" | 12 3/4" | 1 5/8" | FM Approved | Red | 0000000 | 000000 | |

| G | 2 1/2 gal. | 10 3/4" | — | — | 14 1/4" | 1 5/8" | UL Listed, FM Approved | Red | 0000000 | 000000 | |

| G | 5 gal. | 12 3/4" | — | — | 16" | 1 5/8" | UL Listed, FM Approved | Red | 0000000 | 000000 |

Safety Cans with Faucet

Powder-Coated Steel

Faucet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Dia. | Ht. | Fill Opening Dia. | Material | Outlet Thread Size | Outlet Thread Type | Seal Material | Certification | Flammability Rating | Color | Each | ||

| 5 | 11 3/4" | 17" | 1 1/2" | Brass | 13/16"-27 | UNS | PTFE | FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red | 0000000 | 0000000 | |

316 Stainless Steel

Faucet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Dia. | Ht. | Fill Opening Dia. | Material | Outlet Thread Size | Outlet Thread Type | Seal Material | Certification | Flammability Rating | Each | ||

| 5 | 11 1/4" | 16" | 1 1/2" | 316 Stainless Steel | 7/8"-27 | UNS | PTFE | FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106, OSHA Compliant 29 CFR 1926.152 | 0000000 | 0000000 | |

Polyethylene

Faucet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Dia. | Ht. | Fill Opening Dia. | Material | Outlet Thread Size | Outlet Thread Type | Seal Material | Certification | Flammability Rating | Color | Each | ||

| 5 | 13 1/2" | 17" | 1 1/2" | Brass | 1/2"-20 | UNF | PTFE | FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red | 0000000 | 0000000 | |

Safety Cans with Built-In Spout

Powder-Coated Steel

Cans | Replacement Spouts | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Spout | |||||||||||||||

Style | Cap., gal. | Dia. | Ht. | Fill Opening Dia. | Lg. | OD | Flexibility | Certification | UN Shipping Std. | Choose a Color | Each | Each | |||

| A | 1 | 9 1/2" | 10 1/2" | 1 1/2" | 9" | 5/8" | Flexible | UL Listed, C-UL Listed | — | Red , Yellow , Blue , Green | 0000000 | 0000000 | 0000000 | 000000 | |

| A | 2 1/2 | 11 1/2" | 12" | 1 1/2" | 9" | 5/8" | Flexible | UL Listed, C-UL Listed | — | Red , Yellow , Blue , Green | 0000000 | 000000 | 0000000 | 00000 | |

| A | 5 | 12 1/2" | 15 3/4" | 1 1/2" | 9" | 1" | Flexible | UL Listed, C-UL Listed | — | Red , Yellow , Blue , Green | 0000000 | 000000 | 0000000 | 00000 | |

| B | 2 1/2 | 11 3/4" | 12" | 1 1/2" | 9" | 5/8" | Flexible | FM Approved | UN1A1/Y1.2/100 | Red | 0000000 | 000000 | 0000000 | 00000 | |

| B | 5 | 11 3/4" | 17 1/2" | 1 1/2" | 9" | 1" | Flexible | FM Approved | UN1A1/Y1.2/100 | Red | 0000000 | 000000 | 0000000 | 00000 | |

Safety Cans with Stand

Powder-Coated Steel

Faucet | Base | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Dia. | Ht. | Fill Opening Dia. | Material | Outlet Thread Size | Outlet Thread Type | Seal Material | Lg. | Wd. | Ht. | Material | Certification | Flammability Rating | Color | Each | ||

| 5 | 11 3/4" | 16" | 1 1/2" | Brass | 13/16"-27 | UNS | PTFE | 15 3/4" | 15 3/4" | 11 3/4" | Steel | FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red | 0000000 | 0000000 | |

Polyethylene

Faucet | Base | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Dia. | Ht. | Fill Opening Dia. | Material | Outlet Thread Size | Outlet Thread Type | Seal Material | Lg. | Wd. | Ht. | Material | Certification | Flammability Rating | Color | Each | ||

| 5 | 13 1/2" | 17" | 1 1/2" | Brass | 1/2"-20 | UNF | PTFE | 15 3/4" | 15 3/4" | 11 3/4" | Steel | FM Approved | NFPA 30, OSHA Compliant 29 CFR 1910.106 | Red | 0000000 | 0000000 | |