How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

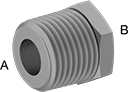

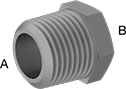

Low-Pressure Galvanized Iron and Steel Threaded Pipe Fittings

The galvanized finish on these fittings provides fair corrosion resistance. Fittings are for use in low-pressure applications.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: See table

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Flanges: Use Class 150 galvanized steel

Pipe Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| (A) | (B) | Pressure Class | Max. Pressure | Max. Steam Pressure | Material | Specifications Met | Each | |

NPT Male × NPT Female | ||||||||

| 1/4 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 00000 |

| 3/8 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 000 |

| 3/8 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 000 |

| 1/2 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 0000 |

| 1/2 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 0000 |

| 1/2 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 0000 |

| 3/4 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 3/4 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 3/4 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 3/4 | 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 0000 |

| 1 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 1 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 1 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 1 | 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 1 | 3/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 1 1/4 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 1 1/4 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 1 1/4 | 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 0000 |

| 1 1/4 | 3/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 0000 |

| 1 1/4 | 1 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 1 1/2 | 1/4 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 1 1/2 | 3/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 00000 |

| 1 1/2 | 1 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 00000 |

| 1 1/2 | 1 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 2 | 1/4 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 2 | 3/8 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 2 | 1 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 00000 |

| 2 | 1 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 00000 |

| 2 | 1 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Steel | ASME B16.14 | 00000000 | 00000 |

| 2 1/2 | 1/2 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 2 1/2 | 3/4 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 2 1/2 | 1 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 2 1/2 | 1 1/4 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 2 1/2 | 2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 3 | 1/2 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 3 | 3/4 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 3 | 1 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 3 | 1 1/4 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 3 | 1 1/2 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 4 | 1 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 000000 |

| 4 | 1 1/4 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 000000 |

| 4 | 1 1/2 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 000000 |

| 4 | 2 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 4 | 2 1/2 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 000000 |

| 4 | 3 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 4 | 3 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | ASME B16.14 | 00000000 | 00000 |

| 6 | 2 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 000000 |

| 6 | 3 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 000000 |

| 6 | 4 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 000000 |

| 3 1/2 | 1 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 3 1/2 | 1 1/4 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 3 1/2 | 1 1/2 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 3 1/2 | 2 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 3 1/2 | 3 | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

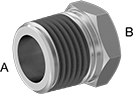

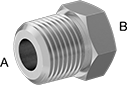

Low-Pressure Galvanized Iron and Steel Threaded Pipe Fittings with Sealant

The male threads on these fittings have a sealant applied for extra leak protection. Fittings are made of galvanized iron or steel, which have fair corrosion resistance. Also known as Pressure Class 125 or 150 fittings, they are for use in low-pressure applications.

Female x male 90° elbow adapters are also known as street elbows.

NPTF (Dryseal) threads are compatible with NPT threads.

- For Use With: Air, Oil, Natural Gas, Water

- Pressure Class: See table

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

Pipe Size | |||||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | Pressure Class | Max. Pressure | Max. Steam Pressure | Specifications Met | Each | |

NPT Male × NPT Female | |||||||

| 1 1/4 | 1/2 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 000000 |

| 1 1/4 | 3/4 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 1 1/4 | 1 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 1 1/2 | 1/2 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 1 1/2 | 3/4 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 1 1/2 | 1 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 1 1/2 | 1 1/4 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 2 | 3/4 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 2 | 1 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 2 | 1 1/4 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 2 | 1 1/2 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 2 1/2 | 2 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

| 3 | 2 | 125 | 125 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 00000 |

NPTF Male × NPTF Female | |||||||

| 1/4 | 1/8 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 0000 |

| 3/8 | 1/8 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 0000 |

| 3/8 | 1/4 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 0000 |

| 1/2 | 1/8 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 0000 |

| 1/2 | 1/4 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 0000 |

| 1/2 | 3/8 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 0000 |

| 3/4 | 1/4 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 0000 |

| 3/4 | 3/8 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 0000 |

| 3/4 | 1/2 | 150 | 150 psi @ 72° F | Not Rated | ASME B16.14 | 0000000 | 0000 |

| 1 | 1/4 | 150 | 150 psi @ 72° F | Not Rated | __ | 0000000 | 0000 |

| 1 | 1/2 | 150 | 150 psi @ 72° F | Not Rated | __ | 0000000 | 0000 |

| 1 | 3/4 | 150 | 150 psi @ 72° F | Not Rated | __ | 0000000 | 0000 |

- For Use With: Air, Oil, Natural Gas, Steam, Water

- Pressure Class: 150

- Specifications Met: ASME B16.3, ASTM A197, ASME B1.20.1, UL Listed

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Flanges: Use Class 150 galvanized steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Female × NPT Male | ||||

|---|---|---|---|---|

| 1/8 | 150 psi @ 72° F | 150 psi @ 350° F | 0000000 | 000000 |

| 1/4 | 150 psi @ 72° F | 150 psi @ 350° F | 0000000 | 00000 |

| 3/8 | 150 psi @ 72° F | 150 psi @ 350° F | 0000000 | 00000 |

| 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | 0000000 | 00000 |

| 3/4 | 150 psi @ 72° F | 150 psi @ 350° F | 0000000 | 00000 |

| 1 | 150 psi @ 72° F | 150 psi @ 350° F | 0000000 | 00000 |

| 1 1/4 | 150 psi @ 72° F | 150 psi @ 350° F | 0000000 | 00000 |

| 1 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | 0000000 | 00000 |

| 2 | 150 psi @ 72° F | 150 psi @ 350° F | 0000000 | 00000 |

- For Use With: Air, Oil, Natural Gas, Water

- Pressure Class: 150

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Flanges: Use Class 150 galvanized steel

- For Use With: Air, Oil, Natural Gas, Water

- Pressure Class: 150

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Flanges: Use Class 150 galvanized steel

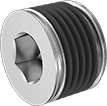

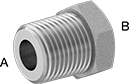

High-Pressure Galvanized Steel Threaded Pipe Fittings

A galvanized finish gives these fittings better corrosion resistance than our plain steel high-pressure fittings. Also known as Pressure Class 3000 fittings, they have excellent strength to handle high-pressure applications.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 3000

- Specifications Met: ASME B1.20.1, ASME B16.11, ASTM A105, ASTM B633

- Pipe Nipples and Pipe: Use Schedule 160 steel

Pipe Size | Dash Size | ||||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Max. Pressure | Max. Steam Pressure | Each | |

NPT Male × NPT Female | |||||||

| 1/4 | 1/8 | 04 | 02 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 3/8 | 1/8 | 06 | 02 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 0000 |

| 3/8 | 1/4 | 06 | 04 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 0000 |

| 1/2 | 1/4 | 08 | 04 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 0000 |

| 1/2 | 3/8 | 08 | 06 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 0000 |

| 3/4 | 3/8 | 12 | 06 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 0000 |

| 3/4 | 1/2 | 12 | 08 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 0000 |

| 1 | 1/2 | 16 | 08 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 0000 |

| 1 | 3/4 | 16 | 12 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 0000 |

| 1 1/4 | 1 | 20 | 16 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 0000 |

| 1 1/2 | 1 1/4 | 24 | 20 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 | 1/4 | 32 | 04 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 | 3/8 | 32 | 06 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 | 1/2 | 32 | 08 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 | 3/4 | 32 | 12 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 | 1 | 32 | 16 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 | 1 1/4 | 32 | 20 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 | 1 1/2 | 32 | 24 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 1/2 | 1 | 40 | 16 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 1/2 | 1 1/2 | 40 | 24 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 2 1/2 | 2 | 40 | 32 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 3 | 1 | 48 | 16 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 3 | 1 1/2 | 48 | 24 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 3 | 2 | 48 | 32 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 3 | 2 1/2 | 48 | 40 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 00000 |

| 4 | 2 | 64 | 32 | 3,000 psi @ 72° F | 300 psi @ 360° F | 00000000 | 000000 |

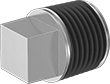

Compact Precision Extreme-Pressure Steel Threaded Pipe Fittings

Made to tighter tolerances than other steel pipe fittings, these are also known as instrumentation fittings. They are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are galvanized steel, which has fair corrosion resistance.

- For Use With: Air, Natural Gas, Water, Hydraulic Fluid

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108

Pipe Size | Dash Size | |||||

|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Max. Pressure | Each | |

NPT Male × NPT Female | ||||||

| 1/8 | 1/16 | 02 | __ | 6,000 psi @ 72° F | 00000000 | 000000 |

| 1/4 | 1/8 | 04 | 02 | 6,400 psi @ 72° F | 00000000 | 00000 |

| 3/8 | 1/8 | 06 | 02 | 6,800 psi @ 72° F | 00000000 | 00000 |

| 3/8 | 1/4 | 06 | 04 | 4,250 psi @ 72° F | 00000000 | 00000 |

| 1/2 | 1/8 | 08 | 02 | 5,250 psi @ 72° F | 00000000 | 00000 |

| 1/2 | 1/4 | 08 | 04 | 7,000 psi @ 72° F | 00000000 | 00000 |

| 1/2 | 3/8 | 08 | 06 | 4,500 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 1/4 | 12 | 04 | 5,100 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 3/8 | 12 | 06 | 4,350 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 1/2 | 12 | 08 | 4,350 psi @ 72° F | 00000000 | 00000 |

| 1 | 1/4 | 16 | 04 | 4,250 psi @ 72° F | 00000000 | 00000 |

| 1 | 3/8 | 16 | 06 | 4,250 psi @ 72° F | 00000000 | 00000 |

| 1 | 1/2 | 16 | 08 | 4,000 psi @ 72° F | 00000000 | 00000 |

| 1 | 3/4 | 16 | 12 | 3,750 psi @ 72° F | 00000000 | 00000 |

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are zinc-plated steel, which have better corrosion resistance than plain steel fittings.

NPTF (Dryseal) threads are compatible with NPT threads.

- For Use With: Air, Hydraulic Fluid, Water

- Specifications Met: ASTM A108

Pipe Size | Dash Size | ||||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Max. Pressure | Material | Each | |

NPTF Male × NPTF Female | |||||||

| 1/4 | 1/8 | 04 | 02 | 6,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 00000 |

| 3/8 | 1/8 | 06 | 02 | 6,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 3/8 | 1/4 | 06 | 04 | 6,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 1/2 | 1/8 | 08 | 02 | 6,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 1/2 | 1/4 | 08 | 04 | 6,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 1/2 | 3/8 | 08 | 06 | 6,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 3/4 | 1/4 | 12 | 04 | 5,500 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 3/4 | 3/8 | 12 | 06 | 5,500 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 3/4 | 1/2 | 12 | 08 | 5,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 1 | 1/4 | 16 | 04 | 4,500 psi @ 72° F | Zinc Plated Steel | 000000000 | 00000 |

| 1 | 3/8 | 16 | 06 | 4,500 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 1 | 1/2 | 16 | 08 | 4,500 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 1 | 3/4 | 16 | 12 | 4,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 0000 |

| 1 1/4 | 1 | 20 | 16 | 3,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 00000 |

| 1 1/2 | 1 | 16 | 08 | 4,500 psi @ 72° F | Zinc Plated Steel | 000000000 | 00000 |

| 2 | 1 | 32 | 16 | 2,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 00000 |

| 2 | 1 1/2 | 32 | 24 | 2,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 00000 |