Filter by

For Use With

Fitting Connection

Connects To

Measurement Unit

Pressure Scale Range

System of Measurement

Pressure Numeric Increments

Gender

Maximum Pressure

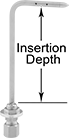

Insertion Depth

DFARS Specialty Metals

REACH

Export Control Classification Number (ECCN)

Minimum Pressure

Connection Material

Graduations

Accuracy Grade

Maximum Environment Temperature

Low-Pressure Differential Gauges with U-Tube

Brass Connections (Inches of Water)

Environment Temperature Change | Process Temperature Range | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure, in. H₂O | Pressure Scale Range | Pressure Numeric Increments, in. H₂O | Graduations, in. H₂O | Max. Pressure, psi | Ht. | Min. | Max. | Min. | Max. | Mount Type | For Use With | Accuracy | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Female Compression Tubes for 1/4" ODs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 8 | 4-0-4 In. of H₂O | 1 | 0.1 | 100 | 20" | Not Rated | Not Rated | Not Rated | Not Rated | Magnet | Air, Carbon Dioxide, Hydrogen, Argon | Not Rated | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 12 | 6-0-6 In. of H₂O | 1 | 0.1 | 100 | 25" | Not Rated | Not Rated | Not Rated | Not Rated | Magnet | Air, Carbon Dioxide, Hydrogen, Argon | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 16 | 8-0-8 In. of H₂O | 1 | 0.1 | 100 | 30" | Not Rated | Not Rated | Not Rated | Not Rated | Magnet | Air, Carbon Dioxide, Hydrogen, Argon | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 20 | 10-0-10 In. of H₂O | 1 | 0.1 | 100 | 34" | Not Rated | Not Rated | Not Rated | Not Rated | Magnet | Air, Carbon Dioxide, Hydrogen, Argon | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 24 | 12-0-12 In. of H₂O | 1 | 0.1 | 100 | 39" | Not Rated | Not Rated | Not Rated | Not Rated | Magnet | Air, Carbon Dioxide, Hydrogen, Argon | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 36 | 18-0-18 In. of H₂O | 1 | 0.1 | 100 | 58" | Not Rated | Not Rated | Not Rated | Not Rated | Magnet | Air, Carbon Dioxide, Hydrogen, Argon | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Differential Pressure Sensors

Compression Tube Flow Transmitters for Gases

Flow Transmitters | Voltage Adapters | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Flow Range, L/min | End-to-End Lg. | Accuracy | Max. Pressure @ Temp. | Temp. Range, ° F | Seal Material | Input Voltage Range, V DC | Mounting Position | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One 4-20 mA Analog Transmitter Output—2.1 mm Plug End ID Barrel Connection/DB9 Connection Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Body with Brass Fitting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0 to 0.01 | 5 1/8" | ±1.0% | 1,000 psi @ 70° F | 32 to 122 | Viton® Fluoroelastomer | 12 to 26 | Horizontal | 0000000 | 0000000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0 to 0.05 | 5 1/8" | ±1.0% | 1,000 psi @ 70° F | 32 to 122 | Viton® Fluoroelastomer | 12 to 26 | Horizontal | 0000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0 to 0.1 | 5 1/8" | ±1.0% | 1,000 psi @ 70° F | 32 to 122 | Viton® Fluoroelastomer | 12 to 26 | Horizontal | 0000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0 to 0.5 | 5 1/8" | ±1.0% | 1,000 psi @ 70° F | 32 to 122 | Viton® Fluoroelastomer | 12 to 26 | Horizontal | 0000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0 to 1 | 5 1/8" | ±1.0% | 1,000 psi @ 70° F | 32 to 122 | Viton® Fluoroelastomer | 12 to 26 | Horizontal | 0000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0 to 5 | 5 1/8" | ±1.0% | 1,000 psi @ 70° F | 32 to 122 | Viton® Fluoroelastomer | 12 to 26 | Horizontal | 0000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0 to 10 | 5 1/8" | ±1.0% | 1,000 psi @ 70° F | 32 to 122 | Viton® Fluoroelastomer | 12 to 26 | Horizontal | 0000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0 to 50 | 6 3/16" | ±1.0% | 1,000 psi @ 70° F | 32 to 122 | Viton® Fluoroelastomer | 12 to 26 | Horizontal | 0000000 | 00000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0 to 100 | 6 1/4" | ±1.0% | 1,000 psi @ 70° F | 32 to 122 | Viton® Fluoroelastomer | 12 to 26 | Horizontal | 0000000 | 00000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||