Filter by

Shaft Diameter

Body Material

Material

Export Control Classification Number (ECCN)

DFARS Specialty Metals

RoHS

Container Type

Dial Type

Operating System Compatibility

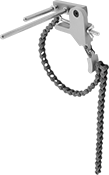

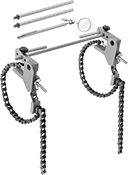

Shaft Alignment Chain Clamps

Body | Mounting | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Chain Lg. | Lg. | Wd. | Body Material | Hole Location | Fasteners Included | No. of Holes | Hole Thread Size | Includes | Each | ||

| 1" to 6" | 24" | 3 5/8" | 3/4" | Stainless Steel | Side | Yes | 3 | 1/4"-28 | ANSI No. 41 Chain (6" Dia. Capacity) One 5/16" Dia. × 3-1/4" Lg. Stainless Steel Holding Rod One 5/16" Dia. × 6-1/2” Lg. Stainless Steel Holding Rod | 00000000 | 0000000 | |

| 0" to 9" | 24" | 3" | 3" | Aluminum | — | — | — | — | ANSI No. 41 Chain (9” Dia. Capacity) One 5/16” Dia. × 3” Lg. Stainless Steel Holding Rod One 5/16” Dia. × 6” Lg. Stainless Steel Holding Rod | 0000000 | 000000 | |

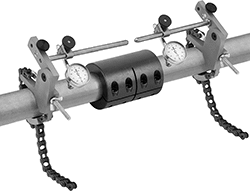

Dial-Indicator Shaft Alignment Chain Clamp Kits

Dial Indicator | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Dial Type | Plunger Location | Measuring Increments | Measurement Range | Container Type | Includes | Each | ||

| 0" to 9" | Continuous | Back | 0.001" | 0" to 0.2" | Case | Inspection Mirror Two Dial Indicators Two Swivel Clamps | 0000000 | 000000000 | |

| 0" to 9" | Balanced | Back | 0.001" | 0" to 0.2" | Case | Inspection Mirror Two Dial Indicators Two Swivel Clamps | 0000000 | 00000000 | |

| 0" to 9" | Balanced | Bottom | 0.001" | 0" to 0.3" | Case | Inspection Mirror Two Dial Indicators Two Swivel Clamps | 0000000 | 00000000 | |

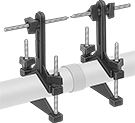

Shaft Alignment Chain Clamp Kits

|

For Shaft Dia. | Container Type | Includes | Each | ||

|---|---|---|---|---|---|

| 0" to 9" | Case | Inspection Mirror Two Chain Clamps | 0000000 | 0000000 |

Stylus-Indicator Shaft Alignment Clamp Kits

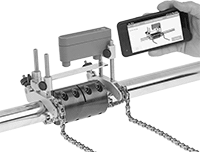

Proximity-Sensor Shaft Alignment Kits

Battery | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Max. Horiz. Clearance | Max. Coupling Ht. | Accuracy | Operating System Compatibility | Container Type | Includes | Type | Life, hr. | Enclosure Rating | Certificate Type | Cannot Be Sold To | Each | ||

| 7/8" to 6 1/4" | 7.3" | 2.2" | ±0.5° | Android 4.4.2 or Later iOS 9.0 or Later | Plastic Case | One Measuring Unit with Two Proximity Sensors Three Reference Bars (4", 6", and 8" Lg.) Two Chain Clamps One Tape Measure One USB Charging Cable | Rechargeable | 18 | IP54 | Calibration Certificate | California, Oregon | 0000000 | 000000000 | |