Filter by

Load Capacity

Attaching End Mount Type

Component

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Adjustment Movement

Any-Which-Way Positioning Arms

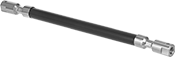

Threaded Hole/Threaded Stud Bases with Threaded Hole/Threaded Stud Attaching End

| |

End with Threaded Stud |

Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Projection | Base Mounting Thread Size | Max. Load Cap., lb. | Material | Color | Includes | Mounting Thread Size | Mounting Thread Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side to Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1/4"-20 | 4 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 1/4"-20 | UNC | 50035A21 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 1/4"-20 | 3.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 1/4"-20 | UNC | 50035A22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/4"-20 | 3 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 1/4"-20 | UNC | 50035A23 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 1/4"-20 | 2 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 1/4"-20 | UNC | 50035A24 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1/4"-20 | 2.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 1/4"-20 | UNC | 50035A25 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/4"-20 | 1.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 1/4"-20 | UNC | 50035A26 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 1/4"-20 | 0.8 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 1/4"-20 | UNC | 50035A31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 1/4"-20 | 0.6 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 1/4"-20 | UNC | 50035A32 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Stud Bases with Threaded Hole Attaching End

Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Projection | Base Mounting Thread Size | Max. Load Cap., lb. | Material | Color | Mounting Thread Size | Mounting Thread Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side to Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 5/8"-27 | 3 | Vinyl-Coated Steel | Black | 5/8"-27 | UNS | 50035A691 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13" | 5/8"-27 | 1 | Vinyl-Coated Steel | Black | 5/8"-27 | UNS | 50035A692 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19" | 5/8"-27 | 1 | Vinyl-Coated Steel | Black | 5/8"-27 | UNS | 50035A693 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Stud Bases with Threaded Stud Attaching End

Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Projection | Base Mounting Pipe Size | Max. Load Cap., lb. | Material | Color | Mounting Pipe Size | Mounting Thread Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side to Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 1/8 | 2 | Vinyl-Coated Steel | Black | 1/8 | NPSM | 50035A681 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 1/8 | 1 | Vinyl-Coated Steel | Black | 1/8 | NPSM | 50035A682 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/8 | 1 | Vinyl-Coated Steel | Black | 1/8 | NPSM | 50035A683 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Screw-On Bases with Plate Attaching End

Base | Attaching End | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Projection | Max. Load Cap., lb. | Material | Color | Mounting Fasteners Included | Lg. | Wd. | No. of Mounting Holes | Mounting Hole Dia. | Mounting Hole Dia. | Plate Lg. | Plate Wd. | No. of Mounting Holes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side to Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 5 | Vinyl-Coated Steel | Black | No | 2" | 3" | 3 | 13/64" | 3/16" | 2" | 1 7/8" | 8 | 1492A1 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Screw-On Bases with Threaded Hole/Threaded Stud Attaching End

| |

End with Threaded Stud |

Base | Attaching End | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Projection | Max. Load Cap., lb. | Material | Color | Mounting Fasteners Included | Lg. | Wd. | No. of Mounting Holes | Mounting Hole Dia. | Includes | Mounting Thread Size | Mounting Thread Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side to Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 3 | Vinyl-Coated Steel | Black | Yes | 2" | 1" | 2 | 0.275" | One 3/8"-16 Threaded Stud, Threadlocker | 3/8"-16 | UNC | 50035A33 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 3.5 | Vinyl-Coated Steel | Black | No | 2" | 1" | 2 | 0.275" | One 1/4"-20 Threaded Stud, Threadlocker | 1/4"-20 | UNC | 49985A29 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 2.5 | Vinyl-Coated Steel | Black | No | 2" | 1" | 2 | 0.275" | One 1/4"-20 Threaded Stud, Threadlocker | 1/4"-20 | UNC | 49985A31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 2.5 | Vinyl-Coated Steel | Black | No | 2" | 1" | 2 | 0.275" | One 3/8"-16 Threaded Stud, Threadlocker | 3/8"-16 | UNC | 49985A27 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1.5 | Vinyl-Coated Steel | Black | No | 2" | 1" | 2 | 0.275" | One 1/4"-20 Threaded Stud, Threadlocker | 1/4"-20 | UNC | 49985A32 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1.5 | Vinyl-Coated Steel | Black | No | 2" | 1" | 2 | 0.275" | One 3/8"-16 Threaded Stud, Threadlocker | 3/8"-16 | UNC | 49985A28 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp-On Bases with Threaded Hole Attaching End

Base | Attaching End | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Projection | For Max. Mounting Surface Thk. | Max. Load Cap., lb. | Material | Color | Lg. | Wd. | Mounting Thread Size | Mounting Thread Type | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side to Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 2" | 2.5 | Vinyl-Coated Steel | Black | 2" | 2" | 3/8"-16 | UNC | Padded Base Clamp | 49985A17 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 2" | 1.5 | Vinyl-Coated Steel | Black | 2" | 2" | 3/8"-16 | UNC | Padded Base Clamp | 49985A16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp-On Bases with Threaded Hole/Threaded Stud Attaching End

|  |

End with Threaded Stud |

Base | Attaching End | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Projection | For Max. Mounting Surface Thk. | Max. Load Cap., lb. | Material | Color | Lg. | Wd. | Includes | Mounting Thread Size | Mounting Thread Type | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side to Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 2" | 3 | Vinyl-Coated Steel | Black | 2" | 1 5/8" | One 3/8"-16 Threaded Stud, Threadlocker | 3/8"-16 | UNC | Padded Base Clamp | 50035A34 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 2" | 3.5 | Vinyl-Coated Steel | Black | 2 7/8" | 2" | One 1/4"-20 Threaded Stud, Threadlocker | 1/4"-20 | UNC | — | 49985A21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 2" | 2.5 | Vinyl-Coated Steel | Black | 2 7/8" | 2" | One 1/4"-20 Threaded Stud, Threadlocker | 1/4"-20 | UNC | — | 49985A22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 2" | 1.5 | Vinyl-Coated Steel | Black | 2 7/8" | 2" | One 1/4"-20 Threaded Stud, Threadlocker | 1/4"-20 | UNC | — | 49985A23 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Bases with Threaded Hole Attaching End

Magnetic Bases with Threaded Hole/Threaded Stud Attaching End

|  |

End with Threaded Stud |

Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Projection | Max. Pull, lbf | Max. Load Cap., lb. | Material | Color | Base Dia. | Includes | Mounting Thread Size | Mounting Thread Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotate, Tilt, Side to Side, In/Out | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 100 | 3 | Vinyl-Coated Steel | Black | 3" | One 3/8"-16 Threaded Stud, Threadlocker | 3/8"-16 | UNC | 50035A35 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 100 | 3.5 | Vinyl-Coated Steel | Black | 3 1/4" | One 1/4"-20 Threaded Stud, Threadlocker | 1/4"-20 | UNC | 49985A24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 100 | 2.5 | Vinyl-Coated Steel | Black | 3 1/4" | One 1/4"-20 Threaded Stud, Threadlocker | 1/4"-20 | UNC | 49985A25 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 100 | 1.5 | Vinyl-Coated Steel | Black | 3 1/4" | One 1/4"-20 Threaded Stud, Threadlocker | 1/4"-20 | UNC | 49985A26 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bend-and-Stay Positioning Arms

Arms

Base | Attaching End | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Projection | Dia. | Max. Load Cap., lb. | Material | Color | Mount Type | Mounting Thread Size | Mounting Hole Thread Type | Mounting Fasteners Included | Mount Type | Mounting Thread Size | Mounting Thread Type | Mounting Fasteners Included | Each | |||

| 6" | 5/8" | 20 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 3883N111 | 000000 | ||

| 9" | 5/8" | 7 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 3883N112 | 00000 | ||

| 12" | 5/8" | 5 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 3883N113 | 00000 | ||

| 18" | 5/8" | 3 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 3883N114 | 00000 | ||

| 24" | 5/8" | 2.5 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 3883N115 | 00000 | ||

| 30" | 5/8" | 2 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 3883N116 | 00000 | ||

| 36" | 5/8" | 0.5 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 3883N117 | 00000 | ||

Screw-On Bases

Arm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Lg. | Thk. | Max. Load Cap., lb. | Material | Color | Surface Mounting Fasteners Included | Mount Type | Mounting Fasteners Included | Each | |||

| 3" | 3" | 1/4" | 20 | Powder-Coated Steel | Black | Yes | Screw On | Yes | 3883N132 | 000000 | ||

Screw-On Right-Angle Bases

Arm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Lg. | Thk. | Max. Load Cap., lb. | Material | Color | Surface Mounting Fasteners Included | Mount Type | Mounting Fasteners Included | Each | |||

| 3" | 3" | 2" | 20 | Powder-Coated Steel | Black | Yes | Screw On | Yes | 3883N133 | 000000 | ||

Clamp-On Bases

For Max. Mounting Surface | Arm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Lg. | Thk. | Dia. | Max. Load Cap., lb. | Material | Color | Mount Type | Mounting Fasteners Included | Features | Includes | Each | |||

| 1 1/4" | 5 1/2" | 1 5/8" | — | 20 | Powder-Coated Steel | Black | Screw On | Yes | Padded Base Clamp | — | 3883N129 | 000000 | ||

| 1 7/8" | 8 1/4" | 2 5/8" | 2" | 20 | Powder-Coated Steel | Black | Screw On | Yes | Padded Base Clamp, Ratchet Handle | Rubber V-Block | 3883N131 | 00000 | ||

Magnetic Bases

Arm | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Dia. | Thk. | Max. Pull, lbf | Case Material | Mount Type | Mounting Fasteners Included | Each | |||

| 4 7/8" | 1/2" | 200 | Nickel-Plated Steel | Screw On | Yes | 3883N134 | 000000 | ||

Weighted Bases

Arm | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Dia. | Max. Load Cap., lb. | Material | Color | Mount Type | Mounting Fasteners Included | Each | |||

| 9" | 20 | Powder-Coated Steel | Black | Screw On | Yes | 3883N143 | 000000 | ||

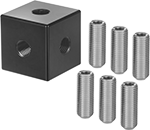

Multiarm Adapters

Base | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Lg. | Thk. | Max. Load Cap., lb. | Material | Color | Mount Type | Mounting Thread Size | Mounting Hole Thread Type | Includes | Each | |||

| 1 1/4" | 1 1/4" | 1 1/4" | 5 | Anodized Aluminum | Black | Threaded Hole, Threaded Stud | 3/8"-24 | UNF | Six 3/8"-24 Threaded Studs | 3883N144 | 000000 | ||

Spring Clamps

Attaching End | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Range of Motion | Max. Opening | Reach Lg. | Jaw Wd. | Lg. | Max. Load Cap., lb. | Material | Color | Mount Type | Mounting Thread Size | Mounting Thread Type | Mounting Fasteners Included | No. of Mounting Holes | Features | Each | |||

| 360° | 0.31" | 0.59" | 0.13" | 4 1/2" | 1 | Nickel-Plated Steel | — | Threaded Stud | 3/8"-24 | UNF | — | — | Locknut | 3883N124 | 000000 | ||

| — | 2" | 2" | 1" | 6 1/4" | 10 | Chrome-Plated Steel | — | Unthreaded Hole | — | — | Yes | 1 | Vinyl Grips | 3883N135 | 00000 | ||

| — | 3" | 3 3/4" | 6" | 8" | 10 | Plastic | Black | Unthreaded Hole | — | — | Yes | 3 | — | 3883N122 | 00000 | ||

| — | 3" | 4 1/2" | 3/8" | 8 1/2" | 10 | Plastic | Black | Unthreaded Hole | — | — | Yes | 3 | — | 3883N121 | 00000 | ||

Three-Finger Clamps

Attaching End | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Range of Motion | Max. Opening | Reach Lg. | Lg. | Max. Load Cap., lb. | Material | Color | Mount Type | Mounting Thread Size | Mounting Thread Type | Features | Each | |||

| 360° | 3 5/8" | 2 1/2" | 6 3/4" | 5 | Powder-Coated Aluminum | Gray | Threaded Stud | 3/8"-24 | UNF | Locknut, Vinyl-Coated Fingers | 3883N123 | 000000 | ||

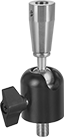

Ball-and-Socket Adapters

Attaching End | Arm Attaching End | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Range of Motion | Max. Tilt Range of Motion | Mounting Thread Size | Mounting Thread Type | Max. Load Cap., lb. | Body Material | Color | Mount Type | Mounting Thread Size | Mounting Thread Type | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 360° | 90° | 1/4"-20 | UNC | 6 | Anodized Aluminum | Black | Threaded Stud | 3/8"-24 | UNF | Locking Knob, Rubber-Padded Camera Seat | 3883N125 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball-and-Socket Connectors

Attaching End | Arm Attaching End | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Range of Motion | Max. Tilt Range of Motion | Mounting Thread Size | Mounting Thread Type | Mounting Fasteners Included | Max. Load Cap., lb. | Material | Color | Mount Type | Mounting Thread Size | Mounting Thread Type | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 7/8" | 360° | 90° | 3/8"-24 | UNF | Yes | 6 | Anodized Aluminum | Black | Threaded Stud | 3/8"-24 | UNF | Locking Knob | 3883N119 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Parallel Brackets

Attaching End | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Device Ht. | For Min. Device Wd. | Max. Load Cap., lb. | Material | Color | Mount Type | Mounting Fasteners Included | No. of Mounting Holes | Features | Each | |||

| 5 1/2" to 11 1/2" | 2" | 2 | Plastic | Black | Unthreaded Hole | Yes | 1 | Adjustable Arms | 3883N157 | 000000 | ||

Threaded Studs

Attaching End | ||||||||

|---|---|---|---|---|---|---|---|---|

Lg. | Material | Mount Type | Mounting Thread Size | Mounting Thread Type | Each | |||

| 1" | 303 Stainless Steel | Threaded Stud | 3/8"-24 | UNF | 3883N118 | 00000 | ||

Thread Adapters

Attaching End | Arm Attaching End | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Mounting Thread Size | Mounting Thread Type | Mounting Fasteners Included | Material | Mount Type | Mounting Thread Size | Mounting Thread Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 1/4"-20 | UNC | Yes | 303 Stainless Steel | Threaded Stud | 3/8"-24 | UNF | 3883N139 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 8-32 | UNC | Yes | 303 Stainless Steel | Threaded Stud | 3/8"-24 | UNF | 3883N137 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | M8 × 1.25 mm | Metric | Yes | 303 Stainless Steel | Threaded Stud | 3/8"-24 | UNF | 3883N141 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/16" | 5/8"-27 | UNS | — | 303 Stainless Steel | Threaded Stud | 3/8"-24 | UNF | 3883N146 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Right-Angle Thread Adapters

Arm Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Material | Attaching End Mounting Fasteners Included | Mount Type | Mounting Thread Size | Mounting Thread Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Unthreaded Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 303 Stainless Steel | Yes | Threaded Stud | 3/8"-24 | UNF | 3883N136 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Attaching-End Mounting Pads

Machine Guards

Attaching End | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Lg. | Thk. | Material | Color | Mount Type | Mounting Fasteners Included | No. of Mounting Holes | Includes | Each | |||

| 10" | 12" | 1/4" | Plastic | Clear | Unthreaded Hole | Yes | 2 | Right-Angle Thread Adapter | 3883N145 | 000000 | ||

Mirrors

Attaching End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Shape | Max. Range of Motion | Tilt Range of Motion | Dia. | Wd. | Lg. | Mirror Material | Material | Color | Mount Type | Mounting Thread Size | Mounting Thread Type | Mounting Fasteners Included | No. of Mounting Holes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Convex | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Round | 360° | 30° | 6 1/4" | — | — | Glass | Powder-Coated Steel | Black | Threaded Stud | 3/8"-24 | UNF | — | — | 3883N148 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Round | 360° | 30° | 8 1/2" | — | — | Glass | Powder-Coated Steel | Black | Unthreaded Hole | — | — | Yes | 1 | 3883N151 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flat | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rectangle | 360° | 30° | — | 5 1/2" | 7 1/2" | Glass | Powder-Coated Steel | Black | Threaded Stud | 3/8"-24 | UNF | — | — | 3883N149 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

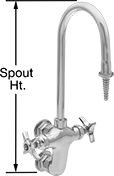

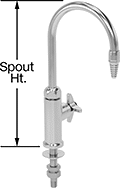

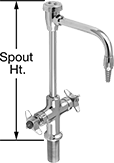

Extra-Clearance Double-Inlet Sink Faucets

|  |  |

Style A (Barbed Spout Outlet) | Style B (Barbed Spout Outlet) | Style C (Barbed Spout Outlet) |

|  | |

Style D | Style E |

Back Inlet—Wall Mount

Sink Faucets | Faucet Repair and Installation Kits | Replacement Hot Cartridges | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet | Spout | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Pipe Size | Thread Type | Flow Rate, gpm | Lg. | Ht. | Outlet Connection | For No. of Sink Faucet Holes | Inlet Hole Ctr.-to-Ctr. | Includes | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swivel Spout—Chrome-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/2 | NPT | 2.2 | 5 3/4" | 16 1/4" | — | 2 | 2 3/4" to 3 1/4" | Aerator | 2957K2 | 0000000 | 3773N11 | 000000 | 2346K46 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/2 | NPT | 3.8 | 5 3/4" | 16 1/4" | Barbed | 2 | 2 3/4" to 3 1/4" | — | 2957K4 | 000000 | 3773N11 | 00000 | 2346K46 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

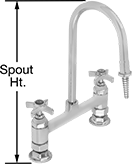

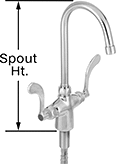

Bottom Inlet—Sink Mount

|  |  |  |

Style B (Barbed Spout Outlet) | Style C (Barbed Spout Outlet) | Style D | Style E |

Sink Faucets | Replacement Hot Cartridges | Replacement Cold Cartridges | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet | Spout | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Pipe Size | Thread Type | Flow Rate, gpm | Lg. | Ht. | Outlet Connection | For No. of Sink Faucet Holes | Inlet Hole Ctr.-to-Ctr. | Features | Food Industry Std. | Includes | Cannot Be Sold To | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Spout—Chrome-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/2 | NPT | 2.2 | 5 3/4" | 13 1/2" | — | 2 | 7 3/4" to 8 1/4" | — | — | Aerator | — | 2403K63 | 0000000 | 2346K46 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/2 | NPT | 3.8 | 5 3/4" | 13 1/2" | Barbed | 2 | 7 3/4" to 8 1/4" | — | — | — | — | 2403K64 | 000000 | 2346K46 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/2 | NPT | 2.2 | 5 1/2" | 12" | — | 2 | 7 3/4" to 8 1/4" | Backflow-Prevention Valve | — | Aerator | — | 2403K65 | 000000 | 2346K46 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/2 | NPT | 3.8 | 5 1/2" | 12" | Barbed | 2 | 7 3/4" to 8 1/4" | Backflow-Prevention Valve | — | — | — | 2403K66 | 000000 | 2346K46 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swivel or Fixed Spout—Chrome-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1/2 | NPS | 2.2 | 3 1/2" | 9 3/4" | — | 2 | 4" | — | NSF/ANSI 61, NSF/ANSI 372 | Aerator | California, Colorado, District of Columbia, Hawaii, Maine, Maryland, Massachusetts, New Jersey, New York, Oregon, Rhode Island, Vermont, Washington | 3050K41 | 000000 | 3081K51 | 00000 | 3081K52 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/2 | NPS | 2.2 | 5 1/4" | 11 3/4" | — | 3 | 8" | — | NSF/ANSI 61, NSF/ANSI 372 | Aerator | California, Colorado, District of Columbia, Hawaii, Maine, Maryland, Massachusetts, New Jersey, New York, Oregon, Rhode Island, Vermont, Washington | 3104K68 | 000000 | 3104K61 | 00000 | 3104K62 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

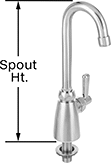

Single-Inlet Sink Faucets

Bottom Inlet—Sink Mount

|  |  |  |

Style E | Style F | Style G (Shown with Barbed Spout Outlet) | Style H (Shown with Barbed Spout Outlet) |

|  |  |  |

Style J (Shown with Barbed Spout Outlet) | Style K | Style L | Style M |

Sink Faucets | Replacement Hot/Cold Cartridges | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet | Spout | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | For Relative Water Temp. | No. of Faucet Supply Lines | Pipe Size | Thread Type | For Tube OD | Connection | Flow Rate, gpm | Lg. | Ht. | Outlet Connection | For No. of Sink Faucet Holes | Features | Includes | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Spout—Chrome-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | Hot, Cold | 1 | 1/2 | NPT | — | — | 3.8 | 5 3/4" | 14 1/4" | Barbed | 1 | — | 1/4 NPT Male Adapter | 2842K51 | 0000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Spout—PVC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | Hot, Cold | 1 | 3/8 | NPT | — | — | 3.8 | 6 1/4" | 14" | Barbed | 1 | — | — | 2859K12 | 000000 | 2859K14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | Hot, Cold | 1 | 3/8 | NPT | — | — | 3.8 | 6 1/4" | 14" | Barbed | 1 | Automatic Shutoff | — | 2859K13 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swivel or Fixed Spout—Chrome-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G | Cold | 1 | 1/4 | NPT | — | — | 3.3 | 6" | 12 3/4" | — | 1 | — | Aerator | 2952K392 | 000000 | 2952K42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G | Cold | 1 | 1/4 | NPT | — | — | 3.3 | 6" | 12 3/4" | Barbed | 1 | — | — | 2952K745 | 000000 | 2952K42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | Hot/Cold | 2 | — | — | 3/8" | Compression | 2.7 | 6" | 12 3/4" | — | 1 | — | Aerator | 2952K173 | 000000 | 2952K42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | Hot/Cold | 2 | — | — | 3/8" | Compression | 2.7 | 6" | 12 3/4" | Barbed | 1 | — | — | 2952K167 | 000000 | 2952K42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| J | Hot/Cold | 2 | — | — | 3/8" | Compression | 2.7 | 6" | 13 1/2" | — | 1 | Backflow-Prevention Valve | Aerator | 2952K305 | 000000 | 2952K42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| J | Hot/Cold | 2 | — | — | 3/8" | Compression | 2.7 | 6" | 13 1/2" | Barbed | 1 | Backflow-Prevention Valve | — | 2952K203 | 000000 | 2952K42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| K | Hot/Cold | 2 | — | — | 3/8" | Compression | 0.5 | 5 3/8" | 13 3/8" | — | 1 | — | — | 2198K112 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L | Hot, Cold | 1 | 1/2 | NPS | — | — | 0.5 | 3 1/2" | 11 1/2" | — | 1 | — | — | 2198K113 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swivel Spout—Chrome-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M | Hot/Cold | 2 | — | — | 3/8" | Compression | 1.5 | 8 1/4" | 17" | — | 1 | — | Extendable Faucet Sprayer | 2198K111 | 000000 | 2633K163 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Flow Double-Inlet Sink Faucets

Sink Faucets | Faucet Repair and Installation Kits | Replacement Hot Cartridges | Replacement Cold Cartridges | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Pipe Size | Thread Type | Gender | Flow Rate, gpm | Spout Lg. | For No. of Sink Faucet Holes | Inlet Hole Ctr.-to-Ctr. | Each | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Back Inlet—Wall Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swivel Spout—Chrome-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1/2 | NPT | Female | 23 | 5 3/4" | 2 | 7 3/4" to 8 1/4" | 2346K28 | 0000000 | 2500K111 | 000000 | 2346K46 | 000000 | 2346K44 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||