Wear-Resistant Press-Fit Drill Bushings

Made of durable tungsten carbide, these bushings outlast steel. Mount flush with jig plates for precise drilling. Drill bushings can also be used as spacers, shims, and machinery bushings.

Also Available: Other sizes. Please select 33455A999 and specify ID, OD, and length.

Tolerance | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | ID | OD | Lg. | Drill Bushing Type | Material | Hardness | Each | |

0.0938" ID | ||||||||||

| 13/64" | 1/2" | 3/32" | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 000000 |

0.125" ID | ||||||||||

| 1/4" | 5/16" | 1/8" | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

| 1/4" | 1/2" | 1/8" | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

0.1875" ID | ||||||||||

| 5/16" | 1/2" | 3/16" | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

0.25" ID | ||||||||||

| 13/32" | 1/2" | 1/4", E | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

| 1/2" | 1/2" | 1/4", E | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

0.3125" ID | ||||||||||

| 1/2" | 1/2" | 5/16" | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

| 1/2" | 1" | 5/16" | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

| 5/8" | 3/4" | 5/16" | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

0.5" ID | ||||||||||

| 3/4" | 1/2" | 1/2" | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

| 3/4" | 3/4" | 1/2" | 0.0001" to 0.0005" | 0.0013" to 0.0018" | -0.01" to 0.01" | PC | Tungsten Carbide | Rockwell A89 | 000000000 | 00000 |

Modular Scanning Probes for CMMs

Determine a part’s precise shape, position, and size—these Renishaw probes give you comprehensive 3D measurements by continuously gathering data as they move across your part. This means that unlike touch-trigger probes, they can follow the shape of complex features, such as angles and curves. And because they collect more data points than touch-trigger probes, they’re better for engine cylinder bores, dies, and other components that require high accuracy to fit into other parts. These probes are more accurate than other automated measurement systems that use light or cameras instead of touch.

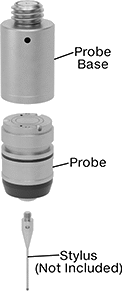

To inspect different features, you can swap them out for a different probe without having to recalibrate. They mount magnetically to a base that threads into your coordinate measuring machine (CMM), making mid-inspection changes quick. They’re also known as modules.

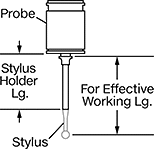

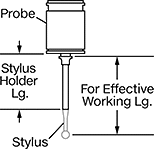

All probes require a stylus, a stylus holder, and a base. Choose a probe based on how long your stylus needs to be. These probes are highly sensitive to length, so you should make sure that the combined length of your holder and stylus falls within the probe’s effective working length range. If you want to use the same probe with multiple styli, you can use multiple holders. However, you can’t mix and match probes with different stylus holders.

Probe and base kits give you a basic setup that’s suitable for most measuring applications.

Non-linear scanning probes work with angled styli and star styli, which probe in multiple directions.

Bases house the system that sends a signal to record a measurement. They attach to quick-connect CMM probe heads.

For Stylus | ||||||||

|---|---|---|---|---|---|---|---|---|

| No. of Pieces | Includes | For Effective Working Lg., mm | Thread Size | O'all Lg., mm | For Axis Measuring Direction | Manufacturer (Series) | Each | |

| 4 | One SM25-1 Probe Two SH25-1 Stylus Holders One SP25M Probe Base | 20-50 | M3 | 20-50 | ±X, ±Y, ±Z | Renishaw (SM25-1, SH25-1, SP25M) | 0000000 | 0000000000 |

Probes | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

For Stylus | Stylus Holders | ||||||||||

| For Effective Working Lg., mm | Dia., mm | Lg., mm | Thread Size | O'all Lg., mm | For Axis Measuring Direction | Manufacturer (Series) | Each | Lg., mm | Each | ||

Probes | |||||||||||

| 20-50 | 25 | 26 | M3 | 20-50 | ±X, ±Y, ±Z | Renishaw (SM25-1) | 0000000 | 000000000 | 2.3 | 0000000 | 0000000 |

| 50-105 | 25 | 34 | M3 | 20-75 | ±X, ±Y, ±Z | Renishaw (SM25-2) | 0000000 | 00000000 | 32.2 | 0000000 | 000000 |

| 120-200 | 25 | 48 | M3 | 20-100 | ±X, ±Y, ±Z | Renishaw (SM25-3) | 0000000 | 00000000 | 102.2 | 0000000 | 000000 |

| 220-400 | 25 | 63 | M3 | 20-200 | ±X, ±Y, ±Z | Renishaw (SM25-4) | 0000000 | 00000000 | 202.3 | 0000000 | 000000 |

Non-Linear Scanning Probes | |||||||||||

| 10-100 | 25 | 39 | M3 | 10-100 | ±X, ±Y, ±Z | Renishaw (SM25-5) | 0000000 | 00000000 | 2.7 | 0000000 | 000000 |

Modular Probes for CMMs

Swap out Renishaw probe styles to inspect different features on a part without having to recalibrate. These probes mount magnetically to a base that threads into your coordinate measuring machine (CMM), making mid-inspection changes quick. They’re also known as modules. It’s easy to tell different styles apart from their different end colors. To take 3D measurements, they record the coordinates of different points on your workpiece. Because this involves physically touching your workpiece, they’re more accurate than other automated measurement systems. They’re touch-trigger probes, the most common CMM probe type, which means they stop to record the coordinates of one point at a time. Use them to check distances, diameters, right angles, and the location of holes and grooves. However, they're not as good at checking complex features, flatness, or roundness.

All probes require a stylus as well as a base (sold separately for some probes).

Trigger force is the amount of force required for a probe to take a measurement and record it. Choose a probe with a force that is high enough to avoid false triggers from vibration but not so high it damages the workpiece and leads to inaccurate measurements.

LF series probes have the lowest trigger force, so they’re best on materials such as rubber that could be deformed by too much pressure from probing. However, they’re the most likely to accidentally trigger from vibration.

SF series probes have a trigger force that works for most general purpose probing jobs where vibration is not an issue. 70 mm long and 95 mm long probes are useful if you need to reach deep into holes.

6W series probes work well if you need to inspect features on the bottom of a part, such as overhangs and undercuts. They measure in six directions instead of five.

MF series probes have a slightly higher trigger force than typical applications require to account for vibration.

EF series probes have the highest trigger force, so they’re the best choice for environments with vibration. They also work well for larger styli, such as long 5-star styli.

Bases house the system that sends a signal to record a measurement. They thread onto probe heads with an M8 connection on your CMM. TP20 probe bases have a magnetic proximity switch to prevent a probe from accidentally triggering when you’re attaching it or detaching it. However, probes attached to these bases can’t be used to inspect magnetic parts. Installation tools make it easier to thread a probe base onto your CMM.

For Stylus | Trigger Force, N | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Pieces | Includes | Dia., mm | Thread Size | O'all Lg., mm | For Axis Measuring Direction | X- and Y-Axis | Z-Axis | End Color | Features | Manufacturer (Series) | Each | |

| 3 | Two 20 mm Lg. SF Probes One 19 mm Lg. TP20 Probe Base | 13 | M2 | 10-50 | ±X, ±Y, +Z | 0.08 | 0.75 | Black | Magnetic Proximity Switch | Renishaw (SF, TP20) | 0000000 | 000000000 |

For Stylus | Trigger Force, N | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia., mm | Lg., mm | Thread Size | O'all Lg., mm | For Axis Measuring Direction | X- and Y-Axis | Z-Axis | End Color | Each | |

Renishaw LF | |||||||||

| 13 | 20 | M2 | 10-30 | ±X, ±Y, +Z | 0.055 | 0.65 | Green | 0000000 | 000000000 |

Renishaw SF | |||||||||

| 13 | 20 | M2 | 10-50 | ±X, ±Y, +Z | 0.08 | 0.75 | Black | 0000000 | 00000000 |

| 13 | 70 | M2 | 10-50 | ±X, ±Y, +Z | 0.08 | 0.75 | Black | 0000000 | 00000000 |

| 13 | 95 | M2 | 10-50 | ±X, ±Y, +Z | 0.08 | 0.75 | Black | 0000000 | 00000000 |

Renishaw 6W | |||||||||

| 13 | 24 | M2 | 10-30 | ±X, ±Y, ±Z | 0.14 | 1.6 | Blue | 0000000 | 00000000 |

Renishaw MF | |||||||||

| 13 | 20 | M2 | 10-60 | ±X, ±Y, +Z | 0.1 | 1.9 | Gray | 0000000 | 00000000 |

Renishaw EF | |||||||||

| 13 | 20 | M2 | 10-60 | ±X, ±Y, +Z | 0.1 | 3.2 | Brown | 0000000 | 00000000 |

| For Probe Manufacturer Series | Manufacturer | Manufacturer Model Number | Each | |

| TP20, TP20 NI | Renishaw | A-1042-1486 | 0000000 | 000000 |