Filter by

Head Weight

Handle Color

Face Color

Face Material

Face Mount Type

Face Shape

Face Hardness Rating

Handle Material

Head Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Handle Core Material

Color

Face Thread Size

Component

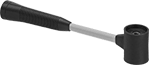

High-Visibility Dead Blow Mallets

Polyurethane Rubber Face

Head Wt., lb. | Face Dia. | Face Hardness Rating (Face Color) | Overall Lg. | Head Material | Handle Color | Handle Replaceable | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polyurethane Rubber Handle with Steel Core—Textured Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4 | 2" | Soft (Fluorescent Orange) | 12 7/8" | Polyurethane Rubber | Fluorescent Orange | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

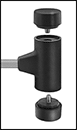

Create-Your-Own Mallets

Bodies with Screw-In Face Mount

|  |

Screw-In Face |

Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Head Wt., lb. | For Face Dia. | Thread Size | Thread Type | Overall Lg. | Head Material | Handle Replaceable | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fiberglass Handle with Textured Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4 | 2" | 3/8"-16 | UNC | 14" | Nylon | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

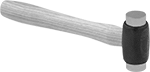

Replaceable-Face Mallets

Press-Fit Copper Face

|

Plain Grip |

Head Wt., lb. | Face Dia. | Overall Lg. | Head Material | Handle Replaceable | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ash Handle with Plain Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4 | 1 1/4" | 10 3/4" | Iron | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||