How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Metal Barbed Hose Fittings for Air and Water

Slide the barbed end into rubber hose and secure with the appropriate clamp or crimp-on hose ferrule.

Aluminum fittings are lighter in weight than other metal fittings. They have good corrosion resistance.

Fittings that swivel until tightened rotate 360° for easy installation. Fittings with a threaded end are also known as hose nipples.

Female NPSM (National Pipe Straight Mechanical) threads are compatible with male NPT and NPTF threads. Male NPSM threads are compatible with female NPSH threads.

- Maximum Pressure: See table

- Temperature Range: Brass Fittings: -40° to 160° F; Aluminum Fittings: -20° to 160° F

- Attachment Type: Use Band-and-Buckle Clamps

- Specifications Met: Brass Fittings: SAE J476

| For Hose ID | Pipe Size | Max. Pressure | Pkg. Qty. | Pkg. | |

Aluminum | |||||

|---|---|---|---|---|---|

| 6" | 6 | 25 psi @ 72° F | 1 | 0000000 | 000000 |

UN/UNF (SAE Straight)

Male Threads with Gasket

- Maximum Pressure: See table

- Temperature Range: Brass Fittings: -40° to 160° F; Aluminum Fittings: -20° to 160° F

- Attachment Type: See table

- Specifications Met: Brass Fittings: SAE J476

| For Hose ID | Pipe Size | Gasket Material | Max. Pressure | Attachment Type | Pkg. Qty. | Pkg. | |

Aluminum | |||||||

|---|---|---|---|---|---|---|---|

| 6" | 6 | Buna-N Rubber | 25 psi @ 72° F | Band-and-Buckle Clamp | 1 | 0000000 | 0000000 |

Easy-Fit Barbed Hose Fittings for Air and Water

Low-profile barbs and a longer first barb allow for a smoother, easier installation than other barbed fittings. Slide the barbed end into rubber hose and secure with a clamp.

Zinc-plated steel fittings are stronger and more durable than other metal fittings. They have fair corrosion resistance. Aluminum fittings are lighter in weight than other metal fittings. They have good corrosion resistance. Fittings with a threaded end are also known as hose nipples.

Hose connectors are also known as hose menders and splicers. Use them to connect lengths of hose or to repair damaged hose.

- Maximum Pressure: See table

- Maximum Vacuum: See table

- Temperature Range: -20° to 200° F

- Attachment Type: Use Worm-Drive Clamps, Bolt Clamps, or Band-and-Buckle Clamps

- Specifications Met: See table

- Maximum Pressure: See table

- Maximum Vacuum: See table

- Temperature Range: -20° to 200° F

- Attachment Type:

For 1/2" to 4" Hose IDs: Use Worm-Drive Clamps, Bolt Clamps, or Band-and-Buckle Clamps

For 6" to 8" Hose IDs: Use Band-and-Buckle Clamps - Specifications Met: See table

| For Hose ID | Max. Pressure | Max. Vacuum | Specifications Met | Each | |

Zinc-Plated Steel | |||||

|---|---|---|---|---|---|

| 6" | 100 psi @ 72° F | Not Rated | ASTM A513 | 00000000 | 0000000 |

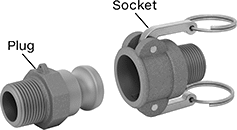

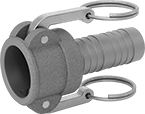

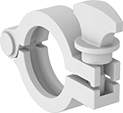

Metal Cam-and-Groove Hose Couplings for Water

A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

Aluminum couplings are lighter in weight than brass plugs and sockets. They have good abrasion and corrosion resistance thanks to their anodized finish.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Attachment Type: Use Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

Plugs with barbed end are also known as E adapters. Insert the barbed end into plastic or rubber hose and secure with a clamp.

| Coupling Size | Plug OD | For Hose ID | Max. Pressure | Each | |

Anodized Aluminum | |||||

|---|---|---|---|---|---|

| 6 | 6 15/16" | 6" | 75 psi @ 72° F | 0000000 | 0000000 |

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Attachment Type: Use Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

Straight sockets with barbed end are also known as C couplers. Insert the barbed end into plastic or rubber hose and secure with a clamp.

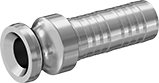

Metal Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of metal, these couplings have better durability than plastic cam-and-groove couplings. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug. Couplings are compatible with Andrews, Dixon, Ever-Tite, and PT cam-and-groove couplings.

Aluminum fittings are lighter in weight than 316 stainless steel fittings. They have good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Attachment Type: Use Band-and-Buckle Clamps

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: 6 Coupling Size and smaller: Fed. Spec. A-A-59326

Plugs with barbed end are also known as E adapters. Insert the barbed end into plastic or rubber hose and secure with a clamp.

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Attachment Type: Use Band-and-Buckle Clamps

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: 6 Coupling Size and smaller: Fed. Spec. A-A-59326

Straight sockets with barbed end are also known as C couplers. Insert the barbed end into plastic or rubber hose and secure with a clamp.

Sockets | Replacement Gaskets | Replacement Levers | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coupling Size | Socket ID | For Hose ID | Dash Size | No. of Levers | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Aluminum with Brass Levers | |||||||||||||

| 6 | 6 15/16" | 6" | 96 | 2 | Zinc-Plated Steel | 75 psi @ 72° F | 00000000 | 0000000 | 5 | 0000000 | 000000 | 000000000 | 000000 |

Aluminum with 304 Stainless Steel Levers | |||||||||||||

| 6 | 6 15/16" | 6" | 96 | 2 | 300 Series Stainless Steel | 75 psi @ 72° F | 0000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

316 Stainless Steel with 304 Stainless Steel Levers | |||||||||||||

| 6 | 6 15/16" | 6" | 96 | 2 | 300 Series Stainless Steel | 75 psi @ 72° F | 00000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

Easy-Fit Barbed Hose Fittings for Chemicals

Low-profile barbs and a longer first barb allow for a smoother, easier installation than other barbed fittings. Slide the barbed end into rubber hose and secure with a clamp. Fittings are 316 stainless steel, which has excellent corrosion resistance to withstand a variety of chemicals.

Adapters are also known as hose nipples; they adapt a barbed end to a threaded end.

- For Use With: Acetone, Isopropyl Alcohol, Mineral Oil, Sodium Hydroxide

- Maximum Pressure: See table

- Maximum Vacuum: 26 in. of Hg @ 72° F

- Temperature Range: -20° to 200° F

- Attachment Type: Use Worm-Drive Clamps, Bolt Clamps or Band-and-Buckle Clamps

- Specifications Met: ASME B1.20.1, ASTM A312

| For Hose ID | Pipe Size | Body Shape | Max. Pressure | Each | |

316 Stainless Steel | |||||

|---|---|---|---|---|---|

| 6" | 6 | Round | 25 psi @ 72° F | 0000000 | 0000000 |

- For Use With: Acetone, Isopropyl Alcohol, Mineral Oil, Sodium Hydroxide

- Maximum Pressure: See table

- Maximum Vacuum: 26 in. of Hg @ 72° F

- Temperature Range: -20° to 400° F

- Attachment Type: Use Worm-Drive Clamps, Bolt Clamps or Band-and-Buckle Clamps

- Specifications Met: ASTM A312

| For Hose ID | Pipe Size | Body Shape | Max. Pressure | Each | |

316 Stainless Steel | |||||

|---|---|---|---|---|---|

| 6" | 6 | Round | 25 psi @ 72° F | 0000000 | 0000000 |

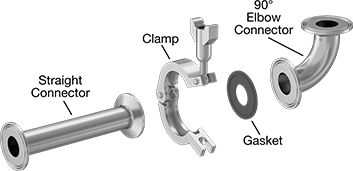

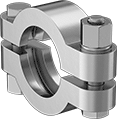

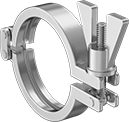

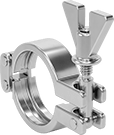

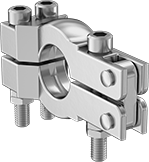

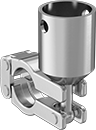

High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets

The smooth finish inside these fittings makes it easy to remove product residue. Also known as aseptic and tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for a fast and easy way to access your line. The pressure rating of the fitting will vary depending on the clamp you choose, and the temperature rating will vary based on the gasket material you choose.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

- For Use With:

3-A Certified Fittings: Air, Beverage, Food, Water

All Other Fittings: Air, Water - Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

- Specifications Met: See table

Fittings with barbed hose end connect flexible hose or tubing to your system. Secure with a hose clamp (sold separately).

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 6" | 6.57" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | For Tube Specifications Met | Each | |

| 6" | 6.57" | 304 Stainless Steel | 300 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 6" | 6.57" | 430 psi @ 72° F | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 6" | 6.57" | 430 psi @ 72° F | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | Specifications Met | Each | |

| 6" | 6.57" | 316 Stainless Steel | 210 psi @ 72° F | ASME BPVC.VIII | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 6" | 6.57" | 430 psi @ 72° F | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 6" | 6.57" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 0000000 |

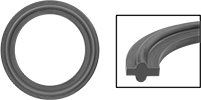

Buna-N gaskets are oil resistant. EPDM gaskets resist water and steam and work well in humid environments. Silicone gaskets withstand high temperatures. Fluoroelastomer gaskets stand up to fuel, oil, and acid condensates. PTFE gaskets withstand harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 6" | 5.820" | 6.510" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |

EPDM Rubber | ||||||||

| 6" | 5.820" | 6.670" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

Silicone Rubber | ||||||||

| 6" | 5.820" | 6.510" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

Fluoroelastomer Rubber | ||||||||

| 6" | 5.820" | 6.510" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

PTFE Plastic | ||||||||

| 6" | 5.820" | 6.510" | 0.19" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 00000 |