About Sleeving

More

About Metal Tubing

More

About Conduit

More

Smooth-Bore Seamless Stainless Steel Tubing

Seamless construction with no weld bead gives this tubing an interior with unrestricted flow. It is stronger than welded tubing and can be flared without splitting.

304 stainless steel has very good corrosion resistance.

316 stainless steel offers excellent corrosion resistance.

Tubing that meets ASTM specifications adheres to international standards for dimensions and materials.

- Temperature Range: See Table

- Bending Method: Tube Bender

- For Use With: Natural Gas, Water, Oil, Air

- Compatible Tubing Fittings: Butt Weld, Compression, Flared, and Yor-Lok

- Temperature Range:

304 Stainless Steel: -425° to 1500° F

316 Stainless Steel: -325° to 1500° F - Bending Method: Tube Bender

- For Use With: Natural Gas, Water, Oil, Air

- Compatible Tubing Fittings: Butt Weld, Compression, Flared, and Yor-Lok

Welded Stainless Steel Tubing

When your application does not require a smooth interior, this tubing is an economical choice. It has a weld bead on the inside.

304 stainless steel has very good corrosion resistance.

316 stainless steel offers excellent corrosion resistance.

- Temperature Range: 304 Stainless Steel: -420° to 1500° F

316 Stainless Steel: -320° to 1500° F - Bending Method: Tube Bender

- Compatible Tube Fittings: See table

| OD | Wall Thickness | ID | Maximum Pressure | Temper Rating | Compatible Tube Fittings | 1 ft. | 3 ft. | 6 ft. | |

304 Stainless Steel—For Use With Air, Deionized Water, Hydraulic Fluid, Natural Gas, Oil, Water | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4" | 0.065" | 0.12" | 8,100 psi @ 72° F | Soft | Butt Weld, Compression | 00000000 | |||

316 Stainless Steel—For Use With Air, Deionized Water, Hydraulic Fluid, Natural Gas, Oil, Water | |||||||||

| 1/4" | 0.065" | 0.12" | 8,100 psi @ 72° F | Soft | Butt Weld, Compression | 000000000 | |||

General Purpose Aluminum Tubing

- Temperature Range: -450° to 400° F

- Bending Method: Tube Bender

- Compatible Tube Fittings: Flared

This tubing is lightweight with good corrosion resistance and weldability. It has magnesium and silicon added for strength. Tubing is seamless, which provides a smooth interior for unrestricted flow. It can be flared without splitting.

General Purpose Copper Tubing

This tubing has good corrosion resistance and excellent heat transfer qualities. It is seamless, which provides a smooth interior for unrestricted flow. It can be flared without splitting. All tubing meets international standards for copper tubing.

Note: Copper tube size is an accepted industry designation, not an actual size.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -420° to 400° F

- Bending Method: By Hand

- Specifications Met: ASTM B75

- Compatible Tube Fittings: Compression and Solder Connect

Brass Tubing

Frequently used in a wide range of plumbing applications, this tubing holds up well in mildly corrosive environments. Tubing is seamless, so it has a smooth interior for unrestricted flow.

Smooth-Bore Seamless Steel Tubing

Seamless construction with no weld bead gives this tubing a smooth interior for unrestricted flow. It is stronger than welded tubing and can be flared without splitting. Do not use in corrosive environments.

- Temperature Range: See Table

- Bending Method: Tube Bender

- For Use With: Hydraulic Fluid, Natural Gas

- Compatible Tubing Fittings: Compression and Flared

High-Temperature Electrical-Insulating Tube Sleeving

This sleeving is often used to insulate connections in transformers, relays, and solenoids. It prevents electricity and heat from dissipating from wire and cable. When exposed to flame, it will self-extinguish and produce a nonconductive ash. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material. Made of silicone-coated fiberglass, it resists chemicals.

Electrical-Insulating Tube Sleeving

Add a layer of insulation to prevent electricity and heat from dissipating from wire and cable. This sleeving is often used in motors, transformers, and generators. Made of coated fiberglass, it resists abrasion, acids, alkalies, and chemicals.

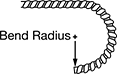

Acrylic-coated sleeving is more flexible than vinyl-coated sleeving, so it bends around tight corners. It resists solvents and oil.

Vinyl-coated sleeving resists wax and alcohol. Sleeving is flame-rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material.

Expandable Electrical-Insulating Tube Sleeving

A specially formulated silicone rubber coating allows this fiberglass sleeving to stretch over items during installation; it then tightens around its contents for a secure fit. Often used in motors, generators, and transformers, it prevents electricity and heat from dissipating from wire and cable. It has good chemical resistance.

Flexible Metal Conduit for Fiber Optic Cable

Protect fiber optic cable with this small-diameter conduit. Made of 304 stainless steel, it’s flexible enough to weave through tight spaces but strong enough to resist over-bending, so it won’t disrupt signals. Rated IP68, it’s dust tight and protected from prolonged submersion.

Conduit with a PVC cover is stretch resistant to protect cable from damage during installation. It also resists compression and impact for use in tight spaces that may shift over time, and resists UV light for use outdoors. This conduit does not resist oil or chemicals as well as conduit with a silicone cover.