About Sleeving

More

About Plastic and Rubber Tubing

More

Hard Plastic Tubing for Air and Water

This general purpose tubing has hard walls, yet is flexible enough for gradual bends. It has excellent strength and durability.

Nylon tubing can handle lower temperatures than polypropylene tubing and can withstand higher pressures. It has slightly softer walls than polypropylene tubing, making it more flexible and impact absorbent.

Opaque tubing doesn’t allow you to see what’s flowing through the line. Semi-clear tubing gives you a limited view inside the line.

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Rockwell R78)

- Temperature Range: -60° to 200° F

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Max. Vacuum | Lengths, ft. | Per Ft. | |

Inch | ||||||||

|---|---|---|---|---|---|---|---|---|

Black | ||||||||

| 9/32" | 3/8" | 3/64" | 1 1/2" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 00000 | |

Blue | ||||||||

| 9/32" | 3/8" | 3/64" | 1 1/2" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 0000 | |

Green | ||||||||

| 9/32" | 3/8" | 3/64" | 1 1/2" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 0000 | |

Red | ||||||||

| 9/32" | 3/8" | 3/64" | 1 1/2" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 0000 | |

Yellow | ||||||||

| 9/32" | 3/8" | 3/64" | 1 1/2" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 0000 | |

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Rockwell R78)

- Temperature Range: -60° to 200° F

Self-Retracting Hard Plastic Tubing for Air and Water

- Semi-Flexible

- Compatible with Barbed and Push to Connect Tube Fittings

- Hardness:

Inch: Hard (Rockwell R80)

Metric: Hard (Rockwell R75) - Temperature Range: -40° to 180° F

Keep your work area tidy with this coiled tubing that extends when you need it and retracts out of the way when you don’t. Tubing is made of tough and abrasion-resistant nylon. It is semi-flexible, so it is good for gradual bends.

Semi-clear tubing gives you a limited view inside the line. Opaque tubing doesn’t allow you to see what’s flowing through the line.

Note: Length refers to the length you can extend the tubing. Overstretching can cause the tubing to lose its ability to fully retract back to its normal state. Retracted length refers to the length of the tubing when coiled.

| ID | OD | Wall Thick. | Coil OD | Lg. | Retracted Lg. | Max. Pressure | Max. Vacuum | Each | |

Nylon Plastic | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Semi-Clear White | |||||||||

| 9/32" | 3/8" | 3/64" | 2 1/4" | 6 1/2 ft. | 6" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 000000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 17 1/2 ft. | 12" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 25 ft. | 17" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Black | |||||||||

| 9/32" | 3/8" | 3/64" | 2 1/4" | 6 1/2 ft. | 6" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 17 1/2 ft. | 12" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 25 ft. | 17" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Blue | |||||||||

| 9/32" | 3/8" | 3/64" | 2 1/4" | 6 1/2 ft. | 6" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 17 1/2 ft. | 12" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 25 ft. | 17" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Green | |||||||||

| 9/32" | 3/8" | 3/64" | 2 1/4" | 6 1/2 ft. | 6" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 17 1/2 ft. | 12" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 25 ft. | 17" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Orange | |||||||||

| 9/32" | 3/8" | 3/64" | 2 1/4" | 6 1/2 ft. | 6" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 17 1/2 ft. | 12" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 25 ft. | 17" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Red | |||||||||

| 9/32" | 3/8" | 3/64" | 2 1/4" | 6 1/2 ft. | 6" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 17 1/2 ft. | 12" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 9/32" | 3/8" | 3/64" | 2 1/4" | 25 ft. | 17" | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

UV-Resistant Hard Plastic Tubing for Chemicals

Ultraviolet light won’t cause this tubing to degrade or deteriorate.

FEP (fluorinated ethylene propylene) tubing is the most economical option.

Semi-clear tubing gives you a limited view inside the line. Opaque tubing does not allow you to see inside the line.

Semi-flexible tubing is good for gradual bends. Tubing that meets UL 94 V-0 is flame retardant, so it delays the spread of flames to valuable equipment.

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 55D)

- Temperature Range: 32° to 212° F

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 55D)

- Temperature Range: 32° to 212° F

Abrasion-Resistant Hard Plastic Tubing for Chemicals

This durable tubing has the best abrasion and wear resistance of all our hard tubing for chemicals. It can withstand a variety of acids and other harsh substances. Tubing is semi-clear, so you get a limited view inside the line. It is semi-flexible, so it’s good for gradual bends.

ETFE tubing can withstand a wider temperature range than PVDF tubing and can also handle vacuum applications. It has a super-smooth interior for unrestricted flow and easy cleaning. It meets ASTM D3159 specifications and testing requirements for material quality.

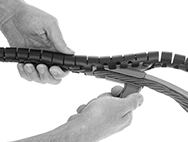

Slotted Spiral Sleeving

With a unique overlapping link structure, you can open and close this sleeving like a zipper using the included tool. The tool’s open design and the slots in the sleeving make it easy to branch off wires from your bundle as you’re zipping it shut. Thanks to its structure, this sleeving is better at resisting wear and tear than standard spiral sleeving. There are also no pinch points when it bends and flexes, so it’s great where there’s a lot of movement and vibration. Unlike cable ties and tape, it can be unwound and reused. Made of polypropylene, it resists chemicals and solvents.

As your setup changes, you can use the installation tool to add wire, cable, or hose to your sleeving without having to disassemble or move your equipment. That makes this sleeving ideal where frequent repair is necessary.

Note: The installation tool only works with slotted spiral sleeving, not other types of spiral sleeving.

100 ft. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | Expanded ID | OD | Wall Thick. | Includes | Temperature Range, °F | Specifications Met | Color | Each | |

Polypropylene Plastic | |||||||||

| 9/32" | 11/32" | 5/16" | 1/64" | Installation Tool | -75° to 230° | UL 94 HB | Black | 0000000 | 0000000 |