About Sleeving

More

About Plastic and Rubber Tubing

More

About Hose

More

High-Pressure Braided Chemical Hose with Male

Threaded and Precision Female Threaded Fittings

- Temperature Range: -65° to 400° F

- Maximum Vacuum: 28" of Hg @ 72° F

- Material: PTFE with 304 Stainless Steel Braid

- Female Fitting Swivels Until Tightened

For a more precise fit, hose has a 37° flare fitting on one end that has threads that adhere to tighter tolerances than other types of threads. This heavy duty hose is PTFE with a stainless steel braid for more chemical resistance and better strength than other chemical hose. Fittings that swivel until tightened are easy to install and are also known as JIC (Joint Industrial Council) fittings. These fittings meet SAE dimensional standard J514.

High-Pressure Braided Chemical Hose with Male

Threaded and Precision Male Threaded Fittings

- Temperature Range: -65° F to 400° F

- Maximum Vacuum: 28" of Hg @ 72° F

- Material: PTFE with 304 Stainless Steel Braid

For a more precise fit, hose has a 37° flare fitting on one end that has threads that adhere to tighter tolerances than other types of threads. This heavy duty hose is PTFE with a stainless steel braid for more chemical resistance and better strength than other chemical hose. Fittings that swivel until tightened are easy to install and are also known as JIC (Joint Industrial Council) fittings. These fittings meet SAE dimensional standard J514.

Soft Plastic Tubing for Air and Water

This general purpose PVC tubing is the industry standard for air and water applications. Tubing is clear, so you can easily monitor flow. It is flexible to easily bend around objects.

Masterkleer tubing is more economical than Tygon tubing. Tygon tubing has a nonabsorbing surface for improved flow and drainage.

- Flexible

- Compatible with Barbed Tube Fittings

- Hardness: Soft (Durometer 70A)

- Temperature Range: -40° to 140° F

Abrasion-Resistant Soft Rubber Tubing for Air and Water

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 45A)

- Temperature Range: -70° to 180° F

Thick, gum rubber walls give this tubing excellent abrasion resistance. It is opaque, so you can’t see what’s flowing through the line. Tubing is flexible to easily bend around objects.

Choose-a-Color Firm Plastic and Rubber Tubing for Air and Water

Multiple colors allow you to color-code your line for easy identification. Tubing is flexible, so it bends easily around objects.

PVC plastic tubing is more economical than polyurethane rubber tubing.

Opaque tubing doesn’t allow you to see what’s flowing through the line.

Abrasion-Resistant Firm Rubber Tubing for Air and Water

With excellent resistance to abrasion and tearing, this rubber tubing can hold up in rugged environments. It is semi-flexible, so it is good for gradual bends.

Polyurethane tubing is clear, so you can easily monitor flow through the line. Polyurethane tubing that is for use with air is ester based, so it should not be used with water or in humid environments. Polyurethane tubing that is for use with air and water is ether based, so it stays strong and durable even in wet environments.

Versilon polyurethane tubing can withstand lower temperatures than standard polyurethane and neoprene tubing. It was formerly known as Tygothane.

Hard Plastic Tubing for Vehicle Air Systems

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 65D)

- Temperature Range: -40° to 200° F

Safely power seat controls, horns, and other vehicle parts with compressed air. This tubing meets SAE or D.O.T. testing and performance standards for use in air-powered vehicle systems. It’s opaque, so you can’t see what’s flowing through the line. Semi-flexible, it’s good for gradual bends.

Tubing that meets D.O.T. FMVSS 106 is rated for use in motor vehicle brake systems. It’s also known as air brake tubing.

Soft Plastic Tubing for Food, Beverage, and Dairy

The industry standard for general purpose food, beverage, and dairy applications, this tubing meets NSF/ANSI Standard 51 for food contact. Tubing doesn’t contain plasticizers like DEHP, so it won’t impart tastes or odors to the fluid passing through it. It has a nonabsorbing surface, which makes it easy to clean. Tubing is clear, so you can easily monitor flow through the line. It is flexible, so it bends easily around objects.

PVC tubing is the most economical option.

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 70A)

- Temperature Range: -10° to 160° F

Soft Plastic Tubing for Chemicals

Use this general purpose PVC tubing with a variety of chemicals. Tubing is clear, so you can easily monitor flow. It is flexible, so it bends easily around objects.

Tygon PVC tubing can withstand a wider range of chemicals than standard PVC tubing. It has a super-smooth interior that resists product buildup better than standard PVC.

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 55A)

- Temperature Range: -20° to 160° F

Abrasion-Resistant Soft Rubber Tubing for Chemicals

Made of a blend of durable rubber, this rugged tubing can stand up to the wear and tear caused by abrasion. It has the chemical resistance to withstand a variety of acids and other harsh substances. It can also handle applications requiring repeated bending and flexing, such as metering (peristaltic) pumps and robotics. This tubing is opaque, so you cannot see inside the line to monitor flow. Semi-flexible, it is good for gradual bends. It’s commonly referred to as Tygon tubing, and used to be known as Norprene tubing.

Continuous-Flex Soft Rubber Tubing for Chemicals

- Flexible

- Compatible with Barbed Tube Fittings

- Hardness:

Inch: Soft (Durometer 65A)

Metric: Soft (Durometer 55A) - Temperature Range:

Inch: -70° to 245° F

Metric: -10° to 270° F

Commonly used in applications requiring movement, such as metering (peristaltic) pumps and robotics, this tubing can handle continuous bending and flexing. It has the chemical resistance to withstand a variety of acids and other harsh substances. Tubing is opaque, so you cannot see inside the line to monitor flow.

UV-Resistant Hard Plastic Tubing for Chemicals

Ultraviolet light won’t cause this tubing to degrade or deteriorate.

FEP (fluorinated ethylene propylene) tubing is the most economical option. Teflon® FEP tubing can handle lower temperatures than standard FEP tubing. It also withstands a wider range of chemicals than standard FEP and TPE tubing.

Semi-clear tubing gives you a limited view inside the line. Clear tubing allows you to easily monitor flow.

Semi-flexible tubing is good for gradual bends.

Tubing that meets USP Class VI adheres to specifications for material testing; it is not for use in medical applications. Tubing that meets ASTM D2116 and ASTM D3296 adheres to specifications and testing requirements for material quality.

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 60D)

- Temperature Range: -100° to 400° F

- See table for flexibility

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 55D)

- Temperature Range: -300° to 400° F

Extreme-Temperature Hard Plastic Tubing for Chemicals

- Semi-Flexible

- Compatible with Compression Tube Fittings

- Hard (Durometer 60D)

- Temperature Range: -100° to 500° F

Run acids, coolant, and other harsh chemicals through this PTFE tubing over a wide range of temperatures. It has a smooth interior for unrestricted flow and easy cleaning. Tubing is semi-flexible, so it is good for gradual bends. Not for use in medical applications.

PTFE tubing can be used in vacuum applications.

Teflon® PTFE tubing meets UL 94 V-0 for flame retardance, so it delays the spread of flames to valuable equipment.

Semi-clear tubing gives you a limited view inside the line.

Opaque tubing does not allow you to see inside the line.

Oil-Resistant Soft Rubber Tubing for Fuel and Lubricants

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 60A)

- Temperature Range: -20° to 212° F

With the best oil resistance of all our fuel and lubricant tubing, this Buna-N rubber tubing won’t deteriorate or become brittle when exposed to oil—even with long-term use. It is opaque, so you cannot see inside the line. Tubing is flexible, so it bends easily around objects.

Soft Plastic Tubing for Fuel and Lubricants

The industry standard for fuel and lubricant applications, this tubing can be used intermittently with petroleum-based products without becoming hard or brittle. Do not use with ethanol-based gasoline. It is flexible, so it bends easily around objects.

PVC tubing is the most economical option.

Tygon PVC tubing and tubing comparable to Tygon PVC can handle a wider temperature range than standard PVC tubing.

Clear tubing allows you to easily monitor flow. Semi-clear tubing gives you a limited view inside the line.

Hard Plastic Tubing for Fuel

Hard walls give this tubing the strength to handle high-pressure fuel and gasoline applications. It is nylon, which has excellent abrasion resistance. This tubing can be brittle, so take care as you're handling it. To ensure a good connection when installing fittings, trim damaged tube ends with a plastic tube cutter (sold separately).

Opaque tubing keeps you from seeing inside the tubing. This tubing is designed for high-temperature applications. It has a chemical-resistant nylon core that is reinforced with high-strength yarn. The protective nylon cover resists UV light.

- Flexible

- Compatible with Compression Tube Fittings

- Hard

- Temperature Range: -50° to 266° F

For OD | ||||

|---|---|---|---|---|

| Min. | Max. | Length | Each | |

| 1/8" | 3/4" | 4 1/2" | 0000000 | 000000 |

Spark-Resistant Tube Sleeving

A specially formulated silicone rubber coating on this fiberglass sleeving sheds sparks, molten metal splash, hydraulic fuel, and lubricating oil. Exposure to a torch will char the coating, but will not scorch the fiberglass inner layer. It also resists fraying. Because this sleeving is non-expandable, it does not stretch, so it’s best for applications where you know the exact diameter of the items you need to protect.

Extra-Thick Spark-Resistant Tube Sleeving

Made from thicker and denser fiberglass than standard spark-resistant sleeving, this sleeving is more abrasion resistant and provides better insulation. The specially formulated silicone rubber coating sheds sparks, molten metal splash, hydraulic fuel, and lubricating oil. It also resists fraying. Exposure to a torch will char the coating, but will not scorch the fiberglass inner layer. It can withstand short-term flame exposure up to 2000° F, and is flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test of vertically suspended material. Because this sleeving is non-expandable, it does not stretch, so it’s best for applications where you know the exact diameter of the items you need to protect.

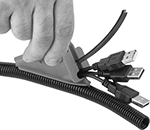

High-Strength Slit Corrugated Sleeving

Made of nylon, this sleeving is the most impact- and abrasion-resistant slit corrugated sleeving we offer. It resists acids and solvents. Wrap it around wire, cable, and hose without disconnecting them. It has a slit along the entire length that will not gap when flexing.

Slit Corrugated Sleeving with Closure Strip

Seal out dirt and dust better than standard slit sleeving—this sleeving secures shut with a closure strip. A slit along its entire length lets you install it around wire, cable, and hose that are already connected. Made of corrugated nylon, it resists wear and impact better than polyethylene sleeving and about as well as conduit. It’s ideal for high-traffic areas. It also resists acids and solvents, and it won’t crack from exposure to direct sunlight.

Speed up installation with the included tool, which routes cables and the rubber closure strip through the sleeving while closing the slit like a zipper. To use the tool, you have to disconnect your cables on one end. The tool holds plug ends while it pulls your cables through, so you don’t have to route bulky plugs through the sleeving.

32 ft. Lg. | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | Temperature Range, °F | Environmental Rating | Includes | Color | Each | |

Nylon Plastic with TPE Rubber Strip | |||||||

| 7/16" | 9/16" | -40° to 200° | IP50 | Installation Tool | Black | 0000000 | 000000 |

High-Strength Two-Piece Interlocking Corrugated Sleeving

Made of nylon, this sleeving stands up to scrapes and impact better than polyethylene sleeving, so it’s ideal for high-traffic areas. Since it’s corrugated, its impact and scrape resistance is similar to conduit, but it’s more flexible. It has two interlocking halves that nest into each other to fully enclose its contents, sealing it against dust and dirt—even when flexing. Often used instead of conduit, it has a long lifespan and is easier to install. Fit it around your wire, cable, or hose without having to disconnect them.

Because this sleeving is nylon, it also resists acids and solvents, and it won’t crack in direct sunlight. IP rated, it protects your components even in high-pressure, high-temperature washdowns.

Two-Piece Interlocking Corrugated Sleeving

The two halves of this sleeving nest into each other, fully enclosing contents. It has interlocking ridges that overlap to keep out dust and dirt, even when flexing. The corrugated construction gives it the impact and abrasion resistance of conduit, but with more flexibility.

Self-Extinguishing Spiral Sleeving

With a self-extinguishing additive, this sleeving will not produce fumes when exposed to open flame and high temperatures. Made of nylon, it also has good abrasion resistance. A reusable alternative to tape and cable ties, it allows you to route wire and cable between the spirals.

UV-resistant sleeving absorbs UV light, so it can be used in direct sunlight without getting damaged.

| ID | Expanded ID | OD | Wall Thick. | Temperature Range, °F | Specifications Met | Color | Each | |

10 ft. Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|

Nylon Plastic | ||||||||

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 000000 |

UV-Resistant Nylon Plastic | ||||||||

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Black | 00000000 | 00000 |

25 ft. Lg. | ||||||||

Nylon Plastic | ||||||||

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

UV-Resistant Nylon Plastic | ||||||||

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

50 ft. Lg. | ||||||||

Nylon Plastic | ||||||||

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 00000 |

UV-Resistant Nylon Plastic | ||||||||

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 00000 |

100 ft. Lg. | ||||||||

Nylon Plastic | ||||||||

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Clear | 00000000 | 000000 |

UV-Resistant Nylon Plastic | ||||||||

| 7/16" | 4" | 1/2" | 1/32" | -40° to 250° | UL Recognized Component | Black | 0000000 | 000000 |

Chemical-Resistant Spiral Sleeving

Made of PTFE, this sleeving has excellent resistance to chemicals, acids, salt water, and solvents. It meets UL 94 V-0 for flame retardance. A reusable alternative to tape and cable ties, it allows you to route wire and cable between the spirals.