About Plastic and Rubber Tubing

More

About Duct Hose

More

About Sleeving

More

About Hose

More

High-Temperature Coolant Hose

- Temperature Range: -65° to 350° F

- Material: Silicone Rubber

- Color: Blue

- For Clamp Type: Worm Drive

Silicone rubber gives this hose, often called radiator hose, the ability to handle high-heat conditions. Hose with steel wire reinforcement resists kinking.

High-Temperature Coolant Hose Elbows

- Temperature Range: -65° to 350° F

- Material: Silicone Rubber

- Color: Blue

- For Clamp Type: Worm Drive

Move coolant around tight turns in crowded spaces. Also known as radiator hose, these elbows are actually short lengths of hose that have been formed into an elbow. Made of silicone, they withstand high heat and are tough enough to stand up to wear and tear. They meet SAE J20R1 Class A, which is a performance and durability standard for hose in engine cooling systems.

Coolant Hose

- Temperature Range: 0° to 210° F

- Material: Buna-N Rubber

- Color: Black with Green Stripe

- For Clamp Type: Worm Drive

Commonly known as radiator hose, this hose is for low-pressure coolant applications.

Per Ft. | ||||||

|---|---|---|---|---|---|---|

| ID | OD | Max. Pressure | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

| 2 1/4" | 2 3/4" | 40 psi @ 72° F | 25 | 00000000 | 000000 | 000000 |

Flexible Coolant Hose

- Temperature Range: -20° to 210° F

- Maximum Vacuum: 28" of Hg @ 72° F

- Material: Buna-N Rubber with Neoprene Rubber Cover

- Color: Black with Yellow Stripe

- For Clamp Type: Worm Drive

With a tighter bend radius than other coolant hose, this hose can easily twist and turn around equipment.

Per Ft. | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

| 2 1/4" | 2 3/4" | 6 3/4" | 30 psi @ 72° F | 25 | 0000000 | 000000 | 000000 |

Extreme-Temperature Coolant Hose

- Temperature Range: -65° to 500° F

- Material: Silicone Rubber

- Color: Red

- For Clamp Type: Worm Drive

Reinforced by aramid fabric, this silicone rubber hose handles higher temperatures than any other coolant hose we offer. It’s designed to handle the heat of a turbocharged engine. The reinforcement also makes it last longer than standard silicone rubber coolant hose when exposed to extreme vibration.

| ID | OD | Max. Pressure | Internal Reinforcement | Lg., ft. | Each | |

| 2 1/4" | 2 1/2" | 30 psi @ 72° F | Aramid Fabric | 3 | 0000000 | 000000 |

Soft Plastic Tubing for Air and Water

This general purpose PVC tubing is the industry standard for air and water applications. Tubing is clear, so you can easily monitor flow. It is flexible to easily bend around objects.

Tygon tubing has a nonabsorbing surface for improved flow and drainage.

Static-Control Soft Plastic and Rubber Tubing for Air and Water

Protect sensitive equipment with this tubing—it is specially formulated to reduce the buildup of static electricity.

PVC plastic tubing has a steel wire coil embedded into the walls to divert static without the need for grounding. It is clear, so you can easily monitor flow. Tubing is semi-flexible and is good for gradual bends.

Abrasion-Resistant Soft Rubber Tubing for Air and Water

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 45A)

- Temperature Range: -70° to 180° F

Thick, gum rubber walls give this tubing excellent abrasion resistance. It is opaque, so you can’t see what’s flowing through the line. Tubing is flexible to easily bend around objects.

High-Pressure Hard Plastic Tubing for Air and Water

Excellent strength and durability allow this tubing to handle high-pressure air and water applications.

Polycarbonate tubing won’t degrade when exposed to the damaging effects of ultraviolet light. It should be used at temperatures above freezing. Tubing is clear, so you can easily monitor flow. It is rigid and does not bend.

- Rigid

- Compatible with Socket Connect Tube Fittings

- Hard (Rockwell R120)

- Temperature Range: 32° to 250°F

High-Pressure Soft Plastic and Rubber Tubing for Food, Beverage, and Dairy

An internal reinforcement gives this tubing the strength to withstand higher pressures than other soft tubing for food, beverage, and dairy. This hose meets NSF/ANSI food safety standards. Tubing doesn’t contain plasticizers like DEHP, so it won’t impart tastes or odors to the fluid passing through it.

PVC plastic tubing can withstand the highest pressures. It is clear, so you can easily monitor flow through the line. This tubing is 3A certified for use in dairy facilities and other sanitary environments. Flexible tubing bends easily around objects.

- See table for flexibility

- Compatible with Barbed Tube Fittings

- Soft (Durometer 70A)

- See table for temperature range

- Specifiications Met: See table

| ID | OD | Wall Thick. | Flexibility | Bend Radius | Temperature Range, °F | Max. Pressure | Max. Vacuum | Color | Specifications Met | Lengths, ft. | Per Ft. | |

Steel Wire Reinforced Inch Tubing | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 1/4" | 2 3/4" | 1/4" | Flexible | 9" | 25° to 150° | 50 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | 3-A Certified 62-02, NSF/ANSI 51, USP Class VI | 0000000 | 000000 | |

High-Temperature Flexible Duct Hose for Fumes

- Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Black or Red

- Temperature Range: Neoprene Coated: -65° to 300° F; Silicone Coated: -75° to 500° F

Combining the heat resistance of metal with the flexibility of fabric, this fiberglass hose has a special coating that stands up to high temperatures. Hose is for use with smoke, water-based paint fumes, and welding fumes.

Neoprene-coated hose meets UL 94 HB and UL 94 V-0 for flame retardance and can also handle sparks.

Silicone-coated hose handles a wider temperature range than neoprene-coated hose.

Warning: Hose should not be used for applications that generate a static charge.

Spiral | Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Specifications Met | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

Black Neoprene-Coated Fiberglass | ||||||||||||||

| 2 1/4" | 2 7/16" | 2 1/2" | 75% | 19 in. of Hg @ 72° F | 21 psi @ 72° F | 0.023" | Ribbed | Right Hand | Metal | UL 94 HB, UL 94 V-0 | 25 | 00000000 | 000000 | 000000 |

Red Silicone-Coated Fiberglass | ||||||||||||||

| 2 1/4" | 2 7/16" | 2 1/2" | 75% | 19 in. of Hg @ 72° F | 21 psi @ 72° F | 0.023" | Ribbed | Right Hand | Metal | __ | 25 | 00000000 | 00000 | 00000 |

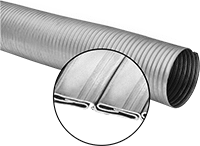

High-Temperature Rigid Metal Duct Hose for Fumes

- Rigid

- Compatible Clamps: U-Bolt Clamps

- Max. Temperature: Galvanized Steel: 750° F; Aluminum: 450° F; 304 Stainless Steel: 1500° F; 316 Stainless Steel: 1200° F

Metal interlocked strips create a rigid, durable hose that stays strong under high temperatures. Hose is for use with smoke, welding fumes, and oil fumes.

Galvanized steel offers fair corrosion resistance.

304 stainless steel has very good corrosion resistance.

| ID | OD | Bend Radius | Interior Surface Texture | Specifications Met | 5 ft. | 6 ft. | 7 ft. | 8 ft. | 9 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | |

Galvanized Steel | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

0.012" Material Thick. | ||||||||||||||

| 2 1/4" | 2 3/8" | 6 1/2" | Ribbed | __ | 0000000 | |||||||||

0.02" Material Thick. | ||||||||||||||

| 2 1/4" | 2 1/2" | 7 1/2" | Ribbed | __ | 0000000 | |||||||||

304 Stainless Steel | ||||||||||||||

0.012" Material Thick. | ||||||||||||||

| 2 1/4" | 2 3/8" | 6 1/2" | Ribbed | ASTM A240 | 0000000 | |||||||||

0.02" Material Thick. | ||||||||||||||

| 2 1/4" | 2 1/2" | 7 1/2" | Ribbed | ASTM A240 | 0000000 | |||||||||

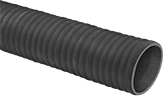

Blo-R-Vac Flexible Duct Hose for Dust

- Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Black, White, or Blue

- Temperature Range: -40° to 250° F

A good general purpose hose for blowing and vacuum applications, this hose is for use with grinding dust, sawdust, and lint.

TPR rubber hose meets UL 94 HB for flame retardance.

Warning: Hose should not be used for applications that generate a static charge.

Spiral | Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Specifications Met | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

Inch | ||||||||||||||

Black TPR Rubber | ||||||||||||||

| 2 1/4" | 2 1/2" | 2" | 50% | 29 in. of Hg @ 72° F | 30 psi @ 72° F | 0.03" | Ribbed | Left Hand | Metal | UL 94 HB | 25 | 000000000 | 00000 | 00000 |

White TPR Rubber | ||||||||||||||

| 2 1/4" | 2 1/2" | 2" | 50% | 29 in. of Hg @ 72° F | 30 psi @ 72° F | 0.03" | Ribbed | Left Hand | Metal | UL 94 HB | 25 | 000000000 | 0000 | 0000 |

High-Temperature Flexible Duct Hose for Dust

- Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Black

- Temperature Range: -60° to 300° F

The neoprene coating on this hose holds up under high heat. Hose meets UL 94 V-0 for flame retardance. It has a smooth interior for unrestricted flow. Hose is for use with lint, dust, and sawdust.

Warning: Hose should not be used for applications that generate a static charge.

Spiral | Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Specifications Met | Max. Continuous Lg., ft. | 1-11 | 12-Up | |

Neoprene-Coated Fiberglass | ||||||||||||||

| 2 1/4" | 2 5/16" | 2 1/2" | 75% | 19 in. of Hg @ 72° F | 21 psi @ 72° F | 0.024" | Smooth | Left Hand | Metal | UL 94 V-0 | 12 | 00000000 | 000000 | 000000 |

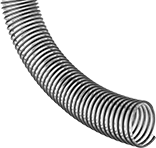

Extra-Strength High-Vacuum Duct Hose for Metal Chips and Shavings

- Rigid

- Compatible Clamps: Bolt Clamps

- Color: Black

- Temperature Range: -40° to 160° F

The strongest rubber duct hose we offer, this SBR (styrene butadiene rubber) hose is reinforced with yarn and has a metal spiral. Hose has a smooth interior for unrestricted flow.

Warning: Hose should not be used for applications that generate a static charge.

Spiral | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Vacuum | Material Thick. | Interior Surface Texture | Direction | Material | Max. Continuous Lg., ft. | Per Ft. | |

Per Foot | ||||||||||

SBR Rubber | ||||||||||

| 2 1/4" | 2 11/16" | 8" | 29 in. of Hg @ 72° F | 0.21" | Smooth | Right Hand | Metal | 50 | 0000000 | 000000 |

| Each | ||||||||||

Full Coil | ||||||||||

SBR Rubber | ||||||||||

| 2 1/4" | 2 11/16" | 8" | 29 in. of Hg @ 72° F | 0.21" | Smooth | Right Hand | Metal | 50 | 00000000 | 000000 |

Duct Hose with Wear Strip for Liquids

- Flexible

- Color: Clear; Wear Strip is Blue

- Temperature Range:-40° to 200° F

Run water, mist, oil, and other liquids through this hose. The wear strip protects the hose from damage caused by dragging.

Spiral | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Max. Continuous Lg., ft. | Per Ft. | |

Polyurethane | |||||||||||

| 2 1/4" | 2 13/16" | 4 13/16" | 28 in. of Hg @ 72° F | 40 psi @ 72° F | 0.055" | Ribbed | Left Hand | Plastic | 50 | 00000000 | 000000 |

Spark-Resistant Tube Sleeving

A specially formulated silicone rubber coating on this fiberglass sleeving sheds sparks, molten metal splash, hydraulic fuel, and lubricating oil. Exposure to a torch will char the coating, but will not scorch the fiberglass inner layer. It also resists fraying. Because this sleeving is non-expandable, it does not stretch, so it’s best for applications where you know the exact diameter of the items you need to protect.

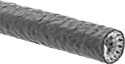

Abrasion-Resistant Sleeving

Tightly braided fibers give this sleeving excellent abrasion resistance. As it wears, the fibers frizz and make the outer wall thicker for improved protection. The interior is smooth to reduce snags during installation. It meets Mine Safety and Health Administration (MSHA) standards for fire protection in mines. Because this sleeving is non-expandable, it does not stretch, so it’s best for applications where you know the exact diameter of the items you need to protect.

Nylon sleeving is thicker than polyester sleeving, so it withstands contact with rougher surfaces. However, it can’t handle temperatures as high.

Spark-Resistant Hook-and-Loop Wrap-Around Sleeving

A specially formulated silicone rubber coats this fiberglass sleeving to shed sparks, molten metal splash, hydraulic fuel, and lubricating oil. Wrap it around wire, cable, and hose without disconnecting them. It has a slit along the entire length and a strip of hook-and-loop that keeps it securely closed but allows you to maintain access along the length of the sleeving.