About Sleeving

More

About Hose

More

About Duct Hose

More

Abrasion-Resistant Water Hose

- Temperature Range: -25° to 180° F

- Material: SBR Rubber

- Color: Black

- Compatible Hose Fittings: Cam-and-Groove

Made of SBR rubber, this hose and its cover are tough enough to resist wear and tear. Use it to transfer and discharge water.

For technical drawings and 3-D models, click on a part number.

Per Ft. | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Continuous Lg., ft. | 1-99 | 100-Up | |

| 3 1/2" | 4 1/16" | 35" | 150 psi @ 72° F | 100 | 0000000 | 000000 | 000000 |

High-Temperature Coolant Hose

- Temperature Range: -65° to 350° F

- Material: Silicone Rubber

- Color: Blue

- For Clamp Type: Worm Drive

Silicone rubber gives this hose, often called radiator hose, the ability to handle high-heat conditions. Hose with steel wire reinforcement resists kinking.

For technical drawings and 3-D models, click on a part number.

Coolant Hose

- Temperature Range: 0° to 210° F

- Material: Buna-N Rubber

- Color: Black with Green Stripe

- For Clamp Type: Worm Drive

Commonly known as radiator hose, this hose is for low-pressure coolant applications.

For technical drawings and 3-D models, click on a part number.

Per Ft. | ||||||

|---|---|---|---|---|---|---|

| ID | OD | Max. Pressure | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

| 3 1/2" | 4" | 25 psi @ 72° F | 25 | 00000000 | 000000 | 000000 |

Flexible Coolant Hose

- Temperature Range: -20° to 210° F

- Maximum Vacuum: 28" of Hg @ 72° F

- Material: Buna-N Rubber with Neoprene Rubber Cover

- Color: Black with Yellow Stripe

- For Clamp Type: Worm Drive

With a tighter bend radius than other coolant hose, this hose can easily twist and turn around equipment.

For technical drawings and 3-D models, click on a part number.

Per Ft. | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

| 3 1/2" | 4" | 14" | 20 psi @ 72° F | 25 | 0000000 | 000000 | 000000 |

Extreme-Temperature Coolant Hose

- Temperature Range: -65° to 500° F

- Material: Silicone Rubber

- Color: Red

- For Clamp Type: Worm Drive

Reinforced by aramid fabric, this silicone rubber hose handles higher temperatures than any other coolant hose we offer. It’s designed to handle the heat of a turbocharged engine. The reinforcement also makes it last longer than standard silicone rubber coolant hose when exposed to extreme vibration.

For technical drawings and 3-D models, click on a part number.

| ID | OD | Max. Pressure | Internal Reinforcement | Lg., ft. | Each | |

| 3 1/2" | 3 3/4" | 20 psi @ 72° F | Aramid Fabric | 3 | 0000000 | 000000 |

High-Temperature Flexible Duct Hose for Fumes

- Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Black or Red

- Temperature Range: Neoprene Coated: -65° to 300° F; Silicone Coated: -75° to 500° F

Combining the heat resistance of metal with the flexibility of fabric, this fiberglass hose has a special coating that stands up to high temperatures. Hose is for use with smoke, water-based paint fumes, and welding fumes.

Neoprene-coated hose meets UL 94 HB and UL 94 V-0 for flame retardance and can also handle sparks.

Silicone-coated hose handles a wider temperature range than neoprene-coated hose.

Warning: Hose should not be used for applications that generate a static charge.

For technical drawings and 3-D models, click on a part number.

Spiral | Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Specifications Met | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

Black Neoprene-Coated Fiberglass | ||||||||||||||

| 3 1/2" | 3 3/4" | 3 1/2" | 75% | 14 in. of Hg @ 72° F | 18 psi @ 72° F | 0.023" | Ribbed | Right Hand | Metal | UL 94 HB, UL 94 V-0 | 25 | 00000000 | 000000 | 000000 |

Red Silicone-Coated Fiberglass | ||||||||||||||

| 3 1/2" | 3 3/4" | 3 1/2" | 75% | 14 in. of Hg @ 72° F | 18 psi @ 72° F | 0.023" | Ribbed | Right Hand | Metal | __ | 25 | 00000000 | 00000 | 00000 |

Easy-Store Very Flexible Duct Hose for Fumes

- Very Flexible

- Compatible Clamps: Worm-Drive and Quick-Release Clamps

- Color: Orange

- Temperature Range: -65° to 550° F

If you’re tight on storage space, this hose compresses down to a small size. It is for use with smoke, water-based paint fumes, welding fumes, and oil fumes.

For technical drawings and 3-D models, click on a part number.

Spiral | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

Silicone-Coated Fiberglass | |||||||||||||

| 3 1/2" | 3 3/4" | 2 1/2" | 20% | 9 in. of Hg @ 72° F | 30 psi @ 72° F | 0.01" | Ribbed | Right Hand | Metal | 25 | 0000000 | 000000 | 000000 |

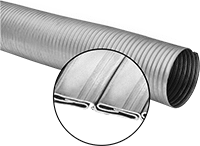

High-Temperature Rigid Metal Duct Hose for Fumes

- Rigid

- Compatible Clamps: U-Bolt Clamps

- Max. Temperature: Galvanized Steel: 750° F; Aluminum: 450° F; 304 Stainless Steel: 1500° F; 316 Stainless Steel: 1200° F

Metal interlocked strips create a rigid, durable hose that stays strong under high temperatures. Hose is for use with smoke, welding fumes, and oil fumes.

Galvanized steel offers fair corrosion resistance.

Aluminum is lighter than steel and has good corrosion resistance.

304 stainless steel has very good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| ID | OD | Bend Radius | Interior Surface Texture | Specifications Met | 5 ft. | 6 ft. | 7 ft. | 8 ft. | 9 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | |

Galvanized Steel | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

0.016" Material Thick. | ||||||||||||||

| 3 1/2" | 3 11/16" | 12" | Ribbed | __ | 0000000 | |||||||||

0.02" Material Thick. | ||||||||||||||

| 3 1/2" | 3 3/4" | 12 1/2" | Ribbed | __ | 0000000 | |||||||||

Aluminum | ||||||||||||||

0.02" Material Thick. | ||||||||||||||

| 3 1/2" | 3 3/4" | 12 1/2" | Ribbed | ASTM A463 | 00000000 | |||||||||

304 Stainless Steel | ||||||||||||||

0.012" Material Thick. | ||||||||||||||

| 3 1/2" | 3 5/8" | 11" | Ribbed | ASTM A240 | 0000000 | |||||||||

0.02" Material Thick. | ||||||||||||||

| 3 1/2" | 3 3/4" | 12 1/2" | Ribbed | ASTM A240 | 0000000 | |||||||||

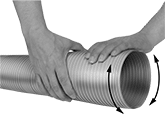

Adjustable-Diameter Rigid Duct Hose for Fumes

- Rigid

- Compatible Clamps: Worm-Drive Clamps

- Color: Gray

- Temperature Range: -10° to 150° F

Increase or decrease the hose diameter by up to 25% with a two-handed twist. Connect lengths of hose by interlocking two ends together. Hose is for use with smoke and water-based paint fumes.

For technical drawings and 3-D models, click on a part number.

| ID | OD | Fully Reduced ID | Fully Expanded ID | Bend Radius | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Max. Continuous Lg., ft. | Per Ft. | |

Per Foot | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

PVC | |||||||||||

| 3 1/2" | 3 3/4" | 2 5/8" | 4 3/8" | 8 1/2" | 6 in. of Hg @ 72° F | 2.5 psi @ 72° F | 0.187" | Ribbed | 25 | 0000000 | 000000 |

| Each | |||||||||||

Full Coil | |||||||||||

PVC | |||||||||||

| 3 1/2" | 3 3/4" | 2 5/8" | 4 3/8" | 8 1/2" | 6 in. of Hg @ 72° F | 2.5 psi @ 72° F | 0.187" | Ribbed | 25 | 00000000 | 000000 |

Blo-R-Vac Flexible Duct Hose for Dust

- Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Black, White, or Blue

- Temperature Range: -40° to 250° F

A good general purpose hose for blowing and vacuum applications, this hose is for use with grinding dust, sawdust, and lint.

TPR rubber hose meets UL 94 HB for flame retardance.

Warning: Hose should not be used for applications that generate a static charge.

For technical drawings and 3-D models, click on a part number.

Spiral | Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Specifications Met | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

Inch | ||||||||||||||

Black TPR Rubber | ||||||||||||||

| 3 1/2" | 3 13/16" | 5 1/2" | 50% | 20 in. of Hg @ 72° F | 10 psi @ 72° F | 0.03" | Ribbed | Left Hand | Metal | UL 94 HB | 25 | 000000000 | 00000 | 00000 |

White TPR Rubber | ||||||||||||||

| 3 1/2" | 3 13/16" | 5 1/2" | 50% | 20 in. of Hg @ 72° F | 10 psi @ 72° F | 0.03" | Ribbed | Left Hand | Metal | UL 94 HB | 25 | 000000000 | 0000 | 0000 |

High-Temperature Flexible Duct Hose for Dust

- Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Black

- Temperature Range: -60° to 300° F

The neoprene coating on this hose holds up under high heat. Hose meets UL 94 V-0 for flame retardance. It has a smooth interior for unrestricted flow. Hose is for use with lint, dust, and sawdust.

Warning: Hose should not be used for applications that generate a static charge.

For technical drawings and 3-D models, click on a part number.

Spiral | Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Specifications Met | Max. Continuous Lg., ft. | 1-11 | 12-Up | |

Neoprene-Coated Fiberglass | ||||||||||||||

| 3 1/2" | 3 5/8" | 3 1/2" | 60% | 14 in. of Hg @ 72° F | 18 psi @ 72° F | 0.024" | Smooth | Left Hand | Metal | UL 94 V-0 | 12 | 00000000 | 000000 | 000000 |

Blo-R-Vac Flexible Duct Hose with Wear Strip for Dust

- Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Black; Wear Strip is Orange

- Temperature Range: -40° to 180° F

This general purpose hose for blowing and vacuum applications has a thick PVC wear strip that protects against damage caused by dragging. Hose is for use with lint, dust, and sawdust. It meets UL 94 HB and UL 94 V-0 for flame retardance.

Warning: Hose should not be used for applications that generate a static charge.

For technical drawings and 3-D models, click on a part number.

Spiral | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Specifications Met | Max. Continuous Lg., ft. | Per Ft. | |

PVC-Coated Polyester | |||||||||||||

| 3 1/2" | 3 7/8" | 1 1/2" | 85% | 22 in. of Hg @ 72° F | 26 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | UL 94 HB, UL 94 V-0 | 25 | 0000000 | 00000 |

Abrasion-Resistant Very Flexible Duct Hose for Dust

- Very Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Clear or Black

- Temperature Range: -40° to 200° F

A blend of rubber and plastic creates a hose that's flexible, yet tough enough to handle abrasive particles such as grinding dust and sawdust.

Clear hose lets you see what's running through your line. It has a smooth interior for unrestricted flow.

Warning: Hose should not be used for applications that generate a static charge.

For technical drawings and 3-D models, click on a part number.

Spiral | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

Clear Polyurethane | |||||||||||||

| 3 1/2" | 3 7/8" | 3" | 55% | 14 in. of Hg @ 72° F | 6 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 00000000 | 00000 | 00000 |

Static-Control Very Flexible Duct Hose for Dust

- Very Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Black

- Specifications Met: UL 94 V-0

- Temperature Range: -40° to 250° F

The neoprene coating on this hose contains carbon to dissipate static when hose is installed in a grounded system. Hose is for use with lint, dust, and sawdust. It meets UL 94 V-0 for flame retardance.

Spiral | Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Surface Resistivity, ohms/sq. | Max. Continuous Lg., ft. | 1-49 | 50-Up | |

Neoprene-Coated Polyester | ||||||||||||||

| 3 1/2" | 3 13/16" | 2 1/2" | 35% | 25 in. of Hg @ 72° F | 21 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 103 | 50 | 0000000 | 000000 | 000000 |

Static-Control Duct Hose for Metal Chips and Shavings

- Flexible

- Color: Black

- Temperature Range: -40° to 140° F

SBR rubber is blended with carbon, which dissipates static electricity without the need for a grounding wire.

For technical drawings and 3-D models, click on a part number.

Spiral | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Surface Resistivity, ohms-cm | Max. Continuous Lg., ft. | 1-99 | 100-Up | |

SBR Rubber | |||||||||||||

| 3 1/2" | 4 1/8" | 4" | 29 in. of Hg @ 72° F | 30 psi @ 72° F | 0.138" | Smooth | Right Hand | Plastic | 107 | 100 | 0000000 | 000000 | 000000 |

Extra-Strength High-Vacuum Duct Hose for Metal Chips and Shavings

- Rigid

- Compatible Clamps: Bolt Clamps

- Color: Black

- Temperature Range: -40° to 160° F

The strongest rubber duct hose we offer, this SBR (styrene butadiene rubber) hose is reinforced with yarn and has a metal spiral. Hose has a smooth interior for unrestricted flow.

Warning: Hose should not be used for applications that generate a static charge.

Spiral | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Vacuum | Material Thick. | Interior Surface Texture | Direction | Material | Max. Continuous Lg., ft. | Per Ft. | |

Per Foot | ||||||||||

SBR Rubber | ||||||||||

| 3 1/2" | 4 1/16" | 10" | 29 in. of Hg @ 72° F | 0.265" | Smooth | Right Hand | Metal | 50 | 0000000 | 000000 |

| Each | ||||||||||

Full Coil | ||||||||||

SBR Rubber | ||||||||||

| 3 1/2" | 4 1/16" | 10" | 29 in. of Hg @ 72° F | 0.265" | Smooth | Right Hand | Metal | 50 | 00000000 | 00000000 |

Crush-Resistant Duct Hose for Liquids

- Flexible

- Temperature Range: 5290K and 9020T Series: -20° to 140° F; 5200K Series: 20° to 140° F

Step on this hose without causing damage. It is for use with water and chemicals such as citric acid.

For technical drawings and 3-D models, click on a part number.

Per Ft. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Vacuum | Max. Pressure | Interior Surface Texture | Color | Max. Continuous Lg., ft. | 1-49 | 50-Up | |

Polyethylene | ||||||||||

| 3 1/2" | 4" | 10" | 4 in. of Hg @ 72° F | 2 psi @ 72° F | Ribbed | Gray/Black | 50 | 0000000 | 000000 | 000000 |

Duct Hose Connectors

Slide these connectors into the ends of duct hose and secure with a clamp.

Aluminum is lightweight.

304 stainless steel offers very good corrosion resistance.

High-Temperature Electrical-Insulating Tube Sleeving

This sleeving is often used to insulate connections in transformers, relays, and solenoids. It prevents electricity and heat from dissipating from wire and cable. When exposed to flame, it will self-extinguish and produce a nonconductive ash. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material. Made of silicone-coated fiberglass, it resists chemicals.

Spark-Resistant Tube Sleeving

A specially formulated silicone rubber coating on this fiberglass sleeving sheds sparks, molten metal splash, hydraulic fuel, and lubricating oil. Exposure to a torch will char the coating, but will not scorch the fiberglass inner layer. It also resists fraying. Because this sleeving is non-expandable, it does not stretch, so it’s best for applications where you know the exact diameter of the items you need to protect.

Hook-and-Loop Wrap-Around Sleeving

A strip of hook-and-loop creates a strong seal along the entire length of this sleeving, yet it can be opened at any point to access contents. Wrap it around wire, cable, and hose without disconnecting them.

Nylon sleeving is made of tightly braided fibers for excellent abrasion resistance. It has the toughness of metal, yet remains flexible.

Spark-Resistant Hook-and-Loop Wrap-Around Sleeving

A specially formulated silicone rubber coats this fiberglass sleeving to shed sparks, molten metal splash, hydraulic fuel, and lubricating oil. Wrap it around wire, cable, and hose without disconnecting them. It has a slit along the entire length and a strip of hook-and-loop that keeps it securely closed but allows you to maintain access along the length of the sleeving.