How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Plastic and Rubber Tubing

More

About Metal Tubing

More

Soft Plastic Tubing for Air and Water

This general purpose PVC tubing is the industry standard for air and water applications. Tubing is clear, so you can easily monitor flow. It is flexible to easily bend around objects.

Masterkleer tubing is more economical than Tygon tubing. Tygon tubing has a nonabsorbing surface for improved flow and drainage.

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 65A)

- Temperature Range: -30° to 160° F

Static-Control Soft Plastic and Rubber Tubing for Air and Water

Protect sensitive equipment with this tubing—it is specially formulated to reduce the buildup of static electricity.

Silicone rubber tubing has carbon embedded into the walls to divert static quickly. It can handle a wider temperature range than PVC tubing, and is more flexible, so it bends easily around objects. It is opaque, so you can’t see what’s flowing through the line.

Super-Soft Rubber Tubing for Air and Water

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 40A)

- Temperature Range: 0° to 150° F

Stretch it, bend it, compress it—this tubing will spring back to its original shape. Made of latex rubber, it has a super-soft texture, yet offers excellent abrasion resistance. Tubing is opaque, so you cannot see what’s running through the line.

Continuous-Flex Soft Plastic Tubing for Air and Water

This PVC tubing can handle continuous bending and flexing in applications requiring movement, such as metering (peristaltic) pumps and robotics. Tubing is clear, so you can easily monitor flow through the line. It’s commonly referred to as Tygon tubing.

- Comparable to Tygon R-3603

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 55A)

- Temperature Range: -50° to 160° F

Flame-Retardant Soft Rubber Tubing for Air and Water

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 60A)

- Temperature Range: -70° to 450° F

This self-extinguishing, silicone rubber tubing meets UL 94 V-0 and UL 94 V-1 for flame retardance, so it delays the spread of flames to valuable equipment. It is opaque, so you cannot see what’s flowing through the line. Tubing is flexible to easily bend around objects.

Choose-a-Color Firm Plastic and Rubber Tubing for Air and Water

Multiple colors allow you to color-code your line for easy identification. Tubing is flexible, so it bends easily around objects.

Polyurethane rubber tubing can handle higher pressures than PVC plastic tubing and can also be used in vacuum applications. It is ether based, so it performs better in humid environments than ester-based polyurethane.

Opaque tubing doesn’t allow you to see what’s flowing through the line. Clear tubing allows you to easily monitor flow.

- Flexible

- Compatible with Barbed Tube Fittings and Push to Connect Tube Fittings

- Firm (Durometer 95A)

- Temperature Range: See table

- Flexible

- Compatible with Barbed Tube Fittings and Push to Connect Tube Fittings

- Firm (Durometer 95A)

- Temperature Range: See table

Joined Firm Rubber Tubing for Air and Water

- Flexible

- Compatible with Barbed Tube Fittings

- Firm (See table for hardness rating)

- Temperature Range: -40° to 160° F

Run multiple tubing lines together without the hassle of cable ties or tape. This tubing comes joined for a clean, organized look. It's flexible enough to easily bend around objects without kinking. No matter how you twist, bend, or stretch this tubing, it returns to its original shape. Made of ether-based polyurethane, it has excellent resistance to tearing and abrasion and stays strong and durable, even in humid environments.

Multicolor tubing can be peeled apart for applications that require fewer tubes.

Clear tubing allows you to monitor flow through the line. Opaque tubing does not let you see inside the line.

| No. of Joined Tubes | ID | OD | Wall Thick. | Hardness | Max. Pressure | Max. Vacuum | Lengths, ft. | Per Ft. | |

One each of Opaque Green and Opaque Yellow | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 | 5mm | 8mm | 1.5mm | Durometer 95A | 190 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 | |

One each of Opaque Green, Opaque Yellow, Opaque White, and Clear | |||||||||

| 4 | 5mm | 8mm | 1.5mm | Durometer 95A | 190 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 0000 | |

Self-Retracting Firm Rubber Tubing for Air and Water

- Flexible

- Compatible with Barbed Tube Fittings

- Firm (Durometer 95A)

- Temperature Range: -40° to 120° F

Keep your worksite safe and clutter free—this coiled polyurethane rubber tubing extends when you need it and retracts out of the way when you don’t. The material is ether based, so you’ll get the abrasion and tear resistance you’d expect from polyurethane, along with the ability to use it in humid environments. Tubing is flexible and bends easily around objects. It comes in multiple colors, so you can color-code your lines.

Clear tubing allows you to easily monitor flow. It has a colored tint. Opaque tubing doesn’t allow you to see what’s flowing through the line.

Note: Length refers to the length you can extend the tubing. Overstretching can cause the tubing to lose its ability to fully retract back to its normal state. Retracted length refers to the length of the tubing when coiled.

| ID | OD | Wall Thick. | Coil OD | Lg. | Retracted Lg. | Max. Pressure | Max. Vacuum | Each | |

Polyurethane Rubber | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Clear Blue | |||||||||

| 5mm | 8mm | 1.5mm | 48mm | 3 m | 178mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 000000 |

| 5mm | 8mm | 1.5mm | 48mm | 5 m | 305mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 10 m | 622mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Black | |||||||||

| 5mm | 8mm | 1.5mm | 48mm | 1 m | 51mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 3 m | 178mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 5 m | 305mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Blue | |||||||||

| 5mm | 8mm | 1.5mm | 48mm | 1 m | 51mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 3 m | 178mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 5 m | 305mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 10 m | 622mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Fluorescent Green | |||||||||

| 5mm | 8mm | 1.5mm | 48mm | 3 m | 178mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 5 m | 305mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 10 m | 622mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Red | |||||||||

| 5mm | 8mm | 1.5mm | 48mm | 1 m | 51mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 3 m | 178mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 5mm | 8mm | 1.5mm | 48mm | 10 m | 622mm | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

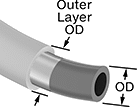

Weld-Spatter-Resistant Firm Rubber Tubing for Air and Water

- Semi-Flexible

- Compatible with Push to Connect Tube Fittings

- Hardness:

Inch: Firm (Durometer 95A)

Metric: Firm (Durometer 90A) - Temperature Range:

Inch: -40° to 165° F

Metric: 0° to 140° F

Designed for use in welding applications, this tubing is specially formulated to self-extinguish. It’s made of ether-based polyurethane, so it has excellent resistance to abrasion and tearing and stays strong and durable in humid environments. Tubing is opaque, so you cannot see what is flowing through the line. It is semi-flexible, which is good for gradual bends.

To attach fittings, use a cutting tool (sold separately) to strip away the outer layers of tubing. The tube OD dimension refers to the inner layer of tubing. Attach a protective cover (sold separately) to prevent weld spatter from getting between the tubing and fitting.

Metric tubing has three layers of material. It meets UL 94 V-2 for flame retardance.

Hard Plastic Tubing for Air and Water

This general purpose tubing has hard walls, yet is flexible enough for gradual bends. It has excellent strength and durability.

Semi-clear tubing gives you a limited view inside the line.

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Rockwell R93)

- Temperature Range: 40° to 200° F

Flame-Retardant Hard Plastic Tubing for Air and Water

This tubing is self-extinguishing to delay the spread of flames to valuable equipment. Tubing is opaque, so you cannot see what’s flowing through the line. It is semi-flexible, so it is good for gradual bends.

Nylon tubing can withstand higher pressures than polyethylene tubing. It meets UL 94 V-0 for better flame retardance than polyethylene tubing, and is best suited for spot-welding or other applications where sparks can occur.

- Semi-Flexible

- Compatible with Push to Connect Tube Fittings

- Hard (Durometer 50D)

- Temperature Range: 32° to 140° F

- Specifications Met: UL 94 V-0

Static-Control Hard Plastic Tubing for Air

- Semi-Flexible

- Compatible with Barbed, Compression and Push to Connect Tube Fittings

- Hard (Durometer 45D)

- Temperature Range: 35° to 100° F

To protect sensitive equipment, this tubing is made of nylon that’s specially formulated to let currents pass through, preventing static electricity buildup. It’s often used as a safeguard in pressurized air systems. Comparable to UL 94 V-0, the material is flame resistant and delays the spread of flames. It’s opaque, so you cannot see inside.

| ID, mm | OD, mm | Wall Thick., mm | Bend Radius, mm | Max. Pressure | Color | Lg., ft. | Each | |

Opaque Antistatic Nylon Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 5 | 8 | 1.5 | 19 | 170 psi @ 72° F | Black | 65 | 00000000 | 0000000 |

High-Temperature Abrasion-Resistant Soft

Rubber Tubing for Food, Beverage, and Dairy

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 65A)

- Temperature Range: -60° to 450° F

Not only can this tubing handle the highest temperatures of all our soft tubing for food, beverage, and dairy, it also has thick, silicone rubber walls for superior abrasion and crush resistance. Tubing is made of FDA listed materials. Free of plasticizers like DEHP, it won’t impart tastes or odors to the fluid passing through it. Tubing is semi-clear, so you get a limited view inside the line. It is flexible, so it bends easily around objects.

High-Temperature Soft Rubber Tubing for Food and Beverage

Hot food and beverage applications won’t harm this silicone tubing. It is made of FDA listed materials. Tubing is made without plasticizers like DEHP, so it won’t impart tastes or odors to the fluid passing through it. It can handle applications requiring repeated bending and flexing, such as metering (peristaltic) pumps and robotics. It is flexible and bends easily around objects.

Opaque tubing blocks your view, so you cannot see inside the line to monitor flow.

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 65A)

- Temperature Range: -70° to 450° F

Odor-Resistant Soft Rubber Tubing for Food and Beverage

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 50A)

- Temperature Range: -60° to 400° F

- Semi-Clear Silicone Rubber

Silver ions are blended into the walls of this silicone tubing to inhibit the growth of odor-causing microbes. Tubing is suitable for food and beverage applications. Free of plasticizers like DEHP, it won’t impart tastes to the fluid passing through it. Tubing is semi-clear, so you get a limited view of what's flowing through the line. It is flexible, so it bends easily around objects.

Continuous-Flex Soft Plastic and Rubber Tubing for Food, Beverage, and Dairy

Typically used in applications requiring movement, such as metering (peristaltic) pumps and robotics, this tubing can handle repeated bending and flexing. It's also suitable for use with food and beverage. Tubing doesn’t contain plasticizers like DEHP, so it won’t impart tastes or odors to the fluid passing through it.

Rubber tubing meets NSF/ANSI standards for food contact. It is opaque, so you cannot see inside the line. It is semi-flexible, so it is good for gradual bends. All is either Tygon or comparable to Tygon.

- Comparable to Tygon A-60-F

- Flexibility: Semi-Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 60A)

- Temperature Range: -70° to 270° F

Abrasion-Resistant Firm Plastic and Rubber Tubing for Food and Beverage

Tough and durable, this tubing resists abrasion and tearing. It's also suitable for use with food and beverage.

PVC plastic tubing is the most economical option.

PVC plastic/polyurethane rubber tubing can handle higher temperatures than polyethylene tubing, as well as some standard PVC tubing. It is made without plasticizers like DEHP, so it won’t impart tastes or odors to the fluid passing through it.

Clear tubing allows you to easily monitor flow.

Flexible tubing bends easily around objects.

Soft Plastic Tubing for Chemicals

Use this general purpose PVC tubing with a variety of chemicals. Tubing is clear, so you can easily monitor flow. It is flexible, so it bends easily around objects.

PVC tubing is the most economical option.

Tygon PVC tubing can withstand a wider range of chemicals than standard PVC tubing. It has a super-smooth interior that resists product buildup better than standard PVC.

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 60A)

- Temperature Range: -20° to 160° F

High-Temperature Soft Rubber Tubing for Chemicals

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 60A)

- Temperature Range: -10° to 400° F

Made of resilient Viton® fluoroelastomer, this tubing has what it takes to stand up to high temperatures. Soft and flexible, it is commonly used in applications requiring movement, such as metering (peristaltic) pumps and robotics. Tubing has the chemical resistance to handle hydraulic fluid, acids, and other harsh substances. It is opaque, so you cannot see inside the line to monitor flow.

Abrasion-Resistant Soft Rubber Tubing for Chemicals

Made of a blend of durable rubber, this rugged tubing can stand up to the wear and tear caused by abrasion. It has the chemical resistance to withstand a variety of acids and other harsh substances. It can also handle applications requiring repeated bending and flexing, such as metering (peristaltic) pumps and robotics. This tubing is opaque, so you cannot see inside the line to monitor flow. Semi-flexible, it is good for gradual bends. It’s commonly referred to as Tygon tubing, and used to be known as Norprene tubing.

- Comparable to Tygon A-60-G

- Semi-Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 60A)

- Temperature Range: -70° to 270° F

Continuous-Flex Soft Rubber Tubing for Chemicals

- Flexible

- Compatible with Barbed Tube Fittings

- Hardness:

Inch: Soft (Durometer 65A)

Metric: Soft (Durometer 55A) - Temperature Range:

Inch: -70° to 245° F

Metric: -10° to 270° F

Commonly used in applications requiring movement, such as metering (peristaltic) pumps and robotics, this tubing can handle continuous bending and flexing. It has the chemical resistance to withstand a variety of acids and other harsh substances. Tubing is opaque, so you cannot see inside the line to monitor flow.

UV-Resistant Hard Plastic Tubing for Chemicals

Ultraviolet light won’t cause this tubing to degrade or deteriorate.

Teflon® FEP tubing can handle lower temperatures than standard FEP tubing. It also withstands a wider range of chemicals than standard FEP and TPE tubing.

Semi-clear tubing gives you a limited view inside the line.

Semi-flexible tubing is good for gradual bends.

Tubing that meets USP Class VI adheres to specifications for material testing; it is not for use in medical applications. Tubing that meets UL 94 V-0 is flame retardant, so it delays the spread of flames to valuable equipment.

- See table for flexibility

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 55D)

- Temperature Range: -300° to 400° F

Extreme-Temperature Hard Plastic Tubing for Chemicals

- Semi-Flexible

- Compatible with Compression Tube Fittings

- Hard (Durometer 60D)

- Temperature Range: -100° to 500° F

Run acids, coolant, and other harsh chemicals through this PTFE tubing over a wide range of temperatures. It has a smooth interior for unrestricted flow and easy cleaning. Tubing is semi-flexible, so it is good for gradual bends. Not for use in medical applications.

PTFE tubing can be used in vacuum applications.

Teflon® PTFE tubing meets UL 94 V-0 for flame retardance, so it delays the spread of flames to valuable equipment.

Semi-clear tubing gives you a limited view inside the line.

Crack-Resistant Hard Plastic Tubing for Chemicals

You don’t have to worry about this tubing cracking due to stress or impact—even over a wide range of temperatures. Tubing has the chemical resistance to withstand a variety of acids and other harsh substances.

Teflon® PFA tubing can handle higher temperatures than fluoropolymer tubing.

Clear tubing allows you to easily monitor flow.Semi-flexible tubing is good for gradual bends.Tubing that meets USP Class VI adheres to specifications for material testing; it is not for use in medical applications.

High-Temperature Soft Rubber Tubing for Fuel and Lubricants

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 60A)

- Temperature Range: -80° to 450° F

This fluorosilicone rubber tubing can handle the highest temperatures of all of our fuel and lubricant tubing. It meets MIL-R-25988 specifications for material quality. Tubing is opaque, so you cannot see inside the line. It is flexible, so it bends easily around objects.

Soft Plastic Tubing for Fuel and Lubricants

The industry standard for fuel and lubricant applications, this tubing can be used intermittently with petroleum-based products without becoming hard or brittle. Do not use with ethanol-based gasoline. It is flexible, so it bends easily around objects.

Tygon PVC tubing and tubing comparable to Tygon PVC can handle a wider temperature range than standard PVC tubing. Semi-clear tubing gives you a limited view inside the line.

- Comparable to Tygon F-4040-A, except inch sizes

- Flexible

- Compatible with Barbed Tube Fittings

- Hardness:

Inch: Soft (Durometer 65A)

Metric: Soft (Durometer 55A) - Temperature Range:

Inch: -15° to 165° F

Metric: -35° to 165° F

Smooth-Bore Seamless Stainless Steel Tubing

Seamless construction with no weld bead gives this tubing an interior with unrestricted flow. It is stronger than welded tubing and can be flared without splitting.

304 stainless steel has very good corrosion resistance.

316 stainless steel offers excellent corrosion resistance.

Tubing that meets ASTM specifications adheres to international standards for dimensions and materials.

- Temperature Range: -325° to 1500° F

- Bending Method: Tube Bender

- For Use With: Hydraulic Fluid, Oil, Water, Natural Gas, Air

- Compatible Tubing Fittings: see table

Welded Stainless Steel Tubing

When your application does not require a smooth interior, this tubing is an economical choice. It has a weld bead on the inside.

304 stainless steel has very good corrosion resistance.

316 stainless steel offers excellent corrosion resistance.

- Temperature Range: -420° to 600° F

- Bending Method: Tube Bender

Brass Tubing

Frequently used in a wide range of plumbing applications, this tubing holds up well in mildly corrosive environments. Tubing is seamless, so it has a smooth interior for unrestricted flow.