Filter by

OD

Width

Diameter

Idler Type

Tooth Profile

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Bearing Material

Groove Depth

Bearing Seal Type

Flat Belt Idler Pulleys

|

Nylon |

|

Cast Iron |

|

Steel |

|

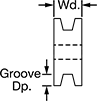

For Belt Wd. | OD | For Shaft Dia. | Dia. | Wd. | Groove Dp. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ball Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3.5" | 3/8" | 3" | 1 3/32" | 0.25" | Nylon | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3.5" | 1/2" | 3" | 1 3/32" | 0.25" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/16" | 2.5" | 0.635" | 2 1/4" | 7/8" | 0.125" | Cast Iron | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 2.8" | 3/8" | 2 33/64" | 1 7/32" | 0.11" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 2.8" | 1/2" | 2 33/64" | 1 7/32" | 0.11" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 3.5" | 3/8" | 3" | 1 7/32" | 0.25" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 3.5" | 1/2" | 3" | 1 7/32" | 0.25" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 2.4" | 3/8" | 2" | 1 5/32" | 0.18" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 2.4" | 1/2" | 2" | 1 5/32" | 0.18" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 3" | 3/8" | 2 1/2" | 1 5/16" | 0.25" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 3" | 1/2" | 2 1/2" | 1 5/16" | 0.25" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 5.6" | 3/8" | 5 1/32" | 1 19/64" | 0.26" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 5.6" | 1/2" | 5 1/32" | 1 19/64" | 0.26" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 29/32" | 4.5" | 3/8" | 4" | 1 25/64" | 0.25" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 29/32" | 4.5" | 1/2" | 4" | 1 25/64" | 0.25" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/16" | 4.5" | 0.635" | 4" | 1 7/16" | 0.25" | Cast Iron | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 2.1" | 3/8" | 1 7/8" | 1 35/64" | 0.09" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 2.1" | 1/2" | 1 7/8" | 1 35/64" | 0.09" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 3.4" | 3/8" | 2 31/32" | 1 43/64" | 0.2" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 3.4" | 1/2" | 2 31/32" | 1 43/64" | 0.2" | Nylon | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/16" | 4.5" | 0.635" | 4" | 2 7/16" | 0.25" | Cast Iron | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/16" | 4.5" | 0.635" | 4" | 3 7/16" | 0.25" | Cast Iron | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | 7" | 1" | 6" | 5" | 0.5" | Cast Iron | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/4" | 7" | 1" | 6" | 6 3/4" | 0.5" | Cast Iron | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Needle Roller Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1.4" | 1/2" | 1 1/8" | 5/8" | 0.125" | Steel | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 1.8" | 1/2" | 1 3/8" | 13/16" | 0.187" | Steel | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/16" | 2.5" | 1" | 2 1/4" | 7/8" | 0.125" | Steel | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/16" | 4.5" | 1" | 4" | 1 7/16" | 0.25" | Cast Iron | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/16" | 4.5" | 1" | 4" | 2 7/16" | 0.25" | Cast Iron | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/16" | 4.5" | 1" | 4" | 3 7/16" | 0.25" | Cast Iron | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | 7" | 1 1/2" | 6" | 5" | 0.5" | Cast Iron | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

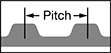

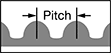

GT Timing Belt Idler Pulleys

|

Toothed |

|

Without Teeth |

|

Toothed | Without Teeth | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Belt Wd., mm | Pitch, mm | For Shaft Dia., mm | OD, mm | Bearing Type | No. of Teeth | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 2MGT Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 2 | 3 | 15 | Ball | 20 | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 2 | 5 | 15 | Ball | 20 | 0000000 | 0000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 2 | 3 | 15 | Ball | 20 | 00000000 | 0000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 2 | 5 | 15 | Ball | 20 | 0000000 | 0000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 2 | 3 | 15 | Ball | 20 | 00000000 | 0000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 2 | 5 | 15 | Ball | 20 | 0000000 | 0000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 8MGT Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 8 | 20 | 90 | Roller | 32 | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 8 | 30 | 100 | Roller | 36 | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 | 8 | 30 | 100 | Roller | 36 | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 14MGT Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37 | 14 | 40 | 146 | Roller | 30 | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Belt Idler Pulleys

|  |  |  |

1 Groove | 2 Grooves | 3 Grooves |

No. of Grooves | OD | For Shaft Dia. | Pitch Dia. | Wd. | Groove Dp. | Material | Body Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For 4L, A, AX Belts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3" | 3/8" | 2" | 45/64" | 0.5" | Nylon | Solid | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3" | 1/2" | 2" | 45/64" | 0.5" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4" | 3/8" | 2.99" | 45/64" | 0.5" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4" | 1/2" | 2.99" | 45/64" | 0.5" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 6" | 1/2" | 5.12" | 23/32" | 0.46" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 7.5" | 1/2" | 6.6" | 23/32" | 0.45" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 5L, B, BX Belts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3.1" | 3/8" | 1.84" | 25/32" | 0.63" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3.1" | 1/2" | 1.84" | 25/32" | 0.63" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4" | 3/8" | 2.84" | 55/64" | 0.58" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4" | 1/2" | 2.84" | 55/64" | 0.58" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 5" | 3/8" | 3.84" | 51/64" | 0.6" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 5" | 1/2" | 3.84" | 51/64" | 0.6" | Nylon | Solid | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 6.3" | 1/2" | 5.18" | 1 23/32" | 0.55" | Nylon | Solid | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 6.3" | 1/2" | 5.18" | 2 7/16" | 0.55" | Nylon | Solid | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Timing Belt Idler Pulleys

|

|

For Max. Belt Wd. | No. of Teeth | Pitch | For Shaft Dia. | OD | Bearing Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For XL Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 24 | 0.2" | 1/2" | 1 1/2" | Roller | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 22 | 0.2" | 1/2" | 1 3/8" | Roller | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For L Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 18 | 0.375" | 1" | 2 1/8" | Roller | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 22 | 0.375" | 1" | 2 5/8" | Roller | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For H Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 16 | 0.5" | 1" | 2 1/2" | Roller | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 16 | 0.5" | 1" | 2 1/2" | Roller | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 18 | 0.5" | 1" | 2 13/16" | Roller | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Belt Idler Pulleys

|  |  |

Brass | Nylon |

For Belt Dia. | OD | For Shaft Dia. | Dia. | Wd. | Groove Dp. | Material | Bearing Material | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 3/32" | 0.8" | 1/8" | 0.654" | 9/64" | 0.048" | Brass | Stainless Steel | 000000 | 000000 | |

| 3/32" | 1" | 1/8" | 0.904" | 5/32" | 0.048" | Brass | Stainless Steel | 000000 | 00000 | |

| 3/32" | 1.5" | 1/8" | 1.404" | 5/32" | 0.048" | Brass | Stainless Steel | 000000 | 00000 | |

| 1/8" | 1" | 1/4" | 0.872" | 3/16" | 0.064" | Brass | Stainless Steel | 000000 | 00000 | |

| 1/8" | 1.5" | 1/4" | 1.372" | 3/16" | 0.064" | Brass | Stainless Steel | 000000 | 00000 | |

| 1/8" | 1.5" | 1/4" | 1.372" | 13/64" | 0.064" | Brass | Stainless Steel | 000000 | 00000 | |

| 1/8" | 2" | 1/4" | 1.872" | 13/64" | 0.064" | Brass | Stainless Steel | 000000 | 00000 | |

| 3/16" | 2" | 3/8" | 1.81" | 9/32" | 0.095" | Brass | Stainless Steel | 000000 | 00000 | |

| 3/16" | 2.5" | 3/8" | 2.31" | 9/32" | 0.095" | Brass | Stainless Steel | 0000000 | 00000 | |

| 1/4" | 4.5" | 3/8" | 3.74" | 55/64" | 0.36" | Nylon | Steel | 00000000 | 00000 | |

| 1/4" | 4.5" | 1/2" | 3.74" | 55/64" | 0.36" | Nylon | Steel | 00000000 | 00000 | |

| 1/4" | 6" | 3/8" | 5.2" | 51/64" | 0.4" | Nylon | Steel | 00000000 | 00000 | |

| 1/4" | 6" | 1/2" | 5.2" | 51/64" | 0.4" | Nylon | Steel | 00000000 | 00000 | |

| 3/8" | 3.1" | 3/8" | 2.45" | 39/64" | 0.3" | Nylon | Steel | 00000000 | 00000 | |

| 3/8" | 3.1" | 1/2" | 2.45" | 39/64" | 0.3" | Nylon | Steel | 00000000 | 00000 | |

| 3/8" | 3.5" | 3/8" | 2.75" | 49/64" | 3/8" | Nylon | Steel | 00000000 | 00000 | |

| 3/8" | 3.5" | 1/2" | 2.75" | 49/64" | 3/8" | Nylon | Steel | 00000000 | 00000 | |

| 3/8" | 5.5" | 3/8" | 4.62" | 9/16" | 0.44" | Nylon | Steel | 00000000 | 00000 | |

| 3/8" | 5.5" | 1/2" | 4.62" | 9/16" | 0.44" | Nylon | Steel | 00000000 | 00000 | |

| 11/16" | 4.8" | 3/8" | 4" | 1 1/16" | 0.41" | Nylon | Steel | 00000000 | 00000 | |

| 11/16" | 4.8" | 1/2" | 4" | 1 1/16" | 0.41" | Nylon | Steel | 00000000 | 00000 |

HTD Timing Belt Idler Pulleys

|

|

For Max. Belt Wd., mm | No. of Teeth | Pitch, mm | For Shaft Dia. | OD | Bearing Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For H8M Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 19 | 8 | 1" | 1 7/8" | Roller | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conveyor Chain Belt Idler Pulleys

For Belt Series No. | For Shaft Dia. | No. of Teeth | OD | Wd. | Material | Color | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

One Piece | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 810, 815, 820 | 1" | — | 5.10" | 2.32" | Nylon | Black | 32 to 190 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 810, 815, 820 | 1" | — | 6.08" | 2.32" | Nylon | Black | 32 to 190 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 810, 815, 820 | 1.25" | — | 5.10" | 2.32" | Nylon | Black | 32 to 190 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 810, 815, 820 | 1.25" | — | 6.08" | 2.32" | Nylon | Black | 32 to 190 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two Piece | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 880 | 1" | 12 | 5.80" | 2.30" | Nylon | Black | 32 to 190 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 880 | 1.25" | 12 | 5.80" | 2.30" | Nylon | Black | 32 to 190 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 882 | 1" | 12 | 5.87" | 2.30" | Nylon | Black | 32 to 190 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 882 | 1.25" | 12 | 5.87" | 2.30" | Nylon | Black | 32 to 190 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

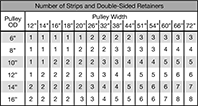

Conveyor Pulley Coatings

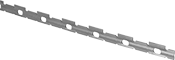

Straight Strips

| |

Straight Profile |

For Pulley Dia. | Lg. | Wd. | Thk. | Hardness | Hardness Rating | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

SBR Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||