About Vacuum Pumps

More

Oil-Free Electric Vacuum Pumps

Generate a vacuum with no risk of oil contamination in your system. These pumps can also create compressed air for powering tools and controlling fluid motion. In vacuum generation, the maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum.

Style B pumps are often used for air and gas sampling, controlling compressed air flow, and vacuum filtration. They are also suitable for pressure applications up to 18 psi, such as light pick-and-place operations.

Barbed connections join quickly and easily in tight spaces with no threading or sealant needed.

Intake | Discharge | O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Max. Pressure, psi | Temp. Range, °F | Volume, dB | Horsepower | Current, A | Connection Style | For Tube ID | Connection Style | For Tube ID | Lg. | Wd. | Ht. | Each | |

NEMA 5-15 Plug | ||||||||||||||||

| B | 20 | 0.6 | 18 | 35° to 100° | 72 | 1/45 hp | 1.2 | Barbed | 3/8" | Barbed | 3/8" | 7 1/4" | 4" | 5 1/2" | 00000000 | 0000000 |

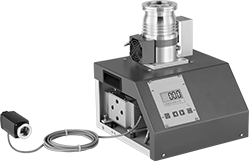

Oil-Free Electric High-Vacuum Pumps

Connect these pumps to a vacuum chamber to create high levels of vacuum—just plug them in and they’re ready to go. Since they don’t use oil, they won’t introduce contaminants into your system. They barely vibrate, which prevents interference with sensitive instruments and measurement devices. These pumps are small enough to fit on a workbench or table. They include both a diaphragm pump and a turbomolecular pump. The turbomolecular pump meets IP54 for protection in damp and dusty environments.

Pumps with claw-clamp intake connections (ISO-K) are rated for high-vacuum chambers. You’ll need a ring and four double-claw clamps (all sold separately) to connect them to other components. They include a gauge with quick-clamp (KF) connections, so you’ll also need a quick clamp and a ring (both sold separately) to connect it to your chamber.

Pumps with flanged intake connections (CF) are rated for ultra-high-vacuum chambers. You’ll need two gaskets (sold separately) to connect to your chamber: one for the intake and one for the included gauge.

Intake Connection | Gauge Port Connection | Discharge Connection (BSPP Threads) | O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum | Max. Flow Rate, cfm | Volume, dBA | Current, A | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Pipe Size | Gender | Ht. | Wd. | Each | |

Claw-Clamp Intake Connection—High Vacuum Rating | |||||||||||||||||

120V AC/240V AC, Single Phase | |||||||||||||||||

| 10 -8 torr @ 72° F | 142 | 50 | 4.6 | 2 1/2" | 3 3/4" | 63 | ISO-K | 1" | 1.57" | 25 | ISO-KF | 1/8 | Male | 13 5/8" | 11 7/8" | 000000 | 000000000 |

Flanged Intake Connection—Ultra-High Vacuum Rating | |||||||||||||||||

120V AC/240V AC, Single Phase | |||||||||||||||||

| 10 -12 torr @ 72° F | 142 | 50 | 4.6 | 2 1/2" | 4 1/2" | 63 | CF | 1 1/2" | 2 3/4" | 40 | CF | 1/8 | Male | 13 7/8" | 11 7/8" | 000000 | 00000000 |

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Each | |

For Claw-Clamp Intake Connection—Double-Claw with Bolt | |||||||

|---|---|---|---|---|---|---|---|

| 2 1/2", 3", 4" | 3.74", 4.33", 5.12" | 63, 80, 100 | ISO-K | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

For Quick-Clamp Gauge Connection—Clamp with Wing Nut | |||||||

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

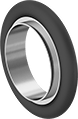

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | O-Ring | Inner Ring | Max. Vacuum | Max. Temp., °F | Each | |

For Claw-Clamp Intake Connection | |||||||||

| 2 1/2" | 3.74" | 63 | ISO-K | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 400° | 0000000 | 000000 |

For Quick-Clamp Gauge Connection | |||||||||

| 1" | 1.57" | 25 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 300° | 0000000 | 00000 |

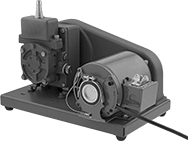

Electric Vacuum Pumps

| NEMA 5-15 |

NEMA 6-15 |

Use these pumps in applications such as degassing and servicing refrigeration and freezer systems. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow.

Intake | Discharge | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum | Max. Flow Rate, cfm | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Port Size | Tube Connection Type | Gender | Pipe Size | Thread Type | Gender | Lg. | Wd. | Ht. | Oil Capacity, oz. | Each | |

115V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||

NEMA 5-15 Plug | |||||||||||||||||

| 10 -2 torr @ 72° F | 3 | 30° to 180° | 70 | 1/2 hp | 7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 27 | 0000000 | 0000000 |

| 10 -2 torr @ 72° F | 5 | 30° to 180° | 70 | 1/2 hp | 7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 21 | 0000000 | 000000 |

| 10 -2 torr @ 72° F | 7 | 30° to 180° | 70 | 1/2 hp | 7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 23 | 0000000 | 000000 |

| 10 -2 torr @ 72° F | 10 | 30° to 180° | 70 | 1/2 hp | 7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 26 | 0000000 | 000000 |

115V AC/230V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||

NEMA 6-15 Plug | |||||||||||||||||

| 10 -2 torr @ 72° F | 3 | 30° to 180° | 70 | 1/2 hp | 3.5/7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 27 | 0000000 | 000000 |

| 10 -2 torr @ 72° F | 5 | 30° to 180° | 70 | 1/2 hp | 3.5/7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 21 | 0000000 | 000000 |

| 10 -2 torr @ 72° F | 7 | 30° to 180° | 70 | 1/2 hp | 3.5/7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 21 | 0000000 | 000000 |

| 10 -2 torr @ 72° F | 10 | 30° to 180° | 70 | 1/2 hp | 3.5/7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 16" | 5 5/8" | 12" | 26 | 0000000 | 000000 |

Electric High-Vacuum Pumps

Achieve powerful vacuum and continuous flow for applications such as vacuum drying, solvent evaporation, and distillation. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow.

Intake | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum | Max. Flow Rate, cfm | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Connection Style | Gender | For Tube ID | Discharge Connection Style | Lg. | Wd. | Ht. | Oil Capacity, qt. | Each | |

120V AC, Single Phase—Without Thermal Overload Protection | |||||||||||||||

NEMA 5-15 Plug | |||||||||||||||

| 10 -4 torr @ 72° F | 0.9 | 50° to 100° | 54 | 1/3 hp | 5 | Barbed | Male | 7/16" | Open Outlet | 17 7/8" | 9" | 12 5/8" | 0.63 | 0000000 | 000000000 |

| 10 -4 torr @ 72° F | 3.2 | 50° to 100° | 54 | 1/2 hp | 7 | Barbed | Male | 7/16" | Open Outlet | 20" | 12" | 15" | 2.25 | 0000000 | 00000000 |

| 10 -4 torr @ 72° F | 5.6 | 50° to 100° | 54 | 1/2 hp | 7 | Barbed | Male | 13/16" | Open Outlet | 20" | 12" | 15" | 2.25 | 0000000 | 00000000 |

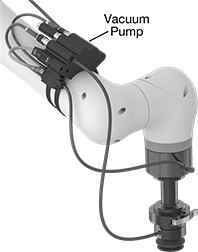

Robot-Arm-Mounted Electric Vacuum Pumps

Generate the suction you need to power end-of-arm tools, such as vacuum cups and grippers, without using an installed vacuum system. These pumps, also known as venturi devices, connect to any compressed air source and come with all the electrical connections you need to start lifting or moving objects. They’re curved and have a foam mounting pad that fits collaborative robot arms. Use the hook-and-loop straps to secure them in place—close to your tools, but out of the way.

These pumps have a vacuum switch that uses analog and PNP digital feedback to send information about the pump’s vacuum level to your controller. The switch has an LED display that shows the vacuum setting and status. Push buttons on the pump let you set and change the vacuum setting. An integrated solenoid valve controls the air flow to your tools.

Vacuum pumps with a discharge tube have an additional integrated solenoid valve that creates a burst of air for removing parts that may not drop when the air flow stops, such as those with adhesive on them.

Vacuum pumps with M8 plug will work with FANUC CRX and Universal Robots models. They include a USB flash drive with software for Universal Robots, called URCap, that plugs into your teach pendant to program the pump.

Intake, Push to Connect | Vacuum Connection, Push to Connect | O'all | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum | Max. Flow Rate, cfm | Operating Pressure, psi | Temp. Range, °F | Volume, dBA | Current, A | Tube OD, mm | Gender | Tube OD, mm | Gender | Lg. | Ht. | For Robot Arm Manufacturer (Series/Model No.) | Each | |

24V DC, Single Phase | ||||||||||||||

With Wire Leads | ||||||||||||||

| 27 in. of Hg @ 72° F | 5 | 120 | 0° to 120° | 70 | 0.17 | 6 | Female | 6 | Female | 4 3/8" | 5 5/8" | __ | 0000000 | 0000000 |

With M8 Plug | ||||||||||||||

| 27 in. of Hg @ 72° F | 5 | 120 | 0° to 120° | 70 | 0.17 | 6 | Female | 6 | Female | 4 3/8" | 5 5/8" | FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 0000000 | 000000 |

Intake, Push to Connect | Discharge, Push to Connect | Vacuum Connection, Push to Connect | O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum | Max. Flow Rate, cfm | Operating Pressure, psi | Temp. Range, °F | Volume, dBA | Current, A | Tube OD, mm | Gender | Tube OD, mm | Gender | Tube OD, mm | Gender | Lg. | Ht. | For Robot Arm Manufacturer (Series/Model No.) | Each | |

24V DC, Single Phase | ||||||||||||||||

With Wire Leads | ||||||||||||||||

| 18 in. of Hg @ 72° F | 5 | 120 | 0° to 120° | 74 | 0.17 | 6 | Female | 6 | Female | 10 | Female | 4 3/8" | 7" | __ | 0000000 | 0000000 |

With M8 Plug | ||||||||||||||||

| 18 in. of Hg @ 72° F | 5 | 120 | 0° to 120° | 74 | 0.17 | 6 | Female | 6 | Female | 10 | Female | 4 3/8" | 7" | FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 0000000 | 000000 |

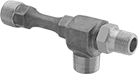

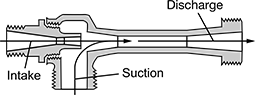

Steam-Powered Jet Pumps

Use plant steam to pump liquids and gases, prime pumps, and remove fumes. When high-pressure steam enters the intake, it creates suction that draws a second liquid or gas into the pump body and discharges a pressurized blend of the two. The discharge pressure is greater than the suction flow but lower than the intake pressure. Gas suction flow is calculated using steam at atmospheric pressure. They have no moving parts or seals, eliminating downtime for lubrication and repairs. They're also known as eductors, ejectors, and injectors.

Note: Liquid suction flow rate is calculated using 80 psi steam at 0-40 feet of discharge head.

Bronze is more corrosion resistant than steel.

316 stainless steel pumps provide the most corrosion resistance.

Liquid Suction Flow Rate, gpm | Gas Suction Flow, cfm | Intake Pressure, psi | Suction | Intake | Discharge | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 5 ft. of Lift | 10 ft. of Lift | @ 20 ft. of Lift | @ 20 psi Steam | @ 50 psi Steam | @ 80 psi Steam | Max. Suction Lift, ft. | For Liquids | For Gases | Temp. Range, °F | Pipe Size | Thread Type | Pipe Size | Thread Type | Pipe Size | Thread Type | Lg. | Wd. | Each | |

For Use With Air, Inert Gas, Steam, Water | |||||||||||||||||||

Steel | |||||||||||||||||||

| 6 | 5 | 3 | 5 | 4 | 3 | 20 | 35-150 | 20-80 | -20° to 150° | 1/2 | NPT | 3/8 | NPT | 1/2 | NPT | 4 1/2" | 1 1/8" | 0000000 | 0000000 |

| 10 | 9 | 5 | 8 | 6 | 6 | 20 | 35-150 | 20-80 | -20° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 17 | 15 | 9 | 14 | 11 | 10 | 20 | 35-150 | 20-80 | -20° to 150° | 1 | NPT | 3/4 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 31 | 27 | 15 | 24 | 20 | 17 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/4 | NPT | 1 | NPT | 1 1/4 | NPT | 9" | 2 3/8" | 0000000 | 000000 |

| 51 | 44 | 25 | 40 | 32 | 28 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 000000 |

| 93 | 80 | 46 | 73 | 58 | 51 | 20 | 35-150 | 20-80 | -20° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 000000 |

Bronze | |||||||||||||||||||

| 6 | 5 | 3 | 5 | 4 | 3 | 20 | 35-150 | 20-80 | -20° to 150° | 1/2 | NPT | 3/8 | NPT | 1/2 | NPT | 4 1/2" | 1 1/8" | 0000000 | 000000 |

| 10 | 9 | 5 | 8 | 6 | 6 | 20 | 35-150 | 20-80 | -20° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 17 | 15 | 9 | 14 | 11 | 10 | 20 | 35-150 | 20-80 | -20° to 150° | 1 | NPT | 3/4 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 31 | 27 | 15 | 24 | 20 | 17 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/4 | NPT | 1 | NPT | 1 1/4 | NPT | 9" | 2 3/8" | 0000000 | 000000 |

| 51 | 44 | 25 | 40 | 32 | 28 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 000000 |

| 93 | 80 | 46 | 73 | 58 | 51 | 20 | 35-150 | 20-80 | -20° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 000000 |

316 Stainless Steel | |||||||||||||||||||

| 6 | 5 | 3 | 5 | 4 | 3 | 20 | 35-150 | 20-80 | -150° to 150° | 1/2 | NPT | 3/8 | NPT | 1/2 | NPT | 4 1/2" | 1 1/8" | 0000000 | 000000 |

| 10 | 9 | 5 | 8 | 6 | 6 | 20 | 35-150 | 20-80 | -150° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 17 | 15 | 9 | 14 | 11 | 10 | 20 | 35-150 | 20-80 | -150° to 150° | 1 | NPT | 3/4 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 51 | 44 | 25 | 40 | 32 | 28 | 20 | 35-150 | 20-80 | -150° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 00000000 |

| 93 | 80 | 46 | 73 | 58 | 51 | 20 | 35-150 | 20-80 | -150° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 00000000 |