Filter by

Thread Size

Threaded Insert Type

Key-Locking Insert Wall Type

For Tap Type

Thread Direction

Number of Locking Keys

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Tensile Strength

Helical Insert Type

About Threaded Inserts

Choose the right threaded insert for your application and learn how to install it securely.

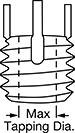

Key-Locking Threaded Insert Assortments with Installation Tools

No. of Inserts Included | Includes | Thread Spacing | For Tap Thread Size | Drill Bit Size | For Max. Hole Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard Wall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phosphate-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 77 | 1"-12 Thread × 1 3/8" Installed Lg. (2 Each) 1/2"-20 Thread × 5/8" Installed Lg. (6 Each) 1/4"-28 Thread × 3/8" Installed Lg. (20 Each) 3/4"-16 Thread × 1 1/8" Installed Lg. (3 Each) 3/8"-24 Thread × 1/2" Installed Lg. (10 Each) 5/16"-24 Thread × 0.438" Installed Lg. (15 Each) 5/8"-18 Thread × 7/8" Installed Lg. (3 Each) 7/16"-20 Thread × 5/8" Installed Lg. (10 Each) 7/8"-14 Thread × 1 1/4" Installed Lg. (3 Each) 9/16"-18 Thread × 0.813" Installed Lg. (5 Each) Installation Tool | Fine | 7/16"-14 1/2"-13 9/16"-12 5/8"-11 3/4"-16 7/8"-14 1 1/8"-12 1 1/4"-12 1 3/8"-12 | 29/64" 33/64" 37/64" 45/64" 53/64" 1 1/16" 1 3/16" 1 5/16" X | 0.397" 0.453" 0.516" 0.578" 0.703" 0.828" 1.063" 1.186" 1.313" | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 77 | 1"-8 Thread × 1 3/8" Installed Lg. (2 Each) 1/2"-13 Thread × 5/8" Installed Lg. (6 Each) 1/4"-20 Thread × 3/8" Installed Lg. (20 Each) 3/4"-10 Thread × 1 1/8" Installed Lg. (3 Each) 3/8"-16 Thread × 1/2" Installed Lg. (10 Each) 5/16"-18 Thread × 0.438" Installed Lg. (15 Each) 5/8"-11 Thread × 7/8" Installed Lg. (3 Each) 7/16"-14 Thread × 5/8" Installed Lg. (10 Each) 7/8"-9 Thread × 1 1/4" Installed Lg. (3 Each) 9/16"-12 Thread × 0.813" Installed Lg. (5 Each) Installation Tool | Coarse | 7/16"-14 1/2"-13 9/16"-12 5/8"-11 3/4"-16 7/8"-14 1 1/8"-12 1 1/4"-12 1 3/8"-12 | 29/64" 33/64" 37/64" 45/64" 53/64" 1 1/16" 1 3/16" 1 5/16" X | 0.397" 0.453" 0.516" 0.578" 0.703" 0.828" 1.063" 1.186" 1.313" | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 77 | 1"-12 Thread × 1 3/8" Installed Lg. (2 Each) 1/2"-20 Thread × 5/8" Installed Lg. (6 Each) 1/4"-28 Thread × 3/8" Installed Lg. (20 Each) 3/4"-16 Thread × 1 1/8" Installed Lg. (3 Each) 3/8"-24 Thread × 1/2" Installed Lg. (10 Each) 5/16"-24 Thread × 0.438" Installed Lg. (15 Each) 5/8"-18 Thread × 7/8" Installed Lg. (3 Each) 7/16"-20 Thread × 5/8" Installed Lg. (10 Each) 7/8"-14 Thread × 1 1/4" Installed Lg. (3 Each) 9/16"-18 Thread × 0.813" Installed Lg. (5 Each) Installation Tool | Fine | 7/16"-14 1/2"-13 9/16"-12 5/8"-11 3/4"-16 7/8"-14 1 1/8"-12 1 1/4"-12 1 3/8"-12 | 29/64" 33/64" 37/64" 45/64" 53/64" 1 1/16" 1 3/16" 1 5/16" X | 0.397" 0.453" 0.516" 0.578" 0.703" 0.828" 1.063" 1.186" 1.313" | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 77 | 1"-8 Thread × 1 3/8" Installed Lg. (2 Each) 1/2"-13 Thread × 5/8" Installed Lg. (6 Each) 1/4"-20 Thread × 3/8" Installed Lg. (20 Each) 3/4"-10 Thread × 1 1/8" Installed Lg. (3 Each) 3/8"-16 Thread × 1/2" Installed Lg. (10 Each) 5/16"-18 Thread × 0.438" Installed Lg. (15 Each) 5/8"-11 Thread × 7/8" Installed Lg. (3 Each) 7/16"-14 Thread × 5/8" Installed Lg. (10 Each) 7/8"-9 Thread × 1 1/4" Installed Lg. (3 Each) 9/16"-12 Thread × 0.813" Installed Lg. (5 Each) Installation Tool | Coarse | 7/16"-14 1/2"-13 9/16"-12 5/8"-11 3/4"-16 7/8"-14 1 1/8"-12 1 1/4"-12 1 3/8"-12 | 29/64" 33/64" 37/64" 45/64" 53/64" 1 1/16" 1 3/16" 1 5/16" X | 0.397" 0.453" 0.516" 0.578" 0.703" 0.828" 1.063" 1.186" 1.313" | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Key-Locking Threaded Inserts for Soft Metal

Inserts | Installation Tools | Inserts with Installation Tools | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | 1-9 | 10-Up | Each | No. of Inserts Included | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Wall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phosphate-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.188" | 4 | 000000000 | 000000 | 000000 | 000000000 | 000000 | 3 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.188" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | 1 5/8"-12 | 1.813" | — | 1.563" | 4 | 000000000 | 00000 | 00000 | 000000000 | 000000 | 2 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.188" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.188" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra-Thick Wall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phosphate-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4"-12 | 1.125" | 1 3/16" | 1.188" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 1 1/4"-12 | 1.125" | 1 3/16" | 1.188" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4"-12 | 1.125" | 1 3/16" | 1.188" | 4 | 000000000 | 000000 | 00000 | 000000000 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 1 1/4"-12 | 1.125" | 1 3/16" | 1.188" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mil.-Spec. Key-Locking Threaded Inserts For Soft Metal

|

Inserts | Installation Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Specs. Met | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Wall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Cadmium-Plated Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.187" | 4 | MS51831A110 | 000000000 | 000000 | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.192" | 4 | MS51831-110 | 000000000 | 00000 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.192" | 4 | MS51831-210 | 000000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra-Thick Wall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4"-12 | 1.125" | 1 3/16" | 1.192" | 4 | MS51832-109 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

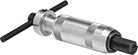

Helical Threaded Insert Removal Tools

|

For Thread Size | Mfr. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard Profile | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9, 7/8"-14, 1"-8, 1"-12, 1"-14, 1 1/8"-7, 1 1/8"-12, 1 1/4"-7, 1 1/4"-12, 1 3/8"-6, 1 3/8"-12, 1 1/2"-6, 1 1/2"-12, M20, M22, M24, M26, M27, M30, M33, M36, M39 | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Narrow Profile | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8"-7, 1 1/8"-12, 1 1/4"-7, 1 1/4"-8, 1 1/4"-12, 1 3/8"-6, 1 3/8"-12, 1 1/2"-6, 1 1/2"-8, 1 1/2"-12, M27, M30, M36, M39 | Heli-Coil | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Key-Locking Threaded Insert Drivers

Key-Locking Threaded Inserts with Installation Tools

Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | No. of Inserts Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard Wall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phosphate-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.188" | 4 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.188" | 4 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | 1 5/8"-12 | 1.813" | — | 1.563" | 4 | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 1 1/4"-12 | 1.250" | 1 3/16" | 1.188" | 4 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra-Thick Wall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phosphate-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4"-12 | 1.125" | 1 3/16" | 1.188" | 4 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Key-Locking Threaded Insert Installation Tools

Screw-Locking Seize-Resistant Key-Locking Threaded Inserts for Soft Metal

Inserts | Installation Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Specs. Met | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Wall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Film-Lubricated 18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 1 1/4"-12 | 1.375" | 1 3/16" | 1.188" | 4 | MS51831-110L | 000000000 | 000000 | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 1 1/4"-12 | 1.375" | 1 3/16" | 1.188" | 4 | MS51831-210L | 000000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hollow Plugs

|

For ID | For Pipe Size | For Thread Size | Ht. | Max. Temp., ° F | Color | Flange Dia. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vinyl Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.29" | 1 | 1 1/4"-12 | 7/8" | 180 | Red | 1 17/32" | 100 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

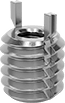

Helical Threaded Inserts

Inserts | Through-Hole Taps | Closed-End Hole Taps | Installation Tools | Inserts with Installation Tools | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | Specs. Met | Pkg. Qty. | Pkg. | Each | Each | Each | No. of Inserts Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pronged | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | 1.250" | 1 9/32" | 1.281" | MS124667 | 1 | 000000000 | 000000 | 000000000 | 0000000 | 000000000 | 0000000 | 000000000 | 0000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | 1.875" | 1 9/32" | 1.281" | MS124707 | 1 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 | 4 | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tube End Weld Nuts

Finish-Your-Own Key-Locking Threaded Inserts for Soft Metal

Helical Threaded Inserts with Installation Tools

Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Inserts Included | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pronged | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | 1.875" | 1 9/32" | 1.281" | 4 | Drill Bit Installation Tool Through-Hole Tap | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

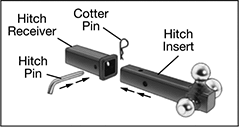

Hitch Balls

|

For Max. Trailer Wt., lb. | Hitch Ball Dia. | Thread Size | Stud Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Chrome-Plated Steel Hitch Balls | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10,000 | 2 5/16" | 1 1/4"-12 | 2 1/8" | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Left-Hand-Thread Tube End Weld Nuts

Easy-Start Helical Threaded Insert Installation Tools

Threaded Insert Installation Tools with Depth Stop

For Thread Size | Mfr. | Handle Style | Helical Insert Tool Drive Type | For Use With | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard (UN) Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | Heli-Coil | T-Handle | Threaded | Helical Inserts, Screw-Locking Helical Inserts | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hitch Inserts

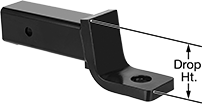

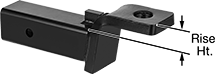

Height Adapters for Hitch Balls

|  |

(Shown in Drop Position) | (Shown in Raise Position) |

For Max. Trailer Wt., lb. | Vert. Cap., lb. | Drop Ht. | Rise Ht. | Overall Dp. | For Hitch Receiver Size | For Hitch Ball Thread Size | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,000 | 1,200 | 3 1/2" | 2" | 10 1/2" | 2 1/2" Square | 1 1/4"-12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,000 | 1,200 | 5" | 3 1/2" | 10 1/2" | 2 1/2" Square | 1 1/4"-12 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,000 | 1,200 | 6" | 5" | 10 1/4" | 2" Square | 1 1/4"-12 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12,000 | 1,200 | 6 3/4" | 5" | 10 1/2" | 2 1/2" Square | 1 1/4"-12 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reinforced Threaded-Hole Bumpers

Abrasion-Resistant Polyurethane Rubber%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | OD | Ht. | Hardness | Hardness Rating | Color | Temp., ° F | Base Plate Material | Nonmarking | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | 1 1/4" | 3" | 2 3/4" | Durometer 85A | Hard | Red | -40 to 200 | Steel | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Key-Locking Threaded Insert Blank Drivers

|

For Tap Thread Size | Handle Style | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard (UN) Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | Straight | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Squeeze-Release Caps

|

For OD | For Pipe Size | For Thread Size | Inside Ht. | Flexibility | Max. Temp., ° F | Color | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vinyl Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.143" | 1 | 1 1/4"-12 | 5/8" | Flexible | 180 | Red | 100 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||